Mill Finish 4′x8′ Aluminum Sheet: The "Blank Canvas" That Engineers and Fabricators Trust

A Mill Finish 4′x8′ aluminum sheet is often described as "standard stock," but that label hides what makes it powerful. In many fabrication shops, this sheet is the starting point for everything that follows: precision cutting, bending, welding, anodizing, cladding, insulation jacketing, signage, enclosures, tread covers, and general-purpose panels. From a distinctive viewpoint, mill finish is not a "final look" at all-it's a truthful surface that reveals how the metal was made, how it will form, and how reliably it will behave under tools.

When you choose a 4′x8′ aluminum sheet in mill finish, you're choosing a format that balances supply-chain efficiency with real-world usability. The 48" × 96" footprint fits common CNC tables, shear beds, brake tooling, crate dimensions, and jobsite handling. That "quiet compatibility" is why this size is a workhorse across industries.

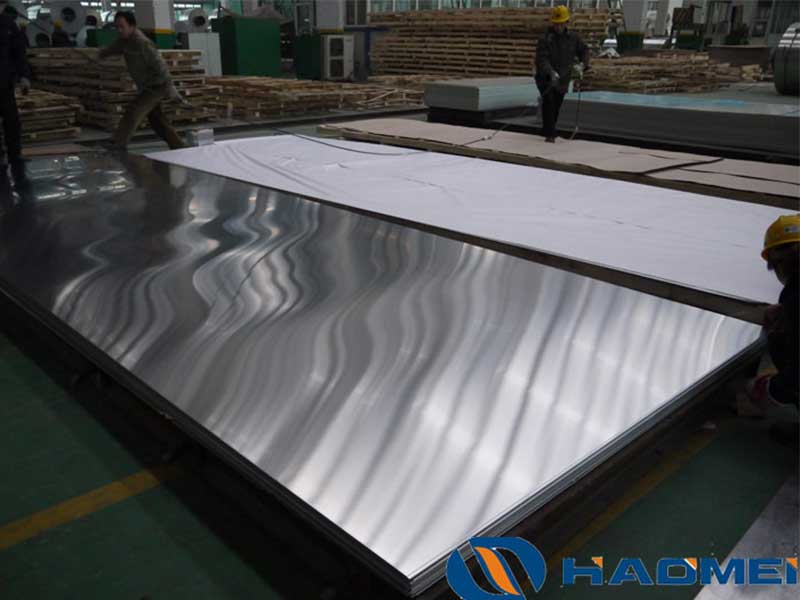

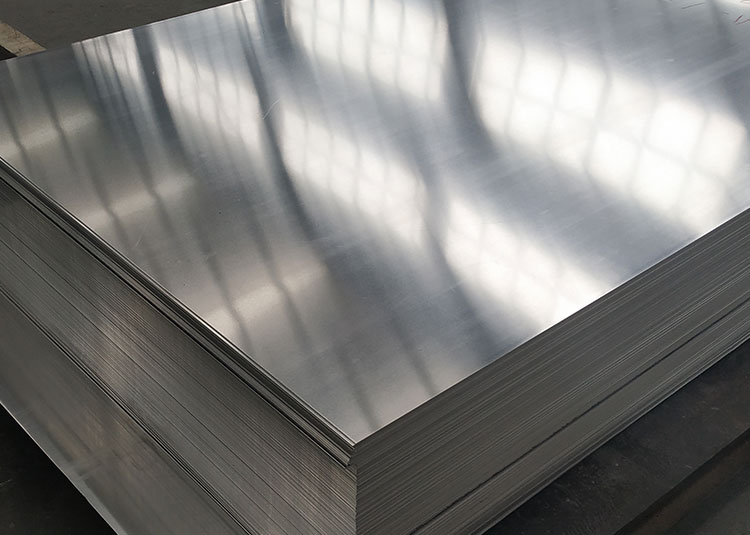

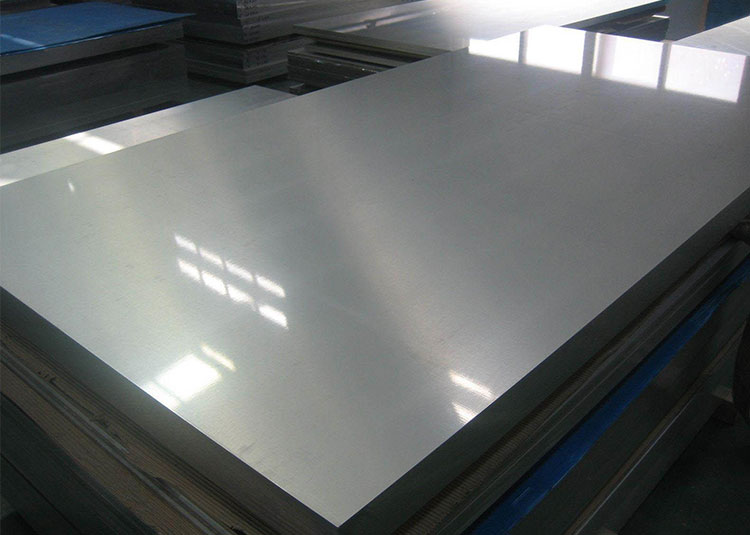

What "Mill Finish" Really Means, Seen Through a Fabricator's Eyes

Mill finish aluminum sheet is delivered with the as-rolled surface straight from the mill. It typically shows subtle rolling lines, slight reflectivity variations, and the kind of honest texture that makes it ideal for downstream processing.

From a production standpoint, mill finish is valuable because it gives you freedom:

It's a natural base for anodizing and painting when proper cleaning and pretreatment are applied

It's easy to mark, scribe, and layout before forming

It's economical compared with pre-polished or pre-coated sheet

It highlights surface issues early, which is useful when appearance isn't the primary driver but performance and consistency are

Mill finish is commonly specified where function matters more than cosmetic uniformity, or where the sheet will be covered, painted, laminated, powder coated, or used internally.

Why 4′x8′ Is the Most "Economical Geometry" in Sheet Aluminum

A 4′x8′ aluminum sheet is not just popular; it's optimized for waste control.

It nests efficiently for rectangles, brackets, gussets, door skins, back panels, and general fabrication blanks

It reduces offcut complexity because many architectural and industrial parts are designed around 48-inch increments

It is easy to handle with standard shop equipment and common lifting methods

This size often provides the best balance between yield, handling safety, and transport cost, especially in mixed fabrication environments.

Typical Parameters for Mill Finish 4′x8′ Aluminum Sheet

Specifications vary by alloy and temper, but these are common order parameters customers use to define exactly what they need.

