Aluminum sheet plate metal occupies an unparalleled position in the metals industry due to its exceptional combination of light weight, durability, and versatility. From aerospace frames to automotive chassis, from architectural cladding to food packaging, aluminum’s role is expansive. However, aluminum sheet plate metal from a functional and technical perspective reveals why it serves such a broad spectrum of industries with increasing precision.

Functional Insights: Why Aluminum Sheet Plate Metal?

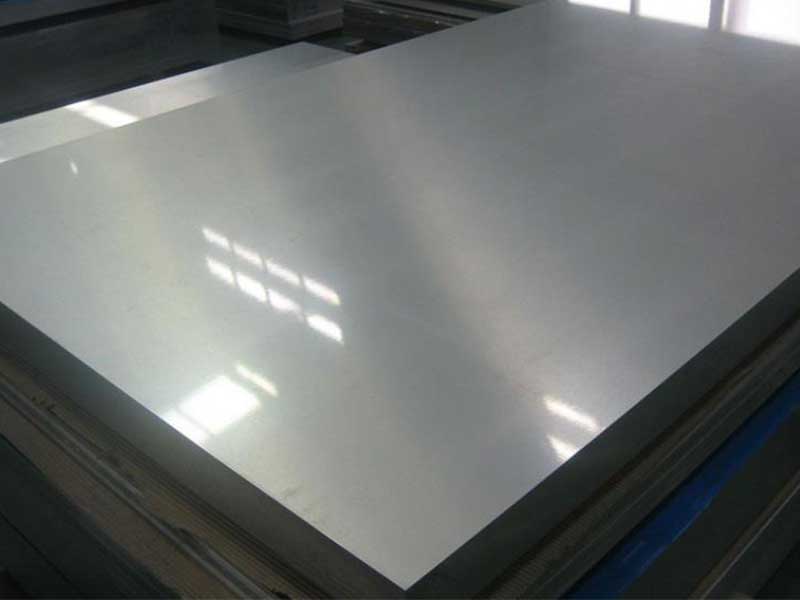

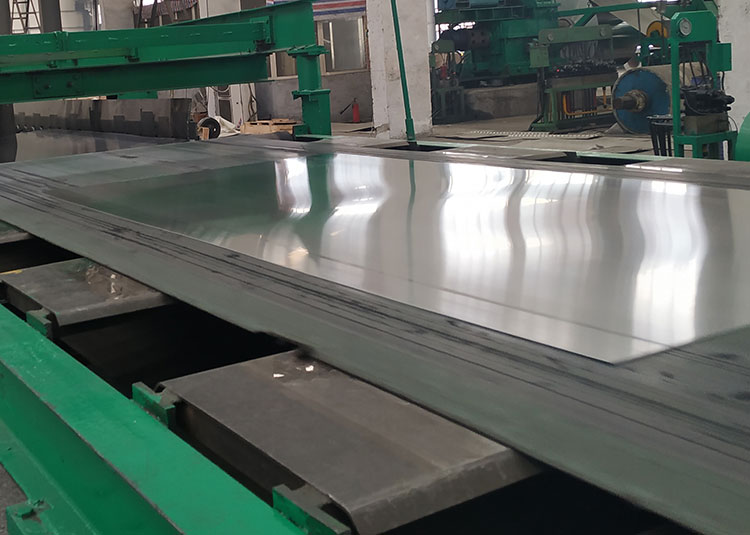

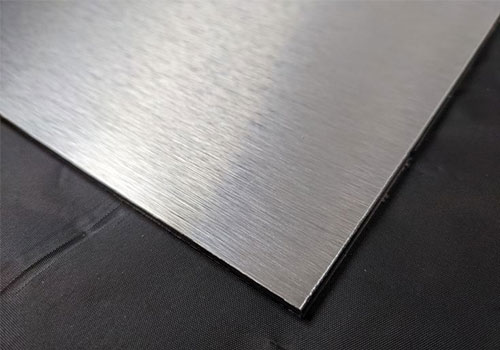

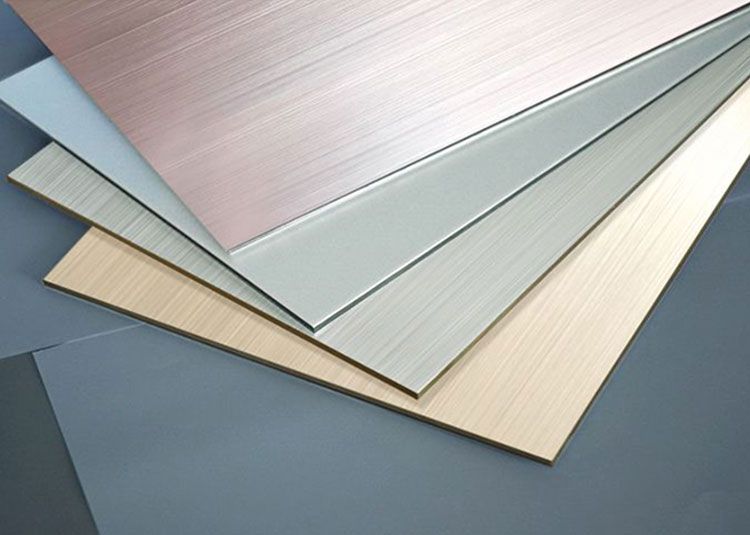

Unlike raw aluminum or other forms of aluminum products, aluminum sheet plate metal refers to flat-rolled metal that varies in thickness to produce both sheets (generally thinner than 6 mm) and plates (thicker upwards of 6 mm). This seemingly simple dimension difference impacts functionality significantly:

