5086 H112 is a highly regarded marine-grade aluminum alloy sheet known for its excellent corrosion resistance in seawater, good weldability, and high strength for a non-heat-treatable alloy. It is widely used in shipbuilding, marine structures, and other offshore applications where durability in a chloride environment is required.

Features (At a glance)

- Excellent resistance to seawater and chloride corrosion

- Good strength for a strain-hardened (H112) alloy

- Good weldability and brazability using standard techniques

- Good formability for moderate forming operations

- Non-heat-treatable; strengthened by strain hardening and controlled composition

- Suitable for pressure vessels, hull plating, decks, and structural components in marine environments

Chemical Composition (Typical)

The following table shows typical elemental limits for 5086 per common standards (values in wt%):

| Element | Min (%) | Max (%) |

|---|---|---|

| Al | Balance | — |

| Mg | 4.0 | 4.9 |

| Mn | 0.2 | 0.7 |

| Cr | 0.05 | 0.25 |

| Fe | — | 0.4 |

| Si | — | 0.25 |

| Cu | — | 0.1 |

| Zn | — | 0.25 |

| Ti | — | 0.15 |

| Others (each) | — | 0.05 |

| Others (total) | — | 0.15 |

Notes:

- Composition ranges may vary slightly by specification (e.g., ASTM B209/B928, EN AW-5086). Always refer to the purchasing specification or mill certificate for exact limits for a given lot.

Temper Designation — H112

- H112 indicates the product is in an undetermined but stable strain-hardened condition, typically achieved by controlled rolling or cold working. It is commonly used for sheet and plate where a specific degree of strain hardening is not specified but mechanical properties are better than annealed (O) temper.

- The H112 temper provides improved strength while maintaining good ductility and formability for marine fabrication.

Mechanical Properties (Typical for Sheet/Plate, H112)

The following are representative values; actual properties depend on thickness and supplier processing:

| Property | Typical Value |

|---|---|

| Tensile Strength (UTS) | 275 – 350 MPa |

| Yield Strength (0.2% offset) | 120 – 200 MPa |

| Elongation (in 50 mm) | 7 – 15 % |

| Hardness (Brinell) | 55 – 75 HB |

| Density | 2.66 g/cm³ |

Notes:

- Thinner sheet products in H112 often show higher yield and tensile values due to greater strain hardening.

- Supplier mill certificates will report measured mechanicals for each production lot.

Physical and Thermal Properties

| Property | Value |

|---|---|

| Density | 2.66 g/cm³ |

| Melting Range | 582 – 652 °C |

| Thermal Conductivity (approx.) | 130 – 140 W/m·K (at 25 °C) |

| Electrical Conductivity | ~34 – 36 % IACS (varies with alloy condition) |

| Coefficient of Thermal Expansion | 23.6 µm/m·K (20–100 °C) |

Corrosion Resistance

- 5086 possesses excellent resistance to seawater corrosion due to its relatively high magnesium content (4–4.9% Mg).

- Good performance in naturally corrosive marine environments; resistant to pitting and crevice corrosion compared to many other aluminum alloys.

- Corrosion rate and mechanism depend on fabrication details (welding, joints), surface finish, and presence of dissimilar metals — use appropriate design and cathodic protection when necessary.

Weldability and Fabrication

- Weldability: Very good. Suitable for GTAW (TIG), GMAW (MIG), SMAW (stick) with compatible filler materials such as 5356 (ER5356) or 5183 (ER5183) depending on service and post-weld requirements.

- Welding considerations:

- Precipitation or intergranular corrosion in weld zone is minimal compared with some aluminum alloys.

- Use appropriate filler alloy to maintain ductility and corrosion resistance.

- Avoid over-aging or extensive localized heating that could reduce strength locally.

- Formability:

- Good for moderate bending and stamping in H112 temper.

- For severe forming, consider intermediate anneal or choose a different temper.

- Machinability:

- Fair; typical aluminum machining practices apply. Use sharp tools, appropriate speeds, and coolant as needed.

