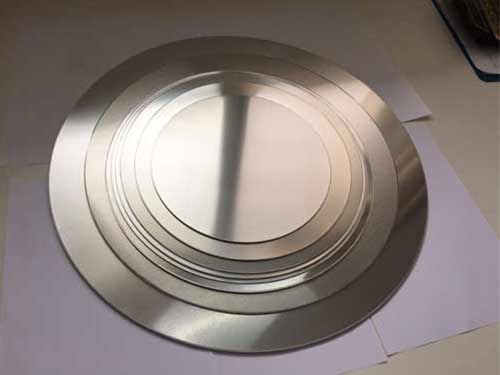

In the realm of aluminum products, 3003 H12 aluminum discs is know for their exceptional performance and adaptability across various sectors. With a natural ability to form, resist corrosion, and present excellent thermal conductivity, this alloy is often the undisputed choice for professionals time and time again.

3003 H12 Aluminum Discs

3003 is a designation within the Aluminum Association Alloy series that signifies a specific alloy that combines aluminum with a minimal amount of manganese (approximately 1.0-1.5%). The temper designation 'H12' points to its hardening via strain, exhibiting a Work-Hardened condition. Structuring materials within these parameters and standards ensure the optimal performance of 3003 H12.

Here's a detailed look at some integral properties that shape the characteristics of 3003 H12 discs:

Chemical Properties

| Element | Wt% (Composition) |

|---|---|

| Aluminum (Al) | Bal. |

| Manganese (Mn) | 1.0 - 1.5 |

| Silicon (Si) | 0.5 |

| Iron (Fe) | 0.7 |

| Copper (Cu) | 0.2 |

Physical and Mechanical Properties

To paint a clearer picture of its attributes, we assess its parameters in various contexts of applications:

| Property | Value |

|---|---|

| Density | 2.73 g/cm³ |

| Yield Strength | 145 MPa |

| Ultimate Tensile Strength | 180 MPa |

| Elongation at Break (%) | 22% |

| Melting Point (°C) | 600 |

Implementation Standards

To realize the potential of 3003 H12 aluminum discs, alignment with industry standards is imperative. They conform to ASTM B209/B209M specifications for Aluminum and Aluminum-Alloy Sheet and Plate, ensuring that users can depend on its quality for tasters applications.

Applications

Cooking and Kitchenware:At the confluence of form and function, 3003 H12 aluminum discs serve efficiently as base materials for cookware like saucepans, stock pots, and non-stick frying pans. Due to its excellent thermal conductivity, they ensure rapid and homogeneous heat distribution.

Automotive Road Safety:The glory of the 3003 H12 disc lies within its application in non-slip surfaces alongside general purpose trimmings in aluminum fabrications used for automotive bodies or components. Its strength while being lightweight improves both fuel efficiency and road safety.

Electrical Equipment:Electrical appliances such as connectors, heat exchangers, and even transformer roosters have found significant benefit in using 3003 H12 aluminum discs; they ensure high-performance while safeguarding against corrosion, thereby prolonging lifecycle of parts.

Aesthetic Applications:Surface treated forms of these disc shapes lend well to decorative design — furniture, appliance enclosures, and more engage consumers reflective of modern design complexities.