Aluminum sheets are flat, thin pieces of aluminum that provide exceptional versatility and functionality across a wide range of industries. Known for their lightweight characteristics, corrosion resistance, and excellent machinability, aluminum sheets serve as a critical material in manufacturing, construction, transportation, and consumer goods.

What is Aluminum Sheet?

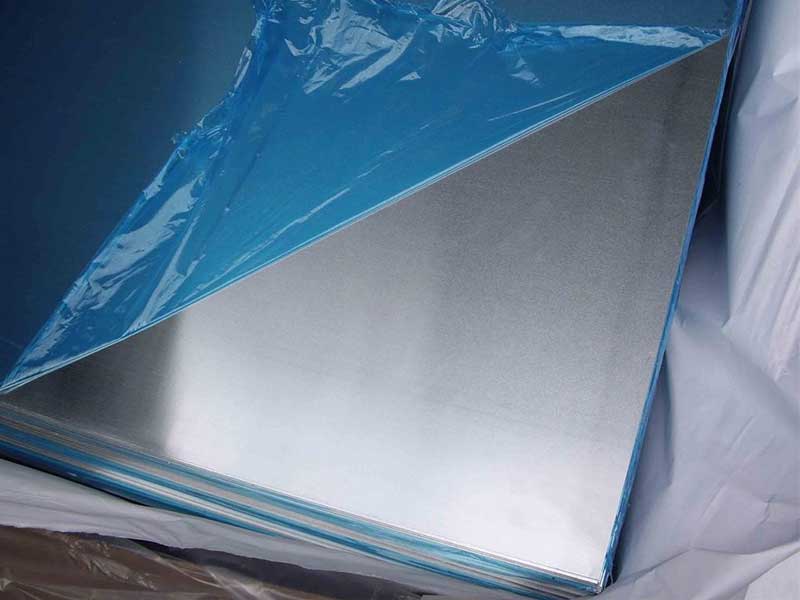

An aluminum sheet is generally defined as a flat-shaped aluminum product with a thickness less than 6mm (0.236 inches). Thicker flat aluminum products exceeding this thickness are often referred to as aluminum plates. Sheets can be fabricated through processes such as rolling and can be produced with a variety of surface finishes to meet aesthetic or functional requirements.

Features of Aluminum Sheets

Lightweight and High StrengthAluminum sheet offers an excellent strength-to-weight ratio. It is about one-third the weight of steel but can be alloyed and heat-treated to achieve higher strength, making aluminum sheets ideal for lightweight yet durable applications.

Corrosion ResistanceAluminum naturally forms a thin oxide layer on its surface, preventing further oxidation and efflorescence. This intrinsic property protects the sheet in many environments, including exposure to moisture and chemicals.

Excellent FormabilityAluminum sheets can be fabricated easily — they are suitable for bending, cutting, stamping, and rolling. This flexibility allows manufacturers to create complex shapes for specialized applications.

Thermal and Electrical ConductivityAluminum sheets provide good conductivity of heat and electricity compared to most other metals, allowing their use in heat exchangers, kitchens, and electrical enclosures.

Recyclability and SustainabilityAluminum is recyclable indefinitely without loss of its qualities, making aluminum sheets sustainable for environmentally friendly designs.

Surface Finish VarietyAluminum sheets are available in polished, brushed, anodized, painted, and embossed finishes to suit aesthetic or functional criteria.

Common Aluminum Alloys for Sheets and Their Chemical Composition

The choice of alloy impacts mechanical properties, corrosion resistance, and processability.

| Alloy Series | Typical Composition (%) | Features | Common Use |

|---|---|---|---|

| 1xxx | ≥99% Al | Exceptionally corrosion resistant, very ductile | Chemical, food packaging, insulation |

| 3xxx | ~1-2% Mn | Good corrosion resistance, cold workable | Roofing, siding, cooking utensils |

| 5xxx | 3-5% Mg | Superior strength, corrosion resistance in marine environments | Marine, automotive panels |

| 6xxx | 0.8-1.2% Mg, 0.4-0.8% Si | Medium strength, good machinability, heat treatable | Structural components, infrastructure |

| 7xxx | 5-8% Zn (+ small Mg, Cu) | Very high strength, less corrosion resistant | Aerospace, high-strength applications |

Typical Physical & Mechanical Properties (Example Alloy 3003-H14 Aluminum Sheet)

| Property | Value |

|---|---|

| Density | 2.73 g/cm³ |

| Tensile Strength | 130-180 MPa |

| Yield Strength | ~110 MPa |

| Elongation at Break | 10-17% |

| Thermal Conductivity | 160-170 W/m·K |

| Electrical Conductivity | ~33% IACS |

| Melting Point | 650°C |

Applications of Aluminum Sheets

1. Construction and Architecture

Aluminum sheets are durable, weather-resistant, and aesthetic. They are widely used for cladding, roofing, ceilings, window frames, elevator panels, and decorative trims.

2. Transportation Industry

Because of their light weight and high strength, aluminum sheets find applications in airplane skins, automotive body panels, railcars, trucks, and ships, helping to reduce fuel consumption and emissions.

3. Packaging

Aluminum sheets are used in food and beverage packaging like cans, wraps, and trays due to their corrosion resistance and non-toxicity.

4. Consumer Goods

Common items such as laptop casings, kitchen utensils, appliances, and furniture parts utilize aluminum sheets for their balance of durability and visual appeal.

5. Electrical and Electronics

In electrical circuits, housings, shields, and heatsinks, aluminum sheets provide efficient heat dissipation and protection, contributing toward system effectiveness and safety.

6. Industrial Applications

The metal is heavily used for ductwork, chemical tanks, heat exchangers, and machine enclosures given its mechanical reliability and corrosion resistance.

How to Select the Right Aluminum Sheet

Consider these factors when choosing aluminum sheets:

- Alloy and Temper: Influences strength, corrosion resistance, and workability.

- Thickness and Dimensions: Depend on load requirements and space constraints.

- Surface treatment: For appearance, environmental resistance, or additional functionality.

- Mechanical specifications: Tensile and yield strength levels as per application.

- Cost-effectiveness and supply chain availability.