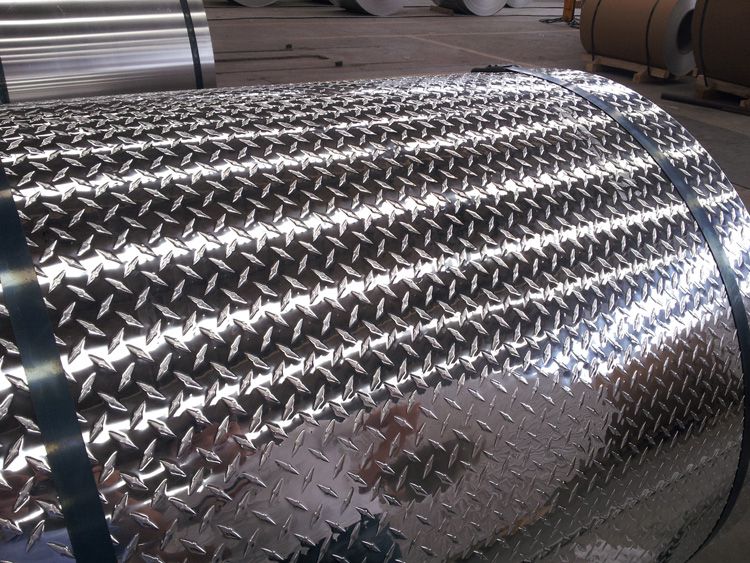

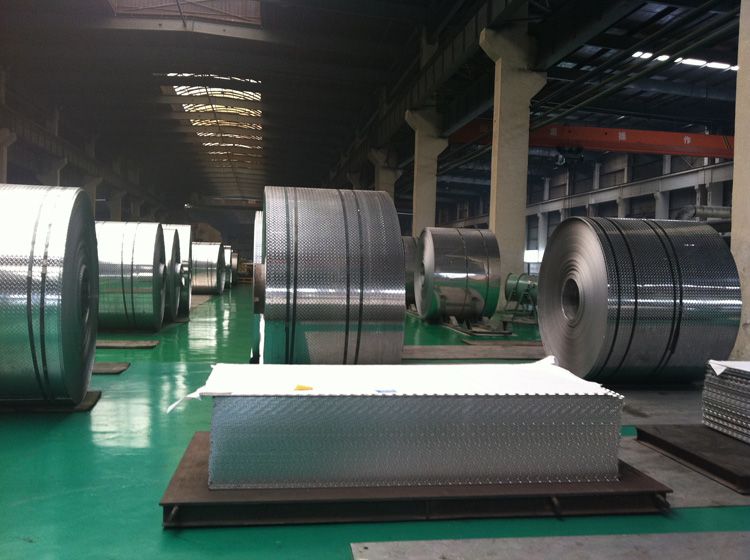

In the world of manufacturing and construction, embossed aluminum sheets have emerged as a material of choice due to their unique blend of strength, lightweight properties, aesthetic appeal, and versatility. Among the available variants, the color anodized aluminum sheets in alloys 1100, 1200, 1230, and 1035 is know due to their myriad of applications and inherent benefits.

Aluminum Alloys and Anodization

Aluminum alloys are categorized based on their chemical composition and specific characteristics that determine their suitability for different applications. Alloys such as 1100, 1200, 1230, and 1035 represent the non-heat-treatable 1xxx series, signifying a high level of aluminum purity, the properties of which include excellent corrosion resistance, high thermal and electrical conductivity, and ease of fabrication.

Color Anodization

Anodization is an electrochemical process that enhances the thickness of the natural oxide layer on the surface of aluminum materials, which not only improves corrosion resistance but also creates a porous surface that can be dyed for aesthetic color enhancements. Color anodized aluminum is particularly appealing for eye-catching design applications in architectural siding, wall cladding, signage, and decorative fencing.

Functions and Applications of Embossed Aluminum Sheets

Decorative and Aesthetic Functions

Embossed aluminum sheets undergo a surface alteration technique that creates patterns, which enhances their look and feel. This texturing not only bolsters visual appeal but also increases surface durability. The interplay between color anodization and embossing results in products that offer both beauty and practicality. Industries ranging from architecture to interior design exhibit a strong preference for these sheets, especially in applications such as:

- Building Facades: With aesthetic appearances and diversity in surface finishes, color anodized embossed aluminum sheets can define modern structures while offering longevity and low maintenance.

- Signage: Lightweight and vibrant, they are perfect for customizable signs, benefiting from embossing that enhances legibility.

- Consumer Electronics: The embossed design is often utilized in products such as cases for mobile devices, where durability and attractiveness are in high demand.

Structural Applications

Beyond decorative use, embossed aluminum panels are deployed in situations requiring weight efficiency combined with rigidity. The chosen alloys, specifically 1100, 1200, 1230, and 1035, abide by numerous application standards. For engineers and manufacturers, the strengths inherent to each alloy can optimize solutions:

- Automotive Components: Lightweight stamped components in vehicles help improve fuel efficiency without sacrificing strength or safety.

- Transport and Container Fabrication: Embossed aluminum sheets contribute to the production of lightweight shipping containers that require superior durability while minimizing overall transport costs.

Physical and Chemical Properties Benchmarks

To fully understand the selections available within the series of color anodized aluminum sheets, let's get into the detailed technical parameters encompassing impact resistance, potential infiltration, tempering states, and chemical resistance.

| Parameter | Aluminum Alloy 1100 | Aluminum Alloy 1200 | Aluminum Alloy 1230 | Aluminum Alloy 1035 |

|---|---|---|---|---|

| Minimum Aluminum Content | 99.0% | 99.0% | 99.0% | 99.0% |

| Yield Strength (MPa) | 85-160 | 70-140 | 60-125 | 75-165 |

| Tensile Strength (MPa) | 120-280 | 90-290 | 80-250 | 100-270 |

| Rockwell Hardness (B) | 25-50 | 15-45 | 20-40 | 30-50 |

| Chemical Resistance | Moderate Tech Resistance | Excellent Tech Resistance | Moderate Tech Resistance | Good Tech Resistance |

| Fabricability Process | Excellent | Excellent | Good | Excellent |

| Temperature Resistance °C | 250 | 250 | 250 | 275 |

Implementations and Standards

These alloys follow implementation standards including:

- ASTM B679 for wrought aluminum and aluminum alloy sheet and plate.

- ASTM B609 and B Anodized Aluminums guide acceptable methods for assessments post-anodization, ensuring expected strength longevity and performance intimation.

Aluminum engraving won’t lose integrity or se serão layers over time, as they may resist weathering, UV degradation, and routine wear owed to the anodized treatment.

Ideal Alloy Selection Based on Intended Use

Choosing among aluminum alloys 1100, 1200, 1230, and 1035 generally revolves around factors such as structural tones, stress environments, climatic concerns, fabrication implications, and budgetary demands.

- Alloy 1100 offers great formability essential for food and chemical handling.

- Alloy 1200, characterized by reduced air leakage, adapts aptly in construction sites concerning thermal insulation demands.

- Olympic Alloy 1230 is its own question with suitability in environments driving engineering realiza such as customs and forlift remix distribution advancement queues.

- Alloy 1035 merges strength balance favorable to extensive fabrication hurdles especially prevalent in major crank equipment leverage about durability typically worth.