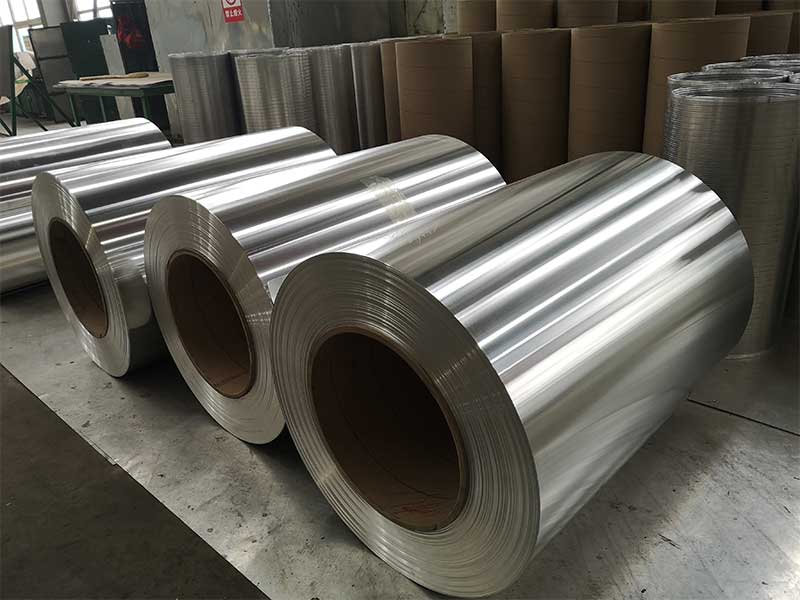

Aluminum coils are integral to many industries, particularly when specific mechanical properties and resilience are required without compromising material weight. Among the various aluminum alloys, Aluminum Coil 1mm Thick 5052 in H34 and H32 tempers stands out as a highly versatile and functional product known for its excellent durability and wide application range.

Aluminum 5052 alloy is primarily composed of magnesium (Mg), which enhances its corrosion resistance, formability, and strength compared to pure aluminum. The 1mm thickness is a popular dimension offering flexibility for forming and structural use, while ensuring enough rigidity and surface integrity.

The tempers H34 and H32 refer to different hardening processes that balance strength and ductility for distinct needs:

- H34 temper: Strain-hardened and partially annealed for medium hardness

- H32 temper: Strain-hardened and stabilized with less hardening than H34 (half hard)

These tempers influence fatigue strength, bending capabilities, and wear resistance.

Technical Specifications and Parameters

| Parameter | Specification | Details |

|---|---|---|

| Alloy | 5052 | Magnesium-based aluminum alloy |

| Thickness | 1.0 mm | Standard thickness for formability |

| Temper Condition | H34, H32 | H34 offers higher strength; H32 for moderate proof stress |

| Tensile Strength | H34: ~235-275 MPa; H32: ~180-220 MPa | Ultimate tensile strength |

| Yield Strength | H34: ~160-210 MPa; H32: ~130-180 MPa | Offset yield strength (0.2% proof) |

| Elongation at break | H34: 7-12%; H32: 15-20% | Extensibility measure before failure |

| Density | 2.68 g/cm³ | Standard density for aluminum |

| Thermal Conductivity | ~138 W/m·K | Efficient heat dissipation |

| Melting Point | 607–650°C | Alloy-specific melting range |

Chemical Composition

Adherence to established standards such as ASTM B209 and AMS-QQ-A-250 ensures uniformity and ideal performance characteristics.

Working with 5052 H34 and H32 aluminum coil at 1mm thickness presents a unique set of challenges and advantages. The 5052 alloy itself is prized for its excellent corrosion resistance, making it ideal for applications demanding longevity outdoors or in harsh environments. However, at 1mm, the material is relatively thin and requires careful handling during processing to avoid scratching, denting, or even tearing. We frequently see issues with edge burring during slitting, necessitating extra attention to our machinery's maintenance and the use of specialized tooling. The H34 temper, being slightly softer than the H32, allows for easier forming but requires more consideration during storage to prevent warping or bowing. We've found that optimal stacking and palletizing are crucial to maintain flatness.

