When we think of reflective surfaces, glass or polished steel usually comes to mind. However, mirrored aluminum offers a unique alternative, combining lightweight durability and versatility with dazzling reflective qualities.

What is Mirrored Aluminum?

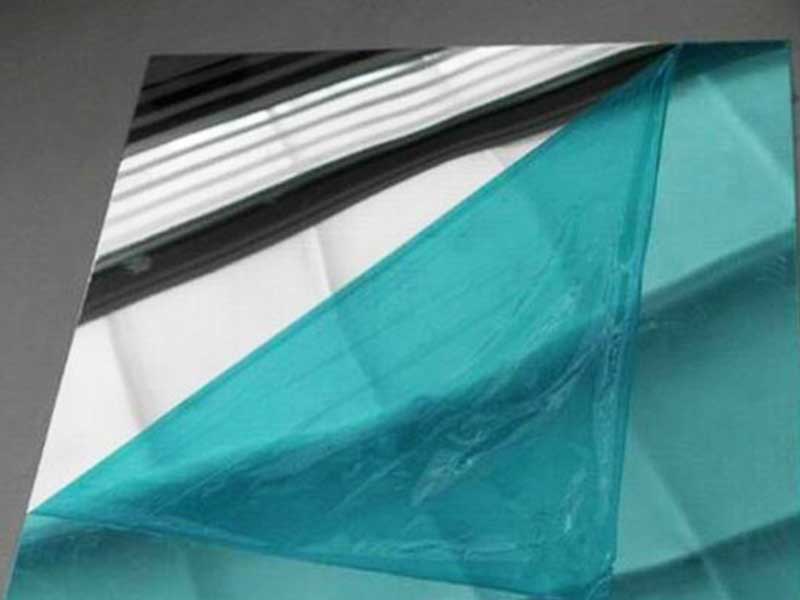

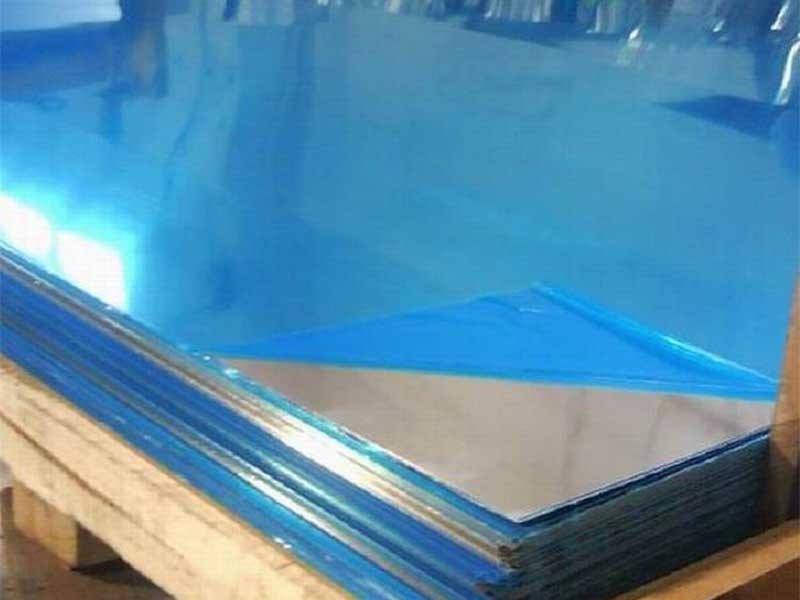

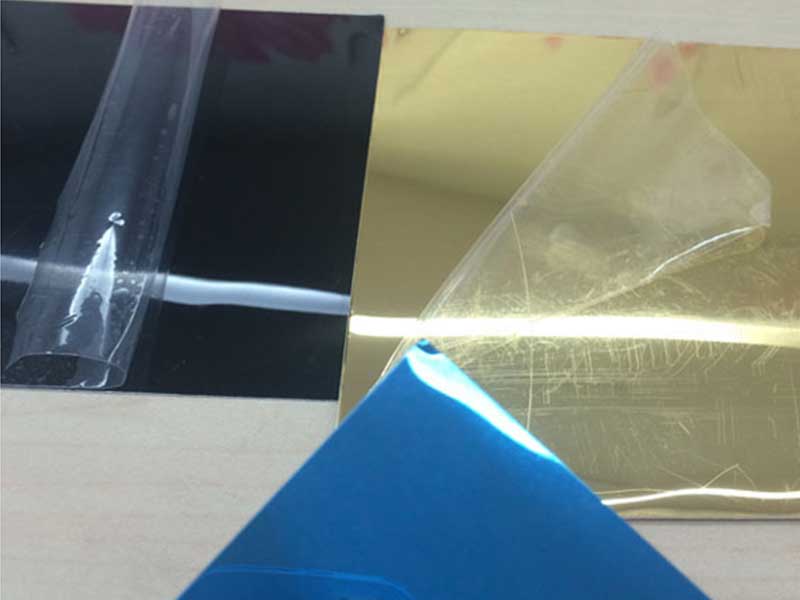

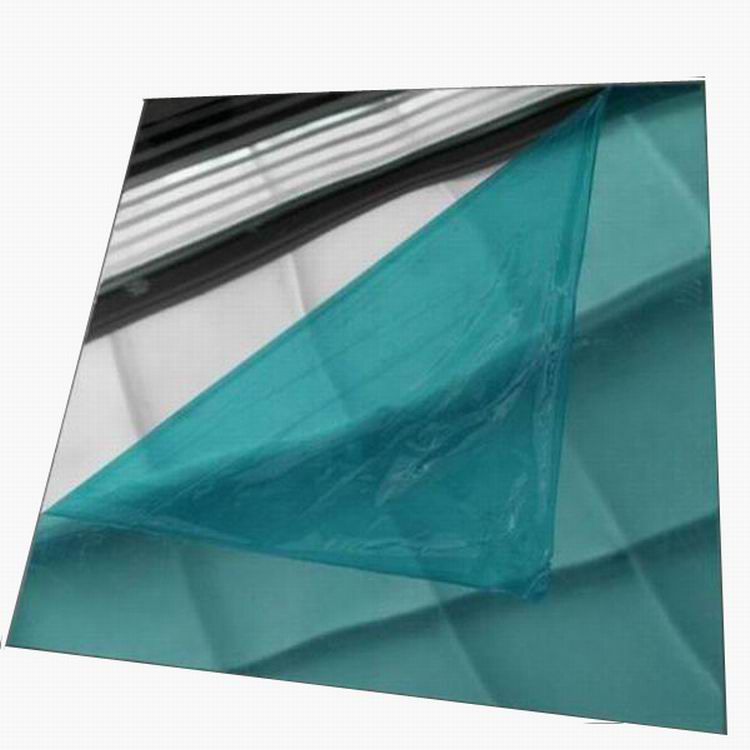

Mirrored aluminum is an aluminum sheet or plate that has undergone specialized surface treatments—primarily polishing and coating—to create a reflective, mirror-like appearance. Unlike standard aluminum sheets, these replicas have a smoothness and finish undiminished by milling marks or machining forms, delivering a distinct reflective luster often rivaling that-of glass mirrors with superior impact resistance.

Its success lies in transforming ordinary aluminum into a state comparable in looks to silvered or chromium-plated glass but far more flexible and resilient.

Alloy Composition and Chemical Properties

Typically, mirrored aluminum uses high-purity alloys to maintain surface integrity after tempering and finishing. The most common alloys include those from the 1XXX, 3XXX, and 5XXX series, prized for their corrosion resistance and ability to retain smooth finishes.

| Element | Typical Percentage Range |

|---|---|

| Aluminum (Al) | 98.5% – 99.5% |

| Silicon (Si) | 0.1 – 0.25% |

| Iron (Fe) | 0.2 – 0.5% |

| Copper (Cu) | 0.05 – 0.1% |

| Manganese (Mn) | 0.2 – 0.5% |

| Magnesium (Mg) | 0 – 0.7% (varies by alloy) |

| Zinc (Zn) | 0 – 0.1% |

| Others | Trace amounts |

These chemical characteristics enable the aluminum to gain alloy temper’s mechanical properties yet hold its intrinsic luster during stringent polishing that characterizes "mirror finish."

Alloy Tempering and Its Impact on Mirror Finish

Alloy tempering refers to the heat treatment and strain hardening profiles that aluminum undergoes to balance properties such as strength, ductility, and surface behavior.

Common designations encountered with mirrored aluminum sheets are:

- H14: Strain hardened, half hard – optimum balance, maintains shape while allowing polishing.

- H16: A touch more from H14 for tightened bending/strength.

- H18: Full hard temper providing strength, but slightly harder to polish to a mirror.