Sheet size

Width: 48 in (4 ft)

Length: 96 in (8 ft)

Thickness range commonly supplied

0.016 in to 0.250 in (approximately 0.4 mm to 6.35 mm)

Thicker plate-like gauges may be available depending on alloy and production route

Edge condition

Sheared edge is standard

Sawn edges may be available for heavier gauges or tighter edge requirements

Surface condition

Mill finish, as-rolled

Protective PVC film optional (often requested for laser cutting and cosmetic protection during handling)

Flatness considerations

Flatness depends on alloy, thickness, temper, and rolling practice

For critical flatness applications, communicate the fabrication method and tolerance needs early, especially for thin gauges and wide panels

Alloy Selection: Choosing Behavior, Not Just a Number

A unique way to choose aluminum alloy is to think in terms of "behavior under stress," not simply strength.

If your project prioritizes corrosion resistance and forming ease

Alloys like 1050, 1060, 1100, and 3003 are often selected for their excellent workability and clean corrosion performance in many environments.

If your project prioritizes strength-to-weight for structural parts and machining

5052 and 5083 are popular for marine and industrial service, while 6061 is a versatile option often used when machining and moderate forming are required.

If your project prioritizes deep drawing or complex forming

Soft tempers in the 1xxx and 3xxx series are frequently chosen because they flow predictably under dies.

Tempering Conditions: The "Personality Setting" of the Sheet

Temper is not a minor suffix. It defines how the sheet will respond to bending, forming, denting, and springback.

Common tempers for mill finish aluminum sheet include:

O temper (annealed)

Maximum ductility and best forming performance

Often used for deep drawing, tight bends, and parts where cracking must be avoided

H temper (strain-hardened, primarily for non-heat-treatable alloys like 1xxx, 3xxx, 5xxx)

H14 and H32 are widely used in general fabrication

A practical balance of strength and formability

Reduced risk of handling dents compared with O temper

T temper (heat-treated, primarily for heat-treatable alloys like 6061)

T6 is common for stiffness and strength

Not as forgiving for tight radius bending as softer tempers

Choosing temper is essentially choosing how the sheet will "negotiate" with your tooling: softer tempers cooperate with tight bends, harder tempers hold shape and resist deformation.

Implementation Standards and Common Specification References

Mill finish 4′x8′ aluminum sheet is typically supplied to widely recognized standards. The exact standard depends on region, alloy family, and end-use requirements.

