In the ever-demanding sphere of marine frame engineering, material selection can be the decisive factor between durability and early structural failure. Among various options, 6082 marine aluminum hollow bars have emerged as a favored choice, blending superior strength, corrosion resistance, and ease of fabrication.

Why Choose 6082 Aluminum for Marine Frames?

Marine frames require a material that can withstand aggressive saline environments, heavy mechanical loads, and relentless impact forces from waves and onboard activity. The alloy 6082, a medium-strength alloy in the 6xxx series (Al-Mg-Si), features an optimal balance of mechanical performance and corrosion resistance, making it quintessential for such applications.

Working with 6082 marine aluminum hollow bars in our marine frame engineering projects is a constant balancing act between strength, weight, and cost. We often see designs that initially overspecify the material, leading to unnecessary expense. My experience shows that a thorough Finite Element Analysis (FEA) is crucial before finalizing a design. This allows us to optimize the wall thickness of the hollow bar, reducing weight without sacrificing structural integrity. We've also learned the importance of proper surface treatment – anodizing is essential for corrosion resistance, especially in saltwater environments. Getting that process just right is vital to the longevity of the final product, and we've invested heavily in quality control to ensure it.

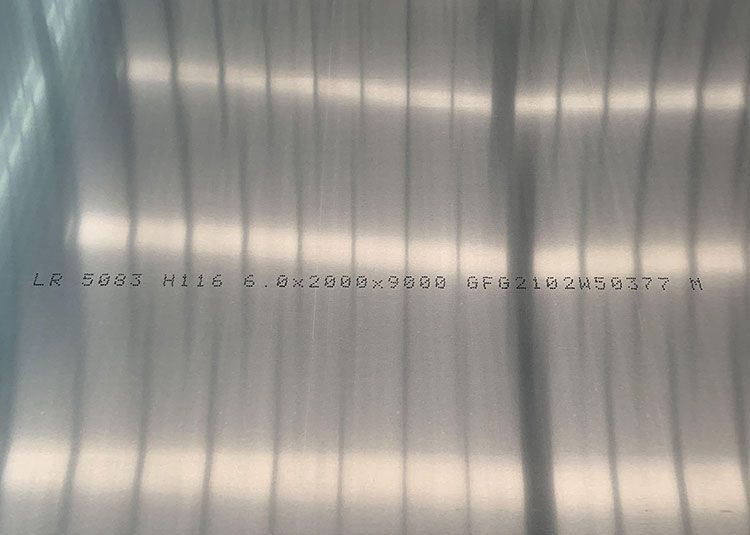

Beyond the technical aspects, a unique challenge with 6082 hollow bars is sourcing consistent, high-quality material. We've unfortunately seen variations in the alloy's composition from different suppliers, leading to unpredictable mechanical properties. This highlights the importance of building strong relationships with reliable suppliers and meticulously tracking batch numbers for every project. Furthermore, working with hollow bars adds a layer of complexity to fabrication, requiring specialized machining techniques to avoid damage to the tube's integrity. We've developed internal best practices and training programs to mitigate this risk and ensure our technicians possess the necessary expertise for precise and efficient processing.

The hollow bar design ingeniously reduces overall frame weight without compromising structural integrity. By using hollow bars instead of solid sections, engineers reduce weight, thereby enhancing vessel maneuverability and fuel efficiency without undermining frame rigidity.

Fundamental Properties and Mechanical Parameters of 6082 Marine Aluminum Hollow Bars

| Property | Specification |

|---|---|

| Chemical Composition (%) | |

| Silicon (Si) | 0.7 – 1.3 |

| Magnesium (Mg) | 0.6 – 1.2 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.5 |

| Copper (Cu) | ≤ 0.1 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.1 |

| Aluminum (Al) | Balance |

| Mechanical Property | 6082-T6 Temper Solution |

|---|---|

| Tensile Strength (MPa) | ≥ 310 |

| Yield Strength (MPa) | ≥ 260 |

| Elongation (%) | ≥ 8 |

| Hardness (HB) | 95 – 115 |

| Density (g/cm³) | 2.70 |

Implementation Standards and Alloy Temper Conditions

Marine aluminum hollow bars crafted from 6082 aluminum typically follow stringent guidelines such as ISO 6361 and ASTM B221 for extrusion products in marine applications. Also, depending on the specific engineering demands, temper conditions like T6 (solution heat-treated and artificially aged) or T651 (solution heat-treated, stress-relieved via stretching, and then artificially aged) are regularly applied to enhance mechanical strength and resistance against stress corrosion cracking.

- T6 Temper: Most common for marine frames, offering peak strength and a firm, hard surface.

- T651 Temper: Used when additional dimensional stability is required after heat treatment.

Notably, the presence of manganese and magnesium enhances corrosion resistance specifically in saltwater marine environments. This, paired with proper anodization treatments or protective coatings, considerably boosts lifespan.

Practical Advantages in Marine Engineering

Weight Reduction: Hollow profiles reduce overall mass enabling easier assembly and improved fuel efficiency.

Corrosion Resistance: Superior intrinsic resistance eliminates the frequent need for costly maintenance cycles typical with steels.

Ease of Welding and Fabrication: 6082 alloys have excellent extrusion characteristics making hollow bars easier to manufacture in complex, custom geometries suited for robust frame members.

Strength and Toughness: A tensile strength upwards of 310 MPa assures marine frames can handle wave-induced stress and onboard dynamic loads reliably.

Chemical Reaction & Maintenance Insights

While marine grade alloys brag of superior decomposition resistance in saltwater environments, regular inspection for pitting or intergranular corrosion is advisable. Protective coatings and sacrificial anodes can be incorporated in marine frames made with 6082 hollow bars for enhanced lifespan.