- Structural Integrity & Load Bearing: Aluminum plates find frequent use in components requiring high mechanical strength and fracture toughness. Their thickness makes them indispensable in aerospace bulkheads or ship hull parts.

- Flexibility & Forming Capability: Aluminum sheets excel where flexibility, shaping, or stamping is paramount, such as in automotive body panels and HVAC (Heating, Ventilation, and Air Conditioning) ducts.

- Surface Finish: Surface preparation (e.g., anodizing or cladding) is easier on sheet form, facilitating use in decorative or corrosion-resistant applications such as architectural facades and household appliances.

Each function steers the specific alloy selection and the tempering or work-hardening processes, defining the balance between hardness, ductility, and corrosion resistance.

Resolving the Technical Fabric: Alloys, Temper, and Implementation Standards

Aluminum sheet and plate metals come in diverse alloys and tempers standardized under ASTM, AMS, ISO, and other internationally recognized protocols. these practices enables buying and working with products meticulously engineered for the intended environment.

Common Alloy Families and Typical Chemical Composition

| Alloy Series | Principal Elements | Typical Use Examples |

|---|---|---|

| 1xxx | ≥ 99% Al (High purity) | Electrical components, chemical equipment |

| 2xxx | Al-Cu (Copper 2-6%) | Aerospace structures, military grade |

| 3xxx | Al-Mn (Manganese 1-1.5%) | Roofing, siding, cooking utensils |

| 4xxx | Al-Si (Silicon 4-13%) | Automotive parts, furnace components |

| 5xxx | Al-Mg (Magnesium 2.5-5%) | Marine environments, automotive panels |

| 6xxx | Al-Mg-Si (Magnesium + Silicon) | Structural and architectural applications |

| 7xxx | Al-Zn-Mg-Cu (High strength alloy) | Aerospace, sports equipment |

The CSV-equivalent example of a chemical composition for a typical 6061 aluminum sheet plate is presented here:

| Element | Weight % Range |

|---|---|

| Al | Balance |

| Mg | 0.8 – 1.2 |

| Si | 0.4 – 0.8 |

| Cu | 0.15 – 0.4 |

| Cr | 0.04 – 0.35 |

| Fe | ≤ 0.7 |

Temper Designations

The temper of the aluminum sheet plate—a designation like T6, T651, H14—signals its thermal and mechanical processing to achieve required hardness and ductility levels:

- O (Annealed): Soft condition, max ductility.

- H1x (Strain Hardened): Means cooled from elevated temperature shaping (e.g., H14 indicates strain hardened to 1/2 hardness).

- T6 (Solution Heat-Treated and Artificially Aged): Used for maximum strength trade-off.

- T651 (Stress Relieved T6): Structural applications needing reduced residual stress.

A 6xxx series aluminum plate in temper T6 strikes a useful shape-memory and load resilience balance for engineering applications like frames and molds.

Critical Industry Standards

Executors and fabricators of aluminum sheet plate metal usually consult these critical norms:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- AMS 4045: Aerospace material standards

- ISO 6361: Drawing and Rolling Quality Aluminum Sheet

- Various certifications outline permissible dimensional tolerances, surface finishes, chemical makeup, and mechanical properties (e.g., tensile strength, yield strength).

Application Spectrum Explored Through a Functional Lens

Aerospace and Defense: Load-bearing, lightweight aluminum plates made from 2xxx and 7xxx series alloys are engineered to strict standards allowing them to endure extreme stresses while minimizing aircraft weight. Strength-tailored tempers (T6, T651) impart essential stiffness without sacrificing fatigue resistance.

Automotive & Transportation: The switch to aluminum sheets in 5xxx and 6xxx series with optimized electrocoating synthetic wraps reduces vehicle weight to improve fuel efficiency. Aluminum’s corrosion resistance aligns perfectly with exterior panel applications.

Marine Engineering: Highly corrosion-resistant 5xxx series Aluminum plates resist the erosive seawater while offering weldability necessary for shipbuilding and dockyard structures.

Food and Beverage Sector: Ultra-pure 1xxxseries aluminum sheets with near 99.9% purity contribute to hygienic, inert packaging, reflecting aluminum’s effective chemical inertness.

Construction & Electronics: Aluminum sheet plate metal furnishes durable surface facades coupled with thermal conductivity for heat sinks and casings.