ASTM B209

A primary North American standard covering aluminum and aluminum-alloy sheet and plate

Defines chemical composition, mechanical properties, tolerances, and more for many alloys and tempers

EN 485 (Europe)

Commonly referenced for tolerances and mechanical properties for wrought aluminum and aluminum alloys

Often paired with EN AW alloy designations

GB/T standards (China)

GB/T 3880 is a common reference for wrought aluminum and aluminum alloy sheet/strip

If your application includes pressure equipment, transportation, marine exposure, or regulated construction, it is wise to confirm the required standard edition, inspection level, test certificate type, and marking/traceability requirements at the time of ordering.

Chemical Composition: Typical Alloy Chemistry Table (Reference)

Chemical composition is one of the clearest "fingerprints" of aluminum sheet performance. The table below provides typical composition limits for common sheet alloys used in mill finish 4′x8′ aluminum sheet. Actual limits and reporting depend on the governing standard and mill certification.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al |

|---|---|---|---|---|---|---|---|---|---|

| 1100 | ≤ 0.95 (Si+Fe) | - | 0.05–0.20 | ≤ 0.05 | ≤ 0.05 | - | ≤ 0.10 | ≤ 0.05 | Remainder |

| 3003 | ≤ 0.60 | ≤ 0.70 | 0.05–0.20 | 1.00–1.50 | ≤ 0.10 | - | ≤ 0.10 | ≤ 0.15 | Remainder |

| 5052 | ≤ 0.25 | ≤ 0.40 | ≤ 0.10 | ≤ 0.10 | 2.20–2.80 | 0.15–0.35 | ≤ 0.10 | ≤ 0.15 | Remainder |

| 6061 | 0.40–0.80 | ≤ 0.70 | 0.15–0.40 | ≤ 0.15 | 0.80–1.20 | 0.04–0.35 | ≤ 0.25 | ≤ 0.15 | Remainder |

Notes for buyers and engineers

For 1100, silicon and iron are sometimes reported together as a combined limit, depending on the standard and mill practice.

Corrosion behavior, weld response, and anodizing appearance can be affected by trace elements and processing history, not only major alloying elements.

Processing Reality: How Mill Finish Behaves in Cutting, Forming, and Joining

Mill finish 4′x8′ aluminum sheet is a favorite because it's predictable under most shop processes, especially when alloy and temper are matched to the job.

Laser cutting and routing

Clean cuts are common, especially with appropriate assist gas and parameter tuning

Protective film helps reduce handling scratches and smoke staining

Bending and brake forming

Bend radius guidance is strongly tied to temper

O and softer H tempers allow tighter bends with lower crack risk

Harder tempers may need larger inside radii and proper grain direction planning

Welding

5xxx series alloys such as 5052 generally weld well and keep corrosion resistance in many environments

6061 is weldable but will lose strength in the heat-affected zone unless post-weld heat treatment is considered, depending on design requirements

Surface finishing

Mill finish can be anodized or painted, but surface uniformity will reflect the starting finish

If cosmetic perfection is the goal, a brighter or brushed finish, or additional surface prep, may be more suitable

Where Mill Finish 4′x8′ Aluminum Sheet Shines in Real Applications

Mill finish is often the smart choice when the sheet is a functional layer in a system.

Equipment panels and machine guards where durability matters more than cosmetic uniformity

Ducting, insulation jacketing, and general industrial cladding

Tooling plates, jigs, and fixtures where the surface will be drilled and modified

Marine-adjacent fabrications when paired with appropriate alloy selection such as 5052

Sign blanks, backers, and enclosures that will be coated, printed, or laminated

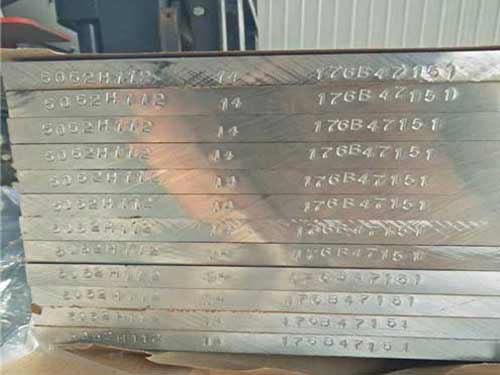

Buying Notes: What to Specify to Get the Right Sheet the First Time

A practical purchase description typically includes:

Alloy and temper, such as 3003-H14, 5052-H32, or 6061-T6

Size: 48" × 96"

Thickness: exact gauge or decimal thickness

Standard: ASTM B209, EN 485, or the relevant local standard

Surface: mill finish, with or without PVC film

Certification requirements: mill test report, heat number traceability if needed

This is how you turn a "commodity sheet" into a controlled input that behaves consistently on the shop floor.