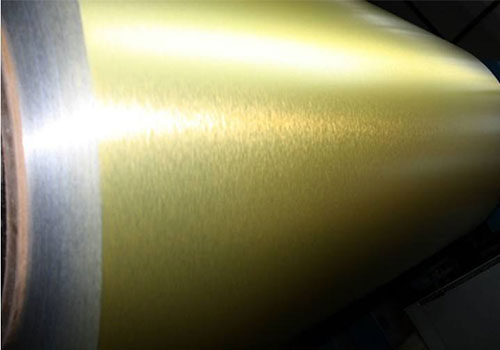

In the rapidly advancing materials industry, coated aluminum sheets have emerged as a beacon of innovation, blending lightweight versatility with enhanced durability and remarkable aesthetic appeal. As an expert aluminum alloy supplier, our focus on coated aluminum sheets integrates cutting-edge alloy tempering and precise implementation standards to meet diverse industrial demands.

What Sets Coated Aluminum Apart: A Technical Insight

Coated aluminum sheets are aluminum alloy substrates bonded with protective or decorative coating layers through specialized processes such as PVDF (Polyvinylidene fluoride), PE (Polyester), or polyamide coatings. This combination optimizes the substrate’s resistance to corrosion, weathering, and mechanical wear while expanding its application scope—from architectural cladding and roofing systems to transportation and electronics.

The Core Alloy: Choosing the Right Temper and Composition

The base metal's composition and tempering govern the coated aluminum sheet's mechanical and physical properties. Common alloy grades include 3003, 3004, 3105, 5052, and 6061, each selected for specific performance criteria. For example:

- 3004 Alloy H14 Temper: Strikingly balanced for robust formability with moderate strength, suitable for exterior facades.

- 3105 Alloy H24 Temper: Offers superior paint adhesion with excellent corrosion resistance.

Tempering involves controlled heating and mechanical processing to enhance the metal’s strength without sacrificing workability. For coated aluminum, the alloy’s temper must be compatible with coating tensions to prevent post-coating deformation or adhesion failures.

Implementation Standards and Testing: Ensuring Quality Consistency

Strict standards guide the manufacturing of coated aluminum sheets. Prominent among these include:

- ASTM B209: Governs aluminum and aluminum-alloy sheet and plate, including specifications for thickness and mechanical properties.

- AAMA 2605: Defines superior performance requirements for fluoropolymer-coated aluminum used in architectural applications, ensuring durability and color retention.

- ISO 9227: Salt spray (fog) corrosion test for evaluating protective coatings’ resilience.

Every coil and sheet batch undergoes rigorous coating adhesion tests (cross-cut tape test), gloss measurement, and accelerated weathering cycles to ensure the coating’s longevity aligns with promised specifications.

Chemical Composition of Selected Aluminum Alloys for Coated Sheets

A pivotal factor influencing coating adherence and corrosion resistance is the aluminum alloy’s chemical composition. Below is a standard composition breakdown for commonly used alloys in coated aluminum sheets:

| Alloy | Si (Silicon) | Fe (Iron) | Cu (Copper) | Mn (Manganese) | Mg (Magnesium) | Zn (Zinc) | Ti (Titanium) | Al (Aluminum) (balance) |

|---|---|---|---|---|---|---|---|---|

| 3003 | 0.6-1.2% | ≤0.7% | ≤0.05% | 1.0-1.5% | ≤0.10% | ≤0.10% | ≤0.15% | Remainder |

| 3004 | 0.6-1.3% | ≤0.7% | ≤0.25% | 1.2-1.8% | ≤0.10% | ≤0.10% | ≤0.15% | Remainder |

| 3105 | 0.6-1.0% | ≤0.6% | ≤0.10% | ∼0.4% | 0.20-0.60% | ≤0.10% | ≤0.15% | Remainder |

| 5052 | ≤0.25% | ≤0.40% | ≤0.10% | ≤0.10% | 2.2-2.8% | ≤0.10% | ≤0.15% | Remainder |

| 6061 | 0.4-0.8% | ≤0.7% | 0.15-0.40% | 0.15-0.40% | 0.8-1.2% | ≤0.25% | ≤0.15% | Remainder |

This composition influences factors pertinent to coating, notably oxidation behavior and surface tension.

Why Coated Aluminum? Advantages from a Metallurgical Standpoint

- Corrosion Resistance: The coating acts as a barrier preventing electrolytic corrosion of the aluminum substrate while alloys like 3004 or 3105 inherently form stable oxide layers for self-healing protection.

- Enhanced Mechanical Strength: Tempering alloys to H14 or H24 tempers ensures minimal structural deformation over time under physical stress while maintaining paint integrity.

- Optimized Surface Adhesion: Polyester or fluoropolymer coatings chemically and physically adhere better where alloying elements are controlled meticulously during furnace processing.

- Dimensional Stability: Temper control mitigates the risk of warping, which could occur due to differing thermal expansion coefficients between both substrate and coating layers.

Applications Encompassing Coated Aluminum

Because of its multifaceted attributes, coated aluminum is preferred across sectors:

- Construction: Façade panels, gutters, and roofing that demand both weather resilience and aesthetic longevity.

- Transportation: Lightweight, antifouling surfaces on buses and trailers that often face abrasive environmental exposure.

- Electronics: Circuit board housings requiring electromagnetic shielding combined with decorative finish and mechanical protection.