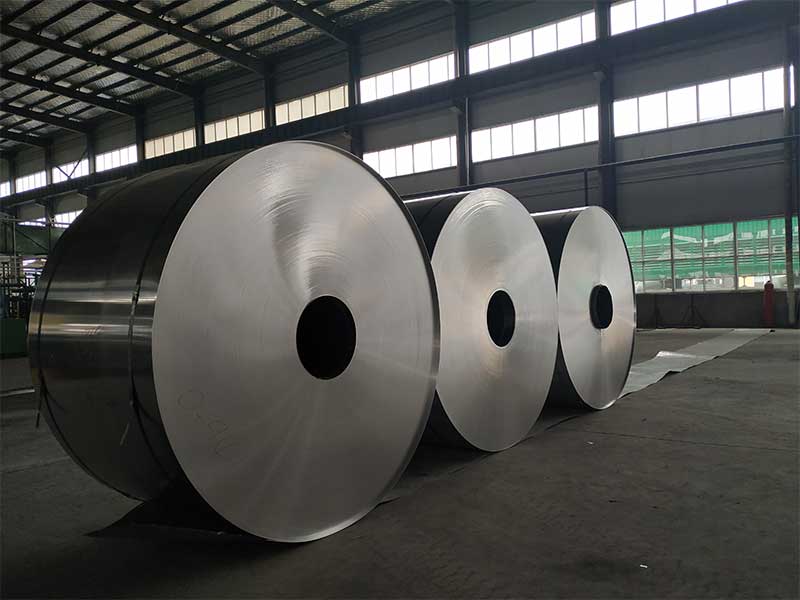

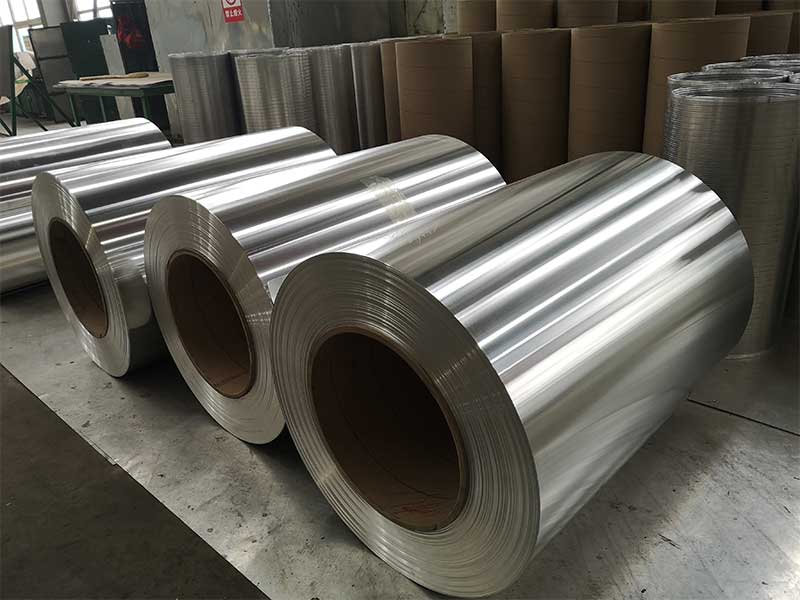

Aluminium coils have become an integral material for multiple industrial and commercial sectors. Among various thicknesses, 4mm aluminium coils is know due to their excellent balance of strength, flexibility, and functionality.

4mm aluminium coils refer to sheets of aluminium metal rolled into coil form with a thickness precisely measured at 4 millimeters. These coils combine durability, corrosion resistance, and adaptability in various manufacturing and construction fields.