- 340 (Temper 340): Sometimes used designation for mirror-finished 5XXX series alloys, offering high corrosion resistance and good wear resistance.

Choosing the right temper fundamentally affects the surface smoothness achievable during polishing: softer tempers deform under polishing action, while very hard tempers resist polishing— thus premium mirrored aluminum balances material workability with surface reflectivity demands.

Standards and Technical Parameters

Compliance with industry standards helps guarantee mirrored aluminum meets quality benchmarks in manufacturing and usage:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate — covering thickness, strength, and surface finish benchmarks.

- ISO 4666:International standards for aluminum flat products.

- RoHS Compliance: Ensuring polished coatings and surface treatments eschew hazardous chemicals.

Technical parameters for mirrored aluminum typically include:

| Parameter | Typical Value |

|---|---|

| Thickness | 0.3 mm to 3.0 mm |

| Surface Roughness (Ra) | < 0.10 micrometer (mirror finish) |

| Reflectivity | Up to 90% or greater |

| Tensile Strength | 120 – 250 MPa (depend on alloy & temper) |

| Density | Approx. 2.7 g/cm³ |

| Corrosion Resistance | Excellent, esp. with anodizing or lacquering |

Practical Applications: Beyond the Surface Glare

The mirrored aluminum sheet is not merely decorative. Its amazingly reflective yet durable face offers broad functionality:

- Architectural façades: Metal cladding combining lightweight steel-like strength with glossy aesthetics.

- Solar reflectors: Aluminum mirrors acting as panels to concentrate solar radiation effectively.

- Transportation: On trains, buses, aircraft for lightweight reflective signage and trim.

- Interiors: Mirrors in gyms, luxury retail, or escalators blend flexibility and shatter resistance.

- Signage and Display: Functional and eye-catching surfaces resisting weather-based delamination or cracking.

Conventional glass mirrors handle many existing jobs except where weight restrictions, weather exposure, or shatter-proof safety concerns limit them. Mirrored aluminum rectifies these shortcomings, providing comparable mirror reflection in a significantly lighter, tougher, and corrosion-resistant form.