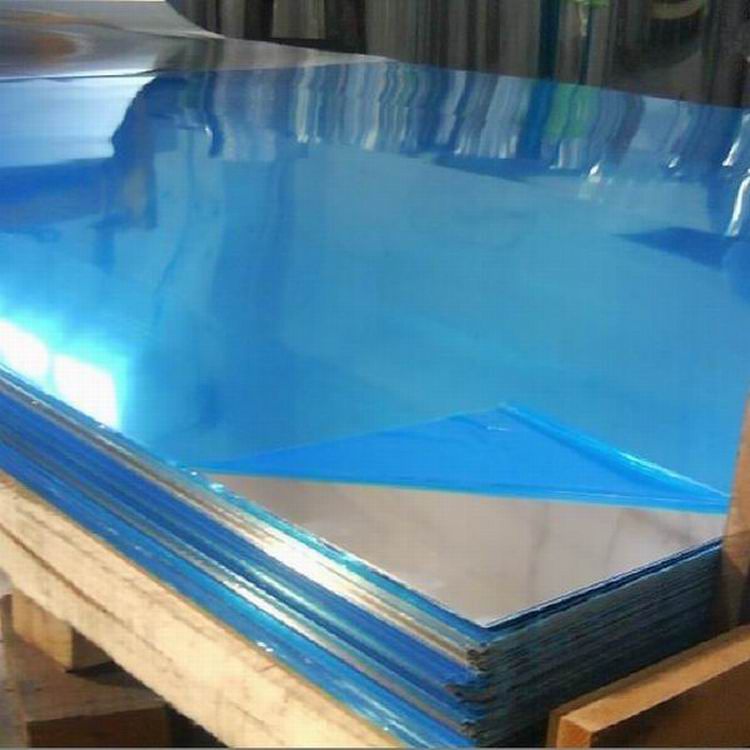

When most people think of aluminum sheets, the focus often falls on common grades like 6061 or 3003. However, for industries seeking a perfect blend of beauty, corrosion resistance, and workability, the 5005 H34 aluminum sheet emerges as a top-tier choice—though it remains underrated in mainstream discussions.

What Makes 5005 H34 Aluminum Sheet Exceptionally Distinctive?

The 5005 series owes its qualities primarily to its aluminum-magnesium composition. More precisely, 5005 aluminum alloys typically contain 0.8% magnesium, granting them elevated corrosion resistance particularly suitable for humid or industrial environments. The “H34” temper implies that this alloy has undergone strain hardening followed by partial hardening relief to a specific strength level, providing an ideal balance between ductility and yield strength.

From a metallurgical perspective, this partially hard tempering process realigns the atomic structure without causing brittleness, allowing the sheet to retain moderate work-hardening capabilities—highly prized in precision forming applications.

Surface Finish and Paint Adhesion: The Go-To Alloy for Aesthetic Applications

One unconventional angle to appreciate the 5005 H34 alloy is its excellent surface workability combined with superb paint adhesion properties. Compared to grade 3003, the 5005 offers a smoother, cleaner aluminum surface which facilitates longer-lasting painted graphics and industrial coatings. If your manufacturing business involves forming pre-painted panels, decorative equipment:

- Superior anodizing capability ensures you get a brilliant, fade-resistant finish.

- The H34 temper provides physical durability while still enabling multiple bends or curves.

This sets 5005 H34 apart as the aluminum sheet that not only performs but also holds aesthetic appeal.

Corrosion Resistance: A Lifespan Unmatched in Atmospheric Conditions

By virtue of a magnesium-rich alloy and precise tempering, 5005 H34 aluminum resists oxidation and aggressive environmental factors much better than many competing grades. Marine, transportation, and architectural industries especially prize this sheet because it stands strong against saltwater exposure and industrial pollutants without requiring additional thick coatings.

Instead of seeing it merely as a sheet feeder material, imagine the 5005 H34 as an investment in longevity and sustainability—minimizing future costs associated with corrosion repairs or replacements.

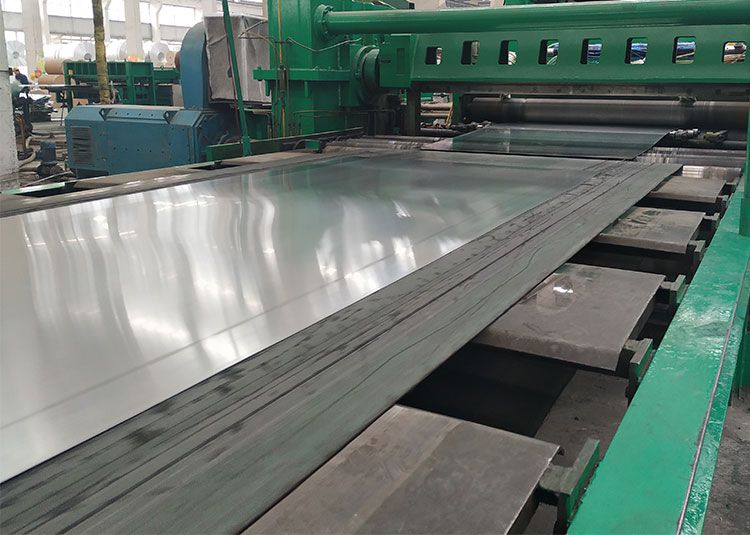

Mechanical Properties: Where Versatility Meets Reliability

mechanical traits to notice include:

- Tensile strength roughly around 150 MPa.

- Yield strength near 130 MPa.

- Elongation percentages hold sufficiently around 8%-10% depending on exact temper conditions.

This makes the 5005 H34 savory not only for simplewindow frames or roofing panels but also for fabricated parts requiring moderate forming. The partly hardened state means welds remain structurally sound without compromising sheet form stability—a common issue with fully hardened sheets.

Common Use Cases from a Solution-focused Lens

The 5005 H34 aluminum sheet's composition and temper present solutions to today’s production challenges:

- Refrigeration products: Acts as lining and clad sheets with corrosion buffer and thermal conductive promises.

- Flat architectural panels: Enables eye-catching façades resistant to environmental insults.

- Plastic lamination bases: For foam or PVC laminated furniture, ensuring flex and tensile demands met without cracking or separating laminates.

- Automotive trim sheets and decorative molding: Symbolizes a simple-to-work-to-paint medium prioritizing cost-effective manufacturing.

When viewed outside the lens of just raw material cost, the 5005 H34 sheet stands tall for customers zeroing in on durability, finishes, processing versatility, and corrosion resistance combined with modest weight. From precision bending to painted panelwork, it yields long-term gains because it reduces total usage costs, labor requirements, and waste.

Interested companies who prioritize product longevity allied with attractive finishes and moderate forming needs should reconsider 5005 H34 as a go-to aluminum alloy sheet immediately. Presenting an optimal solution across hundreds of industries, the 5005 H34 aluminum sheet reveals its true worth yet again—the unsung hero of the aluminum sheet world.

Whether for architectural innovation or industrial longevity, 5005 H34 embodies an ideal balance seldom matched. Explore this versatile metal alloy to uncover new strengths hidden in plain sight for your production lineup!