Features of 4mm Aluminium Coils

| Feature | Description |

|---|---|

| Thickness | Uniform 4mm thickness, ensuring rigidity and structural strength without excessive weight. |

| Material Grade | Available in various grades such as 1100, 3003, 5052, 6061, 8011 based on industry needs. |

| Surface Finish | Options include mill finish, anodized, brushed, or coated for aesthetic and protective purposes. |

| Corrosion Resistance | Excellent corrosion resistance, particularly for grades like 3003 and 5052, suitable for harsh environments. |

| Formability | Moderate to high formability allows easy fabrication for shaping and bending. |

| Thermal & Electrical Conductivity | Aluminum coils provide outstanding thermal and electrical conductivity, useful in heat exchangers or electrical housing. |

| Lightweight | With a density approximately 2.7 g/cm³, 4mm aluminium coils offer lightness without sacrificing strength. |

Chemical Composition (Example: 3003 Aluminium Alloy)

| Element | Percentage (%) |

|---|---|

| Aluminium (Al) | Balance |

| Manganese (Mn) | 1.0 to 1.5 |

| Copper (Cu) | 0.05 max |

| Iron (Fe) | 0.7 max |

| Silicon (Si) | 0.6 max |

| Zinc (Zn) | 0.1 max |

| Others | Trace impurities |

Note: Chemical composition varies depending on the alloy type chosen.

Specifications Table of 4mm Aluminium Coils

| Parameter | Typical Values |

|---|---|

| Thickness | 4.0 mm ± 0.1 mm |

| Width | 1000mm to 2000mm (customizable) |

| Coil Weight | Up to 5,000 kg or as per requirement |

| Temper/Hardness | O, H14, H16, T6 (depending on alloy) |

| Tensile Strength | 110 to 310 MPa (varies with grade/temper) |

| Elongation at Break | 8-24% (depends on temper and alloy) |

| Density | 2.7 g/cm³ |

| Melting Point | 660°C |

Applications of 4mm Aluminium Coils

1. Construction and Architecture

The robust yet lightweight nature of 4mm aluminium coils makes them ideal for roofing sheets, curtain walls, door and window frames, and cladding panels. Its corrosion resistance particularly suits outdoor and coastal environments.

Working with 4mm aluminum coils presents a unique set of challenges compared to thinner gauges. Their substantial weight necessitates robust handling equipment; improper lifting techniques or inadequate machinery can easily lead to bending, warping, or even worker injury. Furthermore, the thicker gauge impacts processing times – shearing, slitting, and other downstream operations require more power and potentially specialized tooling to achieve clean cuts and avoid burrs or tearing. We've found that optimizing cutting parameters, specifically blade sharpness and feed rate, is crucial for maintaining consistent quality and minimizing waste with this material thickness. Preventive maintenance on our equipment is also paramount; any dulling or misalignment is magnified with 4mm coils, resulting in increased scrap and production delays.

Another consideration with 4mm aluminum coils is surface finish consistency. While the increased thickness offers greater strength and durability, it also means any imperfections in the rolling process are more pronounced. We've implemented stricter quality control measures at the incoming inspection stage, paying close attention to surface defects like scratches, pitting, and variations in thickness. This proactive approach minimizes downstream problems, particularly crucial for applications requiring a high-quality surface finish. Analyzing the coil's metallurgical properties is also valuable; inconsistencies can affect workability and final product performance, highlighting the importance of sourcing from reputable suppliers with robust quality management systems.

2. Automotive Industry

Heavy-duty automotive components such as body panels, chassis parts, and heat shields utilize 4mm aluminium coils, optimizing vehicle performance by reducing weight while enhancing fuel efficiency and corrosion resistance.

3. HVAC Systems

The excellent thermal conductivity and formability enable 4mm aluminium coils to be used in heat exchangers, air conditioning ducts, and ventilation systems, facilitating efficient heat and airflow management.

4. Packaging

Thicker aluminium coils assist in manufacturing durable packaging materials that require additional rigidity, like aerosol cans and specialized containers.

5. Electrical Applications

Due to the high electrical conductivity and resistance to corrosion, these coils fit well in electrical housings, enclosures, and cable applications.

Why Choose 4mm Aluminium Coils From Us?

- Premium Quality: Sourced from the finest raw materials and subjected to rigorous QC processes.

- Tailored Coils: Customize width, temper, and finish according to your production line needs.

- Technical Support: Professional advisory from selection to after-sales.

- Prompt Delivery: Efficient supply chain ensuring on-time delivery globally.