Aluminum coil is one of the most versatile and essential materials in contemporary manufacturing and construction industries. It acts as a foundational raw material that feeds directly into diverse applications, ranging from building façades to automotive components, packaging solutions, and electrical products.

What Is an Aluminum Coil?

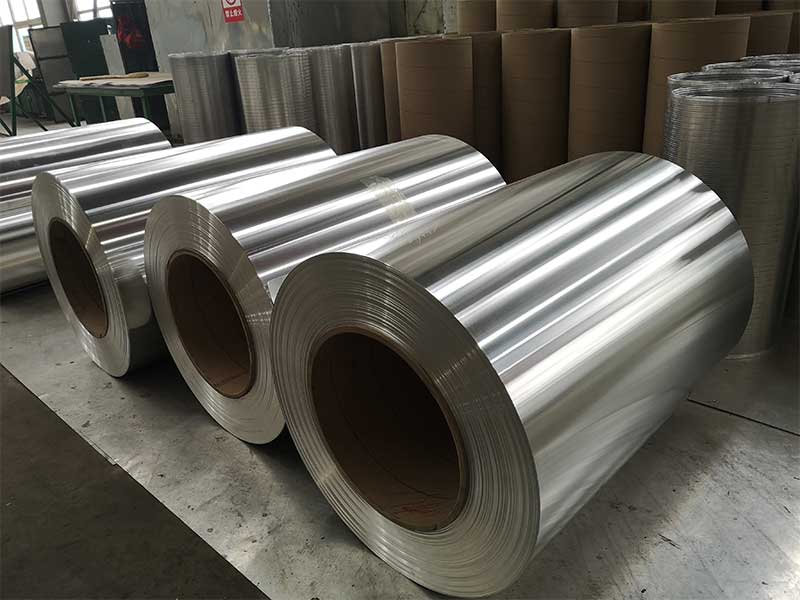

Aluminum coil is a flat-rolled product formed by feeding aluminum strips through rollers remains wound in coils. The process produces thin, uniform sheets that combine the unique properties of aluminum with ready-to-use shapes adaptable to multiple breakout industries. The sheet thickness typically ranges between 0.2 mm and 3.0 mm, while the coil width varies from 50 mm to 2000 mm or even wider depending on user requirements.

Working with aluminum coil daily gives me a unique appreciation for the material's versatility and the intricate process behind its creation. It's not just a roll of shiny metal; it's a highly engineered product with tolerances measured in thousandths of an inch. We deal with a vast range of alloys, each subtly different in its strength, workability, and intended application. A slight variation in the tempering process can significantly impact the final product's suitability for everything from automotive body panels to beverage cans. The constant hum of the rolling mill, the precise adjustments to the tension controls, and the quiet satisfaction of seeing a perfectly formed coil emerge – it's a process that inspires awe, even after years on the job.

Beyond the technical aspects, I've learned that aluminum coil production is deeply intertwined with global markets and environmental concerns. The price of aluminum fluctuates wildly, impacting production schedules and our strategic planning. Recycling plays a crucial role, not just in sustainability, but also in cost-effectiveness. We're constantly striving to improve our processes, minimizing waste and maximizing efficiency. Seeing the finished product used in everything from airplanes to building facades reminds me of the impact our work has on the world – a tangible contribution to countless industries and the everyday lives of millions.

Core Functions of Aluminum Coils

Aluminum's inherent physicochemical traits render its coils extremely valuable:

- Lightweight yet Strong: Reduced weight enhances energy efficiency, especially in aerospace and transportation.

- Broadcast Corrosion Resistance: Naturally forming oxide layers prevent rust and environmental degradation.

- Excellent Thermal and Electrical Conductivity: Crucial for heat exchangers, electrical wiring, and electronic enclosures.

- Perfect Surface Finish Compatibility: Vital for paint applications and anodizing—common on building exteriors.

- Recyclability and Sustainability: Complies with modern environmental goals due to simple recycling without quality degradation.

Chemical Composition: Fundamentally What Makes Aluminum Coils Tick

Aluminum coils conform to various implementation standards depending on manufacturing approaches, source alloys, and applications. Common industrial aluminum alloys most involved include the 1xxx, 3xxx, 5xxx, and 6xxx series:

| Alloy Series | Primary Elements | Percent Al* | Typical Features |

|---|---|---|---|

| 1xxx | >99% pure Aluminum | ≥ 99.0% | Ultra-high corrosion resistance, ductility, conductivity |

| 3xxx | Aluminum - Manganese | 94.6-96.8% | Moderate strength, good corrosion resistance, petrification resistance |

| 5xxx | Aluminum - Magnesium | 90.0-97.0% | High corrosion resistance in marine atmospheres; excellent strength |

| 6xxx | Aluminum - Magnesium & Silicon | 90-97% | Medium strength combined with excellent formability and corrosion resistance |

*Percent aluminum varies based on alloy purity and addition proportion

The alloy custom selection depends on end-use environments demanding conductivity or weather resistance or tensile strength.

Temper Designations and Their Functional Role

Product thermomechanical treatments (or cupdoor "tempers") contribute heavily to coil behavior during fabrication:

| Temper Code | Description | Functional Characteristics |

|---|---|---|

| O | Annealed (soft) | Maximum ductility; easy formability |

| H1x | Strain hardened only | Moderate strength and hardness |

| H2x | Strain hardened + partial annealed | Balance of strength and ductility |

| H3x | Strain hardened + stabilized | Stabilized mechanical properties |

| T4 | Solution heat treated + naturally aged | High strength with some ductility |

| T6 | Solution heat treated + artificially aged | Highest strength with reduced ductility |

These involve specific processes of heating, quenching, and natural/artificial aging control, critically affecting coil bending radius, stamping ability, corrosion performance, and repainting integrity in subsequent fabrication steps.

International Standards Guiding Aluminum Coil Quality

Meeting global best practices, aluminum coils abide by several standards including, but not limited to:

- ASTM B209 — covers aluminum and aluminum-alloy sheet and plate products;

- EN 485-2 — European Norm specifying test methods and mechanical property requirements;

- JIS H4000 — Japanese Industrial Standards related to aluminum coils;

- GB/T 3880 — China Standard for aluminum/magnesium alloys sheets/coils in construction;

These standards ensure strict product consistency essential for international trade and customer confidence regarding material behavior under load, thermal cycles, and exterior exposure.

Applications Leveraging Aluminum Coils’ Multifunctional Needs

- Building Industry: Aluminum coils furnish external claddings and roofs combining aesthetics with lasting weather resistance. They form rainwater harvesting systems, heat reflectors, and decorative panels.

- Automotive and Aerospace: Lightweight panels and floor decks fabricated from tempered alloy coils aggressively reduce overall vehicle mass, assisting fuel economy and speed-related performance.

- Packaging Manufacture: Aluminum packaging cores such as thin foils for medicines and food take triumph from temper-controlled ductility for wrapping and shaping.

- Cooling and Heating: HVAC coils exploit these metals due to excellent heat transfer rates alongside moderate form thinning.