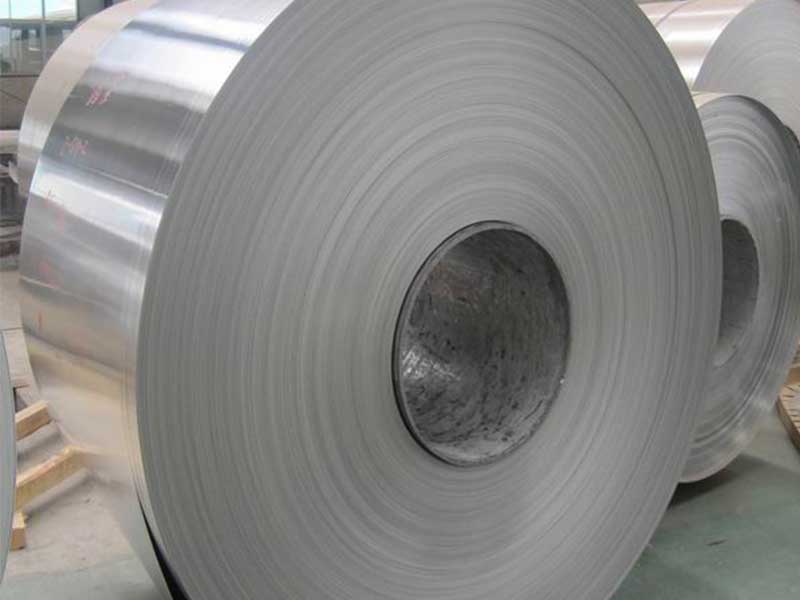

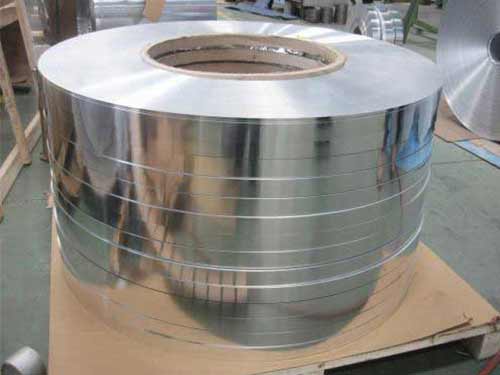

Aluminum strips are narrow-width coils or sheets of aluminum metal manufactured to stringent quality standards. Known for their exceptional strength-to-weight ratio, corrosion resistance, electrical conductivity, and ease of fabrication, aluminum strips find application in packaging, electrical, automotive, and architectural industries.

Aluminum strips are produced from high-quality aluminum alloys, rolled to precise thicknesses typically ranging from 0.2 mm up to 3.0 mm. The width is normally constrained relative to the coil dimensions and intended usage, often between 5 mm to 200 mm. The product’s tempered finish ensures desired mechanical properties suited for processing or end-use.

Chemical Composition and Alloy Designation

Aluminum strips are made from a range of alloys tailored to various engineering requirements. Widely used alloys include series 1xxx, 3xxx, 5xxx, and 8xxx, distinguished by their primary alloying element and metallurgical properties.

Typical Aluminum Alloy Chemical Composition

| Element (%) | 1100 (1xxx) | 3003 (3xxx) | 5052 (5xxx) | 8011 (8xxx) |

|---|---|---|---|---|

| Aluminum (Al) | 99.0 min | 96.8-99.0 | 94.8 min | 89.5-94.5 |

| Copper (Cu) | 0.05 max | 0.10 max | 0.10 max | ≤ 0.22 |

| Manganese (Mn) | 0.05 max | 1.0 - 1.5 | 0.10 max | 0.20-0.80 |

| Magnesium (Mg) | 0.03 max | 0.40 max | 2.2 - 2.8 | 0.10 max |

| Silicon (Si) | 0.40 max | 0.3 - 0.6 | 0.40 max | 0.20 - 0.60 |

| Iron (Fe) | 0.95 max | 0.7 max | 0.40 max | 1.0 max |

| Zinc (Zn) | 0.10 max | 0.10 max | 0.10 max | ≤ 0.10 |

Temper Designations and Mechanical Properties

The temper of aluminum strip influences its mechanical strength and ductility. Common tempering processes include annealing, cold working, and partial hardening to achieve required performance characteristics.

| Temper | Description | Typical Mechanical Strength (MPa) | Remarks |

|---|---|---|---|

| O | Annealed | 40 - 70 | Maximum ductility, lowest strength |

| H12 | Half-hard cold worked | 110 - 150 | Fairly strong, moderate hardness |

| H14 | Quarter-hard cold worked | 130 - 170 | Higher strength, moderate ductility |

| H18 | Full hard cold worked | 190 - 230 | Maximum hardness, minimum ductility |

| T4 | Solution treated + natural aging | 90 - 150 | Heat treated to moderate strength |

| T6 | Solution treated + artificial aging | 200 - 260 | Peak strength for heat treatable alloy |

Manufacturing Standards and Quality Control

Aluminum strips conform to global and regional manufacturing standards ensuring reproducibility, safety, and performance. The applicable standards include but are not limited to:

- ASTM B209/B209M: Standard specification for aluminum and aluminum-alloy sheet and plate.

- EN 485-2: Aluminum and aluminum alloys – Sheet, strip and plate – Mechanical properties.

- JIS H4000: Japanese industrial standards for aluminum sheet products.

- GB T3880: Chinese national standards for aluminum alloy sheets and strips.

Quality control steps generally include:

- Chemical composition analysis.

- Thickness and width checks.

- Mechanical property testing (tensile, elongation).

- Surface defect inspections.

- Coating and finishing process assessment if applicable.

Applications of Aluminum Strip

Thanks to its adaptable properties and light weight, aluminum strip is integral in multiple domains:

- Packaging Industry: Manufacture of foil for food wrapping, tubes, and cans.

- Electrical Industry: Conductors, electric foils for capacitors, and transformers.

- Automotive Industry: Decorative trim strips, heat exchangers, and structural parts.

- Construction: Cladding, siding, and components requiring corrosion resistance.

- Consumer Products: Appliance components, craft items, and hardware.

Aluminum strip is a versatile product engineered to meet precise mechanical and chemical requirements for diverse industrial applications. Selecting the appropriate alloy and temper ensures optimal performance in durability, formability, and corrosion resistance. Adhering to global manufacturing standards guarantees consistent quality that manufacturers and fabricators rely on.

the specifications, alloy properties, and standard designations of aluminum strips helps industries harness aluminum’s remarkable properties efficiently and economically.

For consultation on aluminum strip grades tailored to your specific projects, including custom tempering or surface treatments, contact our technical sales experts.

If you require detailed specifications or guides compliant with your industry standards, we are ready to provide documentation and samples. Unlock the full potential of aluminum strip with expert technical support.