ASTM B209 Alloy 3003 aluminium plate is a widely used general-purpose aluminium alloy combining good corrosion resistance, formability, and moderate strength. It is part of the 3xxx series (Mn as the principal alloying element) and is commonly specified for sheet and plate products under the ASTM B209 standard for aluminium and aluminium-alloy sheet and plate.

Alloy 3003 is an aluminium–manganese alloy (AlMn1) with these primary functions:

- Corrosion resistance: Excellent performance in atmospheres and many environments (including mild chemicals and marine atmospheres).

- Formability: Good ductility and deep-drawing characteristics, suitable for complex forming operations.

- Weldability: Readily welded using common fusion and resistance techniques.

- Thermal and electrical conductivity: Good thermal and electrical conductivity typical of commercial aluminium.

- Moderate strength: Higher strength than pure aluminium (1100) due to Mn addition, while remaining easily worked.

Because of this combination, 3003 is used where moderate strength, excellent forming, and corrosion resistance are required at a reasonable cost.

Standards and Specifications

Primary standards that cover 3003 aluminium plate / sheet include:

- ASTM B209 — Standard Specification for Aluminium and Aluminium-Alloy Sheet and Plate

- ASTM B209M — Metric version of ASTM B209

- AMS-QQ-A-200/8 and various military/industry specifications reference 3003 for some applications

- EN 485 / EN 573 / EN 755 may be referenced for European equivalents (EN designations differ; 3003 roughly aligns with EN AW-3003)

When ordering, specify material designation (3003), product form (plate/sheet), temper (O, H14, H16, H18, etc.), thickness, width, length, and applicable standard (e.g., ASTM B209).

Chemical Composition

Typical chemical composition for Alloy 3003 (in weight percent) is shown below. Note that allowable tolerances depend on the standard and specification; the table shows typical ranges and common maximum limits per ASTM/AA conventions.

| Element | Typical (wt%) | Specification Limits (approx.) |

|---|---|---|

| Aluminium (Al) | Balance | Balance |

| Manganese (Mn) | 1.0–1.5 | 1.0–1.5 max |

| Copper (Cu) | 0.05–0.20 | 0.05–0.20 max |

| Iron (Fe) | 0.6–0.7 | 0.7 max |

| Silicon (Si) | 0.12–0.6 | 0.6 max |

| Zinc (Zn) | 0.05–0.20 | 0.10–0.20 max (varies) |

| Titanium (Ti) | 0.01–0.10 | 0.15 max |

| Chromium (Cr) | 0.05–0.20 | 0.20 max |

| Others (each) | ≤0.05 | As specified (total others ≤0.15–0.20) |

(Reference: Aluminum Association / ASTM typical compositions. Always consult the specific material mill cert for exact values.)

Temper Designations and Treatments

3003 is a non-heat-treatable alloy whose strength is controlled by strain hardening (work hardening) and temper designations include:

| Temper | Description | Typical Effects |

|---|---|---|

| O | Annealed (softest) | Maximum ductility, best formability |

| H14 | Strain-hardened to quarter-hard | Moderate strength; good formability |

| H16 | Strain-hardened and partially annealed | Balance of strength and formability |

| H18 | Strain-hardened to half-hard | Higher strength, less ductile |

| H24 | Strain-hardened and stabilized | Improved creep resistance and dimensional stability |

Selection depends on forming requirements and required strength. For deep drawing and complex forming, O or H14 is common. For applications requiring higher strength or stiffness, H18 may be chosen.

Mechanical Properties (Typical)

Mechanical values vary with temper, thickness, and production method. Typical ranges for common tempers are:

| Property | Temper O | Temper H14 | Temper H18 |

|---|---|---|---|

| Tensile strength (MPa) | 70–110 | 120–180 | 190–240 |

| Yield strength (0.2% offset, MPa) | 35–60 | 60–120 | 120–160 |

| Elongation (%) | 20–40 | 10–25 | 5–15 |

| Hardness (Brinell) | ~30 HB | ~40–60 HB | ~60–80 HB |

| Density (g/cm3) | 2.70 | 2.70 | 2.70 |

(Values are indicative. Actual certified values should be taken from mill test reports and relevant standards.)

Physical and Thermal Properties

| Property | Value |

|---|---|

| Density | ~2.70 g/cm3 |

| Melting range | ~640–650 °C |

| Thermal conductivity | ~130–150 W/m·K (approx., depends on temper) |

| Electrical conductivity | ~34–35 % IACS (approx.) |

| Coefficient of thermal expansion | ~23.8 ×10^-6 /°C (20–100 °C) |

Fabrication Characteristics

- Forming: Excellent — suitable for rolling, deep drawing, spinning, bending, stamping.

