Efficient thermal management is a cornerstone for the optimal performance and longevity of marine engines. One of the vital components in this ecosystem is the Marine Aluminum Heat Sink Profile, designed specifically to dissipate heat in harsh marine environments. Unlike conventional aluminum profiles, marine-grade alloys offer superior corrosion resistance, high thermal conductivity, and mechanical strength—making them indispensable in critical cooling applications on marine vessels.

Why Choose Marine Aluminum for Heat Sink Profiles?

Marine aluminum, commonly derived from aluminum alloy series 5000 and 6000, exhibits a unique balance of corrosion resistance and tensile strength, essential for marine environments where saltwater and humidity accelerate material degradation. The 5xxx series (Al-Mg alloys), particularly 5083 and 5052, are frequently preferred for marine heat sinks due to:

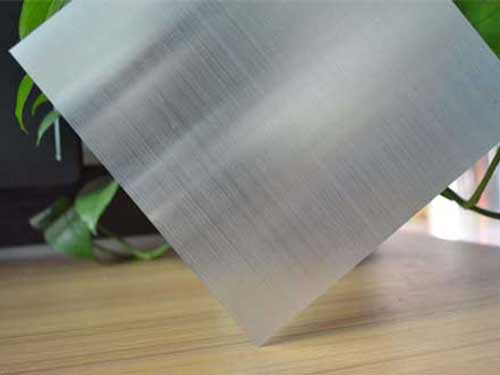

Marine aluminum heat sinks present unique challenges compared to their terrestrial counterparts. The harsh marine environment introduces corrosive saltwater spray, intense UV radiation, and fluctuating temperatures, demanding materials with exceptional corrosion resistance and thermal performance. In my experience, simply specifying a high-purity aluminum alloy isn't sufficient. We've found that incorporating surface treatments like anodizing, powder coating, or even electroless nickel plating significantly extends the lifespan of the heat sink, preventing pitting and galvanic corrosion. Furthermore, the design itself is critical; we've experimented with fin geometries to optimize airflow in the often-confined engine compartments of vessels, focusing on maximizing surface area while maintaining structural integrity against vibration and impacts common in marine applications.

Beyond material selection and design, the specific thermal characteristics of the engine is crucial. Different engine types (diesel, gasoline, etc.) generate varying amounts of heat and have unique temperature profiles. We've seen instances where a seemingly adequate heat sink fails due to an insufficient of the engine's heat dissipation requirements. Therefore, close collaboration with engine manufacturers is paramount. Thermal modeling and rigorous testing, including salt spray and thermal cycling tests simulating real-world marine conditions, are essential to ensure the heat sink performs reliably and prevents overheating, ultimately contributing to engine longevity and preventing costly downtime.

- Excellent resistance to saltwater corrosion

- Good weldability

- Robust mechanical properties even at low temperatures

On the other hand, 6xxx series alloys (Al-Mg-Si alloys) such as 6061 are favored in profiles requiring enhanced rigidity and uniform extrusion capabilities.

To achieve an efficient thermal gradient, the heat sink profile’s design parameters typically adhere to both mechanical and thermodynamic principles:

| Parameter | Typical Range / Value | Notes |

|---|---|---|

| Alloy composition | 5083-H111, 6061-T6 | Common standards used |

| Thermal conductivity | 120-160 W/m·K | Depends on exact alloy and temper condition |

| Tensile strength | 210-310 MPa | Alloy and temper dependent |

| Corrosion resistance | Excellent | Saltwater durability per ASTM B117 standards |

| Density | ~2.66 g/cm³ | Lightweight compared to steel |

| Surface treatment | Anodization or chemical conversion | Enhance corrosion resistance and emissivity |

| Heat capacity | ~0.9 J/g·K | Contributes to heat absorption |

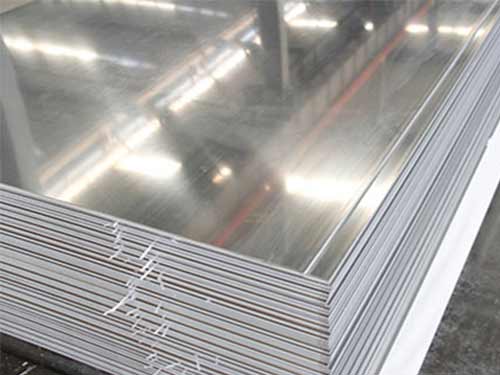

Alloy Tempering and Implementation Standards

Marine aluminum heat sink profiles often undergo specific temper relaxing and strengthening processes that optimize the mechanical and thermal characteristics:

- H111 Temper for 5083 alloys retains good strength with superior ductility, advantageous for extrusion into complex heat sink geometries.

