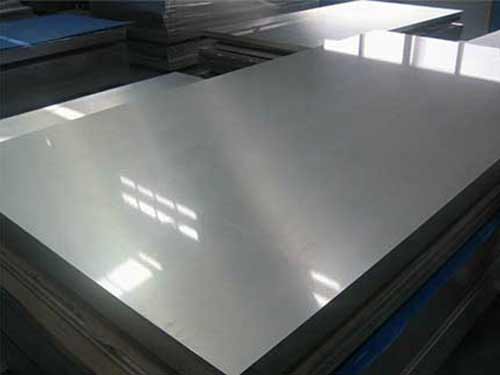

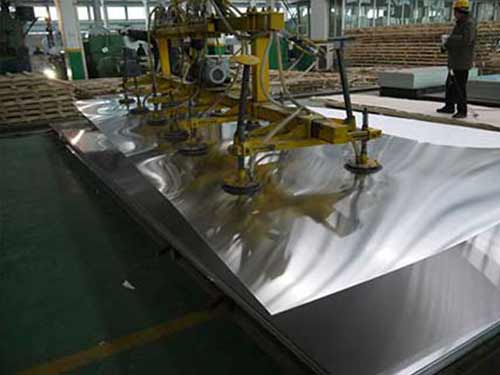

Aluminum plates have emerged as indispensable components in a diverse range of industries—spanning from aerospace and automotive to construction and electronics. aluminum plates from a technical and functional standpoint unlocks a deeper appreciation for their pivotal role in modern innovation.

The Core Functionality of Aluminum Plates

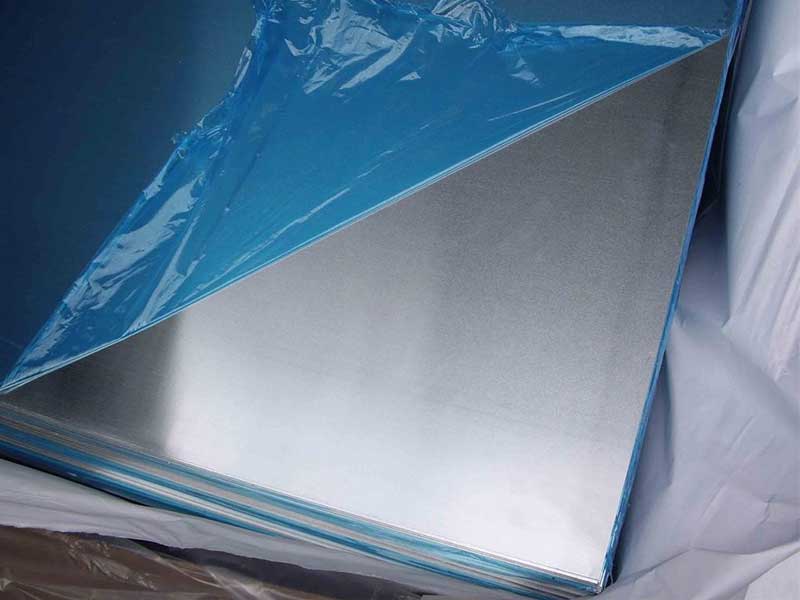

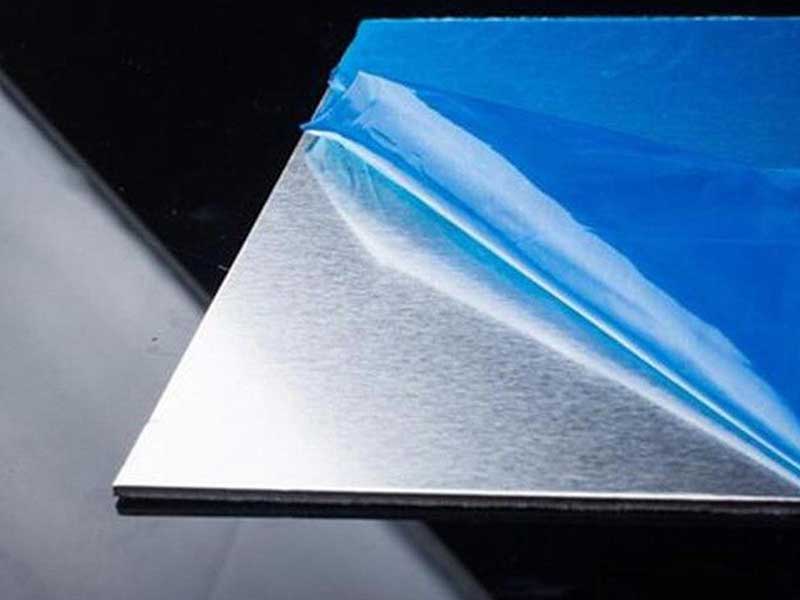

At its essence, an aluminum plate is a flat bar of aluminum alloy that boasts a thickness generally exceeding 6 mm. Unlike aluminum sheets or foils, plates are designed to provide structural integrity coupled with machinability and corrosion resistance. Their primary functions include:

- Load-bearing strength: Aluminum plates are used structurally to support heavy loads without imposing excessive weight.

