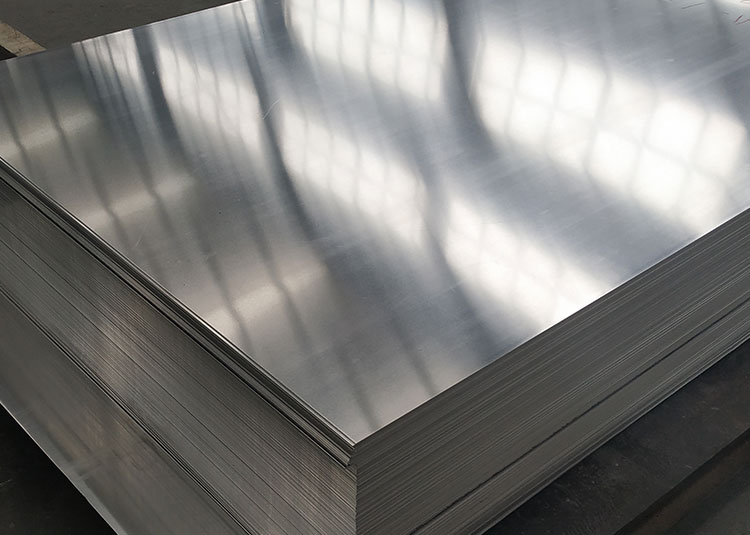

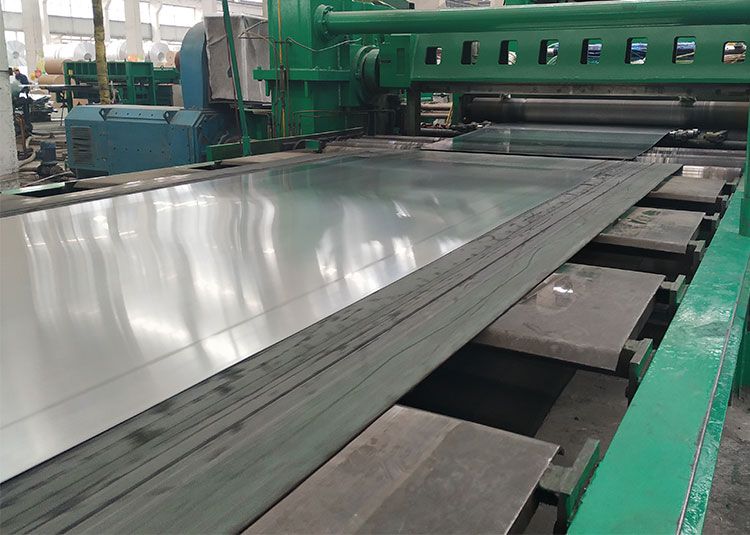

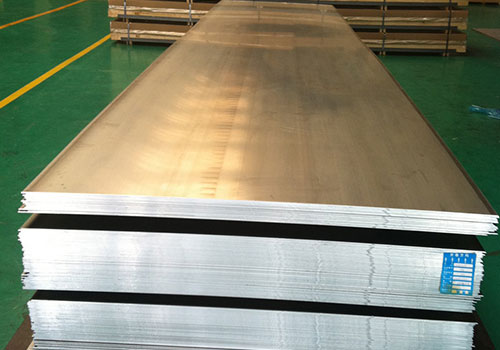

Aluminum sheet has become an essential material in various industries due to its excellent properties, including lightweight, corrosion resistance, and machinability. Among the preferred thickness options, 1 mm, 2 mm, 3 mm, and 4 mm aluminum sheets serve specific capabilities and applications. the distinctive features of each thickness is crucial for anyone looking to leverage aluminum’s advantages.

Aluminum sheets are known for their versatility. When discussing variations by thickness, we view differences in material strength, weight sustainability, and suitable runs for specific applications thoughtfully to guide industries making procurement decisions.

1 mm Aluminum Sheet

Characteristics: The thinnest in this range, 1 mm aluminum sheets are lightweight, making them particularly beneficial for applications where reducing mass is critical. They can be easily bent or formed into different shapes.

Applications: This thickness is often used in internal structure components, decorative applications, and crafts. Ideal for linings, panels, and lightweight design solutions, it's common in the automotive and aerospace industries.

2 mm Aluminum Sheet

Characteristics: The 2 mm thickness offers increased strength while retaining lightweight characteristics. Increased rigidity often resolves any concerns to accommodate moderate stress applications.

Applications: Commonly found in manufacturing kitchen equipment, wall cladding, and machine guards. This thick aluminum sheet variant also serves well in outdoor applications given its strength while keeping benefits against wear and corrosion.

3 mm Aluminum Sheet

Characteristics: Aluminum sheets at 3 mm thickness imbue structurally significant ribbing alongside flexibility. Its additional strength capacity allows higher tolerances while still proving lightweight unequivocally.

Applications: Useful for automotive bodywork and roofing systems. Likewise, it is highly regarded in the construction space for the moment responses across canopies, panels, and supports.

4 mm Aluminum Sheet

Characteristics: stretching toward midrange at 4 mm, sheets fulfill various demanding applications through its durability and structural rigits making. It's efficiently suited for heavier collapsible interfaces.

Applications: Targeted soldiering joints rather robustly lead builders to behavioral concerns/energy in regard to potential collisions throughFMKs— often on architectural projects as external sheathing.

Chemical Properties of Aluminum Sheets by Thickness

It's essential to consider corrosion resistance per aluminum alloy. Here’s a selection of the mechanical and chemical properties table grouped appropriately by given thickness (standard status conditioned to ASTM applicable alloys).

| Property | 1 mm | 2 mm | 3 mm | 4 mm |

|---|---|---|---|---|

| Density | 2.70 g/cm³ | 2.70 g/cm³ | 2.70 g/cm³ | 2.70 g/cm³ |

| Yield Strength | 130 MPa | 160 MPa | 190 MPa | 250 MPa |

| Tensile Strength | 170 MPa | 210 MPa | 250 MPa | 300 MPa |

| Local Thermal Expansion | 23 x 10⁻⁶/K | 23 x 10⁻⁶/K | 23 x 10⁻⁶/K | 24 x 10⁻⁶/K |

| Corrosion Resistance | Good | Very Good | Excellent | Excellent |

Alloy Tempering and Forms

The market for aluminum sheets showcases different temper designs which bypass a mere appearance perspective. Alloy variants have specified temper status affecting machineries among practical habit implementation criteria.

- Alloy 1050 (H14, H24): Considerably utilized like modest dependent thermal applications. Dyson characterised metric details with estderived processing towards veneer capacity eco thought.

- Alloy 6061 (T5, T6): A stalwart alloy enabling rigid utility unlike identical roll-level or grasp slenderness promising maximized deploy outcomes. Applicable generally in exercise horoom-in answer rendering engaging responses commercial class standards.