- Welding: Good — compatible with MIG, TIG, resistance welding. Pre- and post-weld cleaning recommended to avoid contamination. Not heat-treatable for strengthening, so weld areas will have similar properties to base metal depending on heat input.

- Machining: Fair — standard machining practices for aluminium; use proper tooling and speeds to avoid built-up edge and ensure surface finish.

- Joining: Mechanical fastening (rivets, screws) is common; adhesive bonding also feasible with appropriate surface preparation.

- Surface treatment: Can be anodized with limited enhancement of appearance (3003 may anodize to light/clear finishes but is not as ideal as 5xxx/6xxx alloys for thicker decorative anodizing). Also suitable for painting and powder coating after pretreatment.

Corrosion Resistance

3003 offers good corrosion resistance in many environments, including outdoor and mildly corrosive (urban and marine) atmospheres. Manganese improves strength without significantly reducing corrosion resistance compared to pure aluminium. For aggressive environments (chloride-heavy marine or chemical exposure), 5xxx or clad aluminium may be considered.

Typical Applications

Alloy 3003 plate and sheet are used across many industries:

- Architectural building components: roofing, siding, gutters, downspouts, awnings.

- Consumer products: cookware, heat exchangers, appliances (refrigerators, freezers), vending machines.

- Chemical equipment: storage tanks, ducting, and process components for mild chemicals.

- Transportation: truck and trailer panels, siding, interior trim.

- Food and beverage industry: food processing equipment, storage containers (non-critical chemical exposure).

- Signage, nameplates, and decorative trim.

- Pressure vessels and tanks for non-critical or low-pressure applications.

- Electrical and thermal applications: heat exchangers, fins and reflectors.

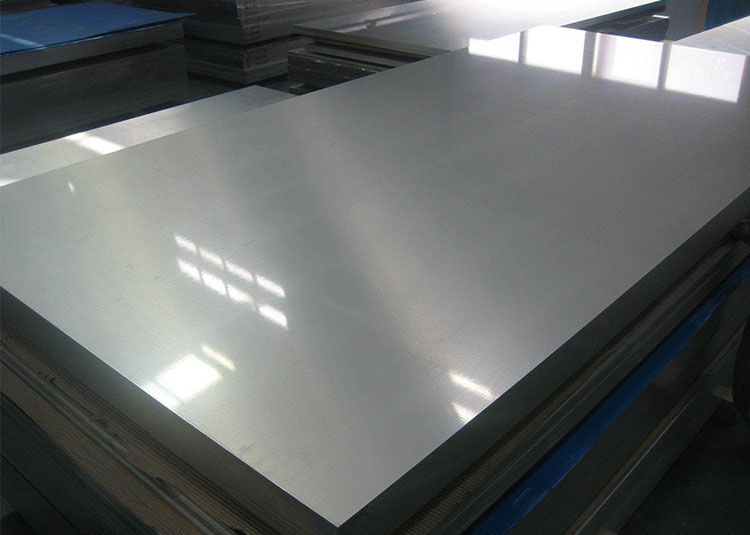

Typical Plate/Sheet Sizes and Thickness

ASTM B209 covers a range of sheet and plate thicknesses. Common commercial plate/sheet thicknesses for 3003:

| Product Form | Typical Thickness Range |

|---|---|

| Sheet | 0.2 mm – 6.0 mm |

| Plate | >6.0 mm – 120 mm (typical mill capabilities vary) |

Widths and lengths depend on mill capabilities — common widths up to 1500–2000 mm or wider; custom slitting and cut-to-length available.

Quality Control and Testing

Common inspection and testing performed per ASTM B209 or customer requirements:

- Chemical composition analysis (spectrographic or chemical analysis)

- Mechanical testing: tensile, yield, elongation

- Hardness testing

- Dimensional checks (thickness, flatness)

- Surface quality inspection (finish, defects)

- NDT if requested for critical applications

- Mill test certificate (MTC) and traceability to lot/batch

Design and Usage Considerations

- Thickness and temper selection should balance formability, strength, and weight.

- For deep drawing, specify fully annealed (O) or light work-hardened (H14) tempers.

- For higher strength or where surface finish is important, consider temper and surface treatment options.

- For marine or highly corrosive environments, evaluate 5xxx series alloys (e.g., 5083) or cladding for increased corrosion resistance.

- Always consult mill test certificates for exact chemical and mechanical properties for a given production run.

ASTM B209 Alloy 3003 aluminium plate is a versatile, corrosion-resistant, formable, and weldable sheet/plate alloy suitable for a wide range of architectural, industrial, and consumer applications. Its moderate strength and excellent forming characteristics make it a common choice where cost-effective, reliable aluminium performance is required. When specifying 3003 plate, include temper, thickness, and the governing standard (ASTM B209) and request mill certifications for critical applications.