- Heat conductivity: Excelling in heat dissipation, aluminum plates serve as heat sinks in electronics and automotive components.

- Corrosion resistance: Aluminum naturally forms an oxide layer that gives it excellent weather and chemical resistance.

- Machinability and weldability: Easy to work with, allowing custom shapes, slots, and precision components.

These elements combined make aluminum plates a backbone for engineering solutions requiring strength combined with lightweight material qualities.

Technical Specifications and Parameters

Dimensions

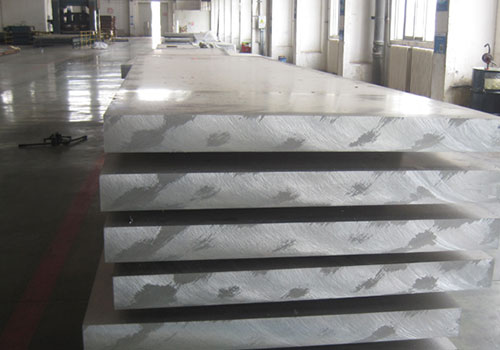

- Thickness: Typically ranges from 6 mm up to large plates measuring 200 mm or more.

- Width and Length: Customizable according to production and application needs; common widths range from 1000 mm to 2500 mm or more.

Mechanical Properties

The mechanical performance depends heavily on the alloy composition and temper, including:

| Property | Typical Range | Unit |

|---|---|---|

| Tensile Strength | 100 – 570 | MPa |

| Yield Strength | 35 – 505 | MPa |

| Elongation (%) | 5 – 12 | % |

| Hardness (HB) | 30 – 180 | Brinell |

Temper Designations

The alloy tempering significantly alters performance characteristics of aluminum plates. Common tempers include:

- O (Annealed): Softest, highest ductility, used where forming or deep drawing is needed.

- H1x (Strain-hardened, Non-heat treatable): Seal and modest strength enhancement without heat treating.

- H2x to H4x: Partial soft-to-hard conditions mainly achieved by cold working.

- T3, T4, T6 (Heat-Treated Alloys): Optimized for peak strength combined with corrosion resistance, predominantly for aerospace grades.

Export applications often require designations defined by ASTM B209, AMS, or EN standards, ensuring material uniformity and process repeatability.

Alloy Composition and Chemical Properties

Aluminum plate alloys are predominantly categorized into the 1xxx through 8xxx series based on principal alloying elements:

| Alloy Series | Base Alloy | Typical Application | Alloying Elements |

|---|---|---|---|

| 1xxx | Pure Al | Electrical, Chemical | 99%+ aluminium, minimal others |

| 2xxx | Al-Cu | Aerospace, Military | Large Cu content |

| 3xxx | Al-Mn | Architectural, Cooking | Manganese dominant |

| 5xxx | Al-Mg | Marine, Transport | Magnesium dominant |

| 6xxx | Al-Mg-Si | Structural, Auto-body | Magnesium + Silicon |

| 7xxx | Al-Zn-Mg | High-strength aerospace | Zinc + Magnesium + Copper |

| 8xxx | Misc | Specialty applications | Others (Li, Fe, etc.) |

Example: Chemical Composition of 6061 Aluminum Plate

| Element | Content (%) |

|---|---|

| Aluminum | Balance |

| Silicon | 0.4 - 0.8 |

| Iron | Up to 0.7 |

| Copper | 0.15 - 0.4 |

| Manganese | Up to 0.15 |

| Magnesium | 0.8 - 1.2 |

| Chromium | 0.04 - 0.35 |

| Zinc | Up to 0.25 |

| Titanium | Up to 0.15 |

Implementation Standards & Quality Guidelines

Ensuring the quality of aluminum plates involves conformity to global industrial standards. Important standards include:

- ASTM B209: Aluminum and aluminum-alloy sheet and plate for structural applications.

- AMS 4037/AMS 4125: Aerospace Aluminum alloy annealed and heat-treated plate.

- EN 573/EN 485: European standards on chemical composition and mechanical properties.

- ISO 6361: Aluminum sheet, strip and plate specifications.

Adhering to these standards guarantees dimensional tolerance, tensile strength, surface finish, and chemical purity essential for reliable manufacturing.

Applications Through the Lens of Material Science

Observing from a functional-material perspective uncovers why aluminum plates are everywhere today:

Aerospace: Combining strength (up to 500 MPa tensile) and low density (2.7 g/cm³), aerospace-grade aluminum plates provide vital weight savings over steel without compromising safety.

Marine engineering: The excellent corrosion resistance of 5xxx series aluminum plates extends vessel service life amid marine saltwater aggressiveness.

Automotive industry: Adoption in electric vehicle battery casings and chassis components derives from thermal conductivity and energy absorption control innate to well-tempered plates.

Heat exchange and electronics housing: These depend critically on alloys like 3003 or 6061 for efficient heat transfer and mechanical protection.

Architectural cladding: Weather, aesthetically versatile aluminum plates prove building envelope materials supported through precision alloy tempering for robustness.