- T6 Temper for 6061 means solution heat-treated and artificially aged for maximum strength, ideal for applications needing tighter dimensional control and high rigidity.

Fabrication and Implementation Standards:

- ASTM B221: Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes governing quality and geometric tolerances of the extruded profiles.

- ISO 9227: Accelerated salt spray corrosion testing ensures profiles withstand harsh marine environments.

- MIL-DTL-24779: For military-grade marine aluminum profiles requiring enhanced mechanical and environmental properties.

Chemical Composition Table of Typical Marine Aluminum Alloys

| Element | 5083 Alloy (%) | 5052 Alloy (%) | 6061 Alloy (%) |

|---|---|---|---|

| Aluminum (Al) | Balance | Balance | Balance |

| Magnesium (Mg) | 4.0 – 4.9 | 2.2 – 2.8 | 0.8 – 1.2 |

| Manganese (Mn) | 0.4 – 1.0 | 0.1 | 0.15 |

| Silicon (Si) | 0.4 Max | 0.25 Max | 0.4 – 0.8 |

| Iron (Fe) | 0.4 Max | 0.4 Max | 0.7 Max |

| Chromium (Cr) | 0.05 – 0.25 | 0.15 – 0.35 | 0.04 – 0.35 |

| Copper (Cu) | 0.1 Max | 0.1 Max | 0.15 – 0.4 |

| Zinc (Zn) | 0.25 Max | 0.2 Max | 0.25 Max |

| Titanium (Ti) | 0.05 – 0.15 | 0.01 – 0.2 | 0.15 Max |

Practical Considerations in Marine Heat Sink Profile Design

1. Corrosion Protection Strategies

Aluminum’s inherent oxide layer provides moderate corrosion resistance; yet, in continuous submersion or splashing conditions, implementing anodizing or chromate conversion coatings drastically improves service life.

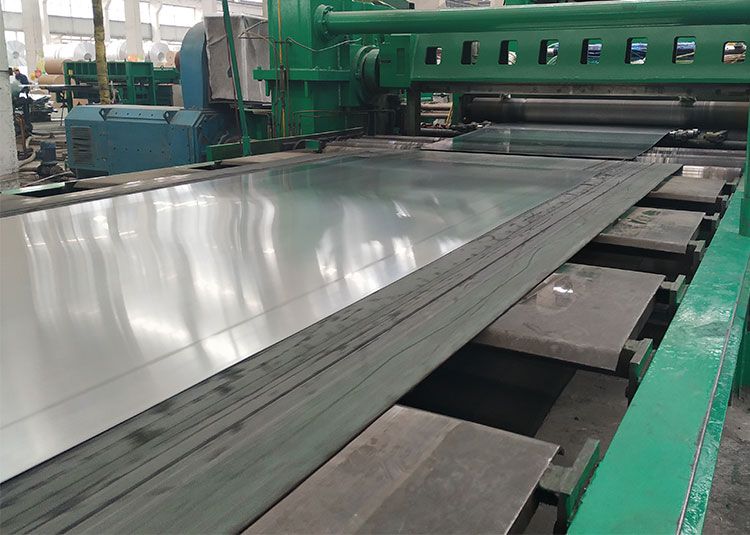

2. Extrusion Precision & Profile Geometry

Innovative extrusion technology ensures precise heat sink fins and cavities tailored for maximizing convective heat transfer while considering coolant accessibility within the marine engine cooling systems.

3. Thermal Efficiency & Structural Rigidity

To bolster uniform heat dissipation, proprietary marine aluminum profiles sometimes integrate tubular or folded fin concepts balancing the surface area with structural integrity demanded by marine engine vibrations.