Aluminum sheet stands as a versatile and indispensable material in the packaging industry. Its unique blend of physical and chemical properties has revolutionized packaging solutions, combining efficiency, durability, and sustainability.

The Role and Functions of Packaging Aluminum

Packaging aluminum’s primary roles include protection, preservation, presentation, and convenience across various industries such as food, pharmaceuticals, and cosmetics. Owing to its characteristic lightweight and malleability, aluminum sheets efficiently shield contents from external factors like moisture, oxygen, light, and microbial contamination. Moreover, its excellent barrier properties prolong the shelf life of perishable goods without compromising flavor or nutritional value.

functions:

- Barrier Protection: Aluminum foil forms an impermeable shield against air, light, and moisture.

- Lightweight Strength: High strength-to-weight ratio enables durable packaging with minimal material use.

- Thermal Conductivity: Facilitates rapid heat exchange—ideal for thermal packaging and cooking.

- Recyclability: 100% recyclable with no loss in quality, supporting sustainable packaging initiatives.

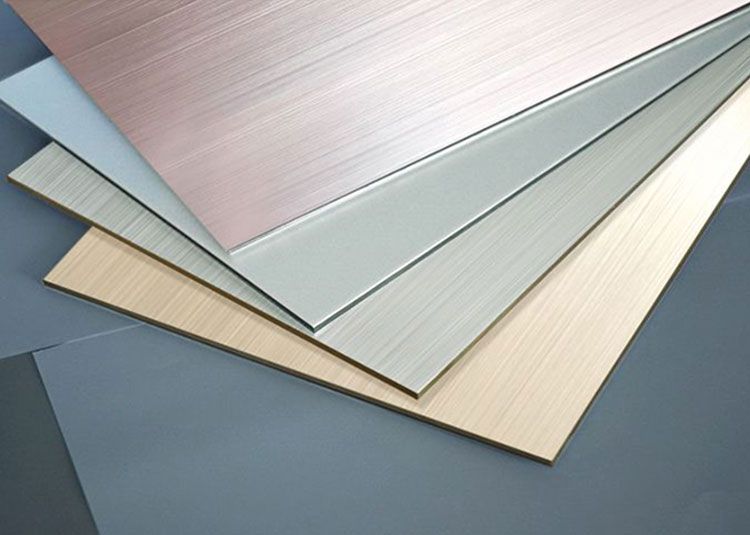

- Aesthetic Appeal: Smooth metallic surface facilitates printing, embossing, and attracting consumer attention.

Common Applications of Aluminum in Packaging

- Food Industry: Wrappers, trays, and laminated sheets prevent spoilage and contamination for confectionery, bakery items, ready-to-eat meals, and beverages.

- Pharmaceuticals: Utilizing aluminum blisters and packets enhances drug protection against humidity and UV.

- Cosmetics: Cream jars and tubes benefit from the metal's inertness and pristine finish.

- Industrial Items: Protective wraps safeguard delicate electronic components and machinery parts.

Technical Details: Alloy Specifications and Tempering

Packaging aluminum is usually produced using specific alloys and tempers to balance flexibility, strength, and corrosion resistance.

| Alloy | Typical Composition (%) | Mechanical Properties | Common Temper | Characteristics |

|---|---|---|---|---|

| 1100 | ≥ 99% Al | Tensile strength: ~65 MPa | O (Annealed) | Excellent ductility; used in foil |

| 3003 | Al 96.8%, Mn 1.2% | Tensile strength: ~130 MPa | H14 (Half Hard) | Medium strength; good formability |

| 8011 | Al with Mn and Fe traces | Tensile strength: ~105 MPa | H19 (Full Hard) | High corrosion resistance; used for foil and laminates |

- Common Tempers:

- O Temper (Annealed): Soft and highly malleable, ideal for deep drawing and forming complex shapes.

- H Temper: Work-hardened state with increased strength but reduced stretchability (ranges from H14 – half hard, to H19 – full hard). Important in controlling foil thickness to prevent tearing.

Implementation Standards

Aluminum packaging must adhere to stringent international standards ensuring quality and safety. Notable standards include:

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate. It controls alloy compositions, thickness tolerances, mechanical properties, and permissible defect limits.

- ISO 6362-1: Aluminum alloy sheets for flexible packaging production; details tempers, thickness ranges.

- FDA Code of Federal Regulations Title 21: Governs safe usage of aluminum in food-contact packaging.

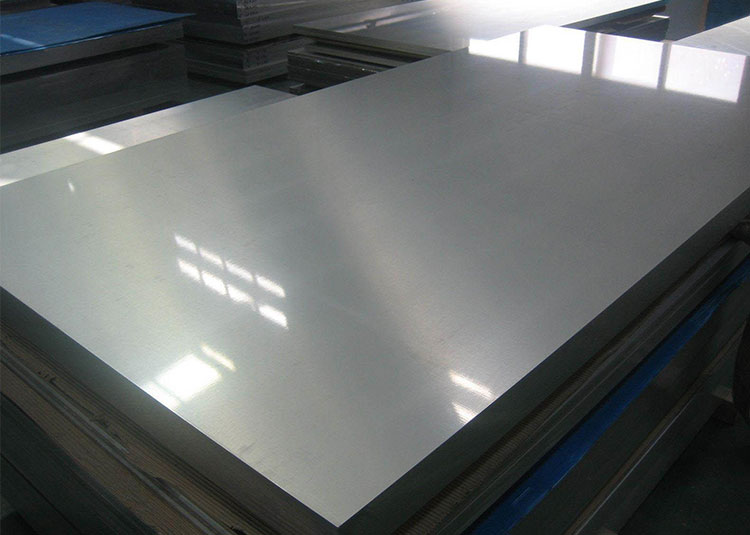

Process control during manufacturing includes tolerance checks on thickness (typically 6 - 30 microns for foil), surface finish (mill finish, bright annealed), and chemistry consistency for alloy integrity.

Chemical Properties Table of Typical Packaging Aluminum Alloys

| Property | Aluminum (1100 Alloy as Reference) |

|---|---|

| Aluminum (Al) | ≥99.0% |

| Silicon (Si) | ≤0.4% |

| Iron (Fe) | ≤0.7% |

| Copper (Cu) | ≤0.05% |

| Manganese (Mn) | ≤0.05% |

| Magnesium (Mg) | ≤0.05% |

| Zinc (Zn) | ≤0.1% |

| Tensile Strength | Approx 65 MPa (annealed) |

| Density | 2.70 g/cm³ |

| Melting Point | 660°C |

| Thermal Conductivity | ~237 W/m·K |

| Corrosion Resistance | Excellent in atmospheric environments |

Chemically inert, aluminum does not react significantly with food products but develops a corrosion-resistant oxide layer that can be optionally enhanced through anodizing to increase durability.