The difference between H34 and H32 tempers is subtle yet impactful. While both are suitable for a wide range of applications, the slightly harder H32 offers better dimensional stability, especially important in situations where precise tolerances are critical, like automotive parts or certain types of construction materials. We see a higher demand for the H32 due to this enhanced stability, but the H34's malleability keeps it consistently popular for applications involving more complex forming processes. these nuances, along with the inherent challenges of working with thin gauge aluminum, has been to our team's success in consistently delivering high

| element | Min (%) | Max (%) |

|---|---|---|

| Aluminum (Al) | Bal | Bal |

| Magnesium (Mg) | 2.2 | 2.8 |

| Chromium (Cr) | 0.15 | 0.35 |

| Manganese (Mn) | 0.10 | 0.40 |

| Iron (Fe) | – | 0.40 |

| Copper (Cu) | – | 0.10 |

| Silicon (Si) | – | 0.25 |

| Zinc (Zn) | – | 0.10 |

| Titanium (Ti) | – | 0.03 |

Alloy Tempering and Mechanical Behavior

H34 Temper: Produced by strain hardening from the H18 condition, followed by partial annealing to relieve stresses while preserving significant hardness and strength. This makes 5052 H34 coils suitable for parts requiring rigidity combined with modest forming ability, such as marine vessels, fuel tanks, and automotive panels.

H32 Temper: Achieved through strain hardening stabilized at intermediate levels to maintain good ductility alongside moderate hardness. H32 5052 aluminum coils are ideal for curved automotive body parts, architectural panels, and other shapes where medium formability is necessary while maintaining resistance to deformation.

Application Insights: Where Aluminum Coil 1mm 5052 Shines

Marine Industry: Due to excellent corrosion resistance in saltwater, 5052 coil is often used in boat hulls, decks, and offshore platforms where exposure to harsh environments demands both lightweight and durable solutions.

Automotive and Transportation: Thin yet tough, the 1mm 5052 H34/H32 coils are utilized for truck fuel tanks, transport vehicle panels, reinforcing materials, and protective covering, enhancing fuel efficiency by reducing weight without compromising safety.

Architecture and Construction: Weather-resistant qualities and aesthetic surface finish make these coils perfect for windows, roofing, and exterior cladding, particularly in humid or corrosive urban environments.

Electrical and Electronics: Its excellent thermal conductivity supports heat dissipation in enclosures, heat sinks, and electromagnetic shielding where thin, uniform thickness aluminum is required.

Food Processing and Chemical Industries: Noted for being non-toxic, corrosion-resistant, and hygienic for food and chemical equipment lined with aluminum coil sheets.

Implementation Standards and Quality Assurance

Products meet or exceed performance and chemical property benchmarks defined by international standards:

- ASTM B209 (Aluminum and Aluminum-Alloy Sheet and Plate)

- AMS-QQ-A-250 Rev D

- EN 573-3 Dimension and composition criteria

They undergo rigorous testing for strength, flexibility, corrosion resistance, and surface treatment compatibility — ensuring optimal performance in both structural and decorative applications.

The balance of strength, corrosion resistance, and formability allows manufacturers across sectors to capitalize on 1mm thick 5052 aluminum coils in H34 and H32 conditions for innovative and efficient designs. From marine environments demanding durability to automotive weight reduction strategies, or architectural visual appeal — these coils deliver consistent quality and versatility.

In conclusion, selecting 5052 aluminum coils at 1mm thickness combines proven alloy chemistry and tailored mechanical tempering to fuel progress across modern industries. When durability meets adaptability, the 5052 H34 and H32 aluminum coil is plainly unmatched.

Your trusted partner in aluminum innovation — explore the exceptional world of 5052 Aluminum Coils tailored for your specific industry needs today!