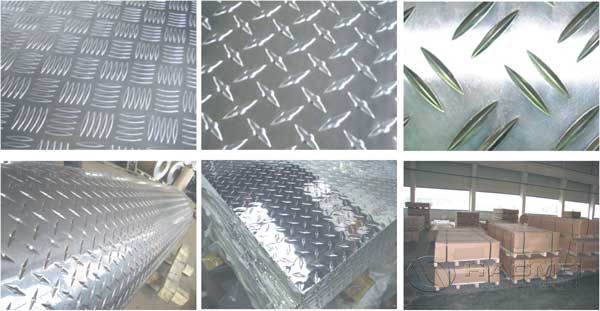

Surface Finishes and Treatments

- Common finishes: mill finish, anodizing (limited by high Mg content; anodize parameters optimized), painting and coating (epoxy/polyurethane), chemical conversion coatings (e.g., chromate or non-chromate alternatives).

- Surface preparation: remove contaminants, use suitable etching/conditioning prior to conversion coatings or painting for best adhesion.

- For visible marine applications, cosmetic finish and coating system selection should consider exposure, UV, abrasion, and salt spray.

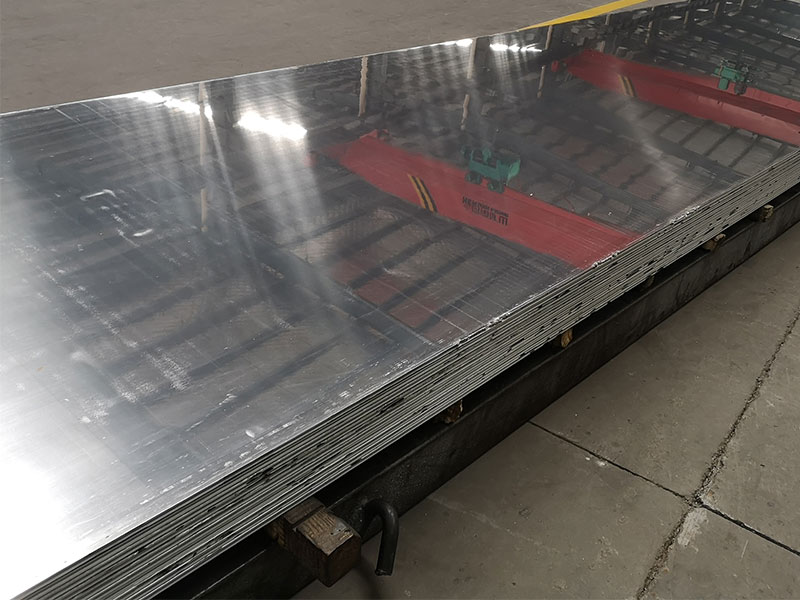

Typical Product Forms and Sizes

| Form | Typical Thickness Range |

|---|---|

| Sheet | 0.8 – 6.0 mm |

| Plate | 6.0 – 50 mm (varies by mill) |

| Coils | available for thin sheet (supplier dependent) |

Custom widths, lengths, and cut-to-size services are commonly offered by mills and distributors.

Applications

5086 H112 is particularly suited for marine and offshore environments. applications include:

- Ship and boat hulls, superstructures, and decks

- Bulkheads and interior structural panels

- Offshore platforms and equipment housings

- Ferries, patrol craft, and workboats

- Pressure vessels and cryogenic tanks (where non-heat-treatable alloys are specified)

- Corrosion-resistant fabricated parts: tanks, piping supports, ladders, and walkways

- Automotive and rail components where corrosion resistance and moderate strength are required

Design and Engineering Considerations

- Thickness selection: thicker plate provides greater stiffness and resistance to buckling but may be heavier and require different welding techniques.

- Joining: specify appropriate weld filler, joint design, and post-weld inspections. Consider mechanical joining (bolts, rivets) with isolation to prevent galvanic corrosion to dissimilar metals.

- Protective coatings and cathodic protection should be considered for long-term service in aggressive marine environments.

- Finite element and fatigue considerations: aluminum has different fatigue behavior than steel; design details (notches, weld toes) should be optimized.

Quality and Standards

Common specifications and standards that reference 5086 include:

- ASTM B209 — Aluminum and Aluminum-Alloy Sheet and Plate

- ASTM B928 — Standard Specification for Aluminum-Alloy Rolled or Cold Finished Bar, Rod, and Wire

- ISO / EN standards may list AW-5086 equivalents (EN AW-5086)

- Lloyd’s Register, ABS, DNV, and other classification societies provide guidance and approvals for marine use — verify material certificates and mill test reports for classed vessels.

Handling, Storage, and Safety

- Store flat, dry, and protected from contaminants. Avoid contact with dissimilar metals to reduce galvanic corrosion risk.

- Use proper lifting equipment for plates and coils to avoid bending or damage.

Typical Mechanical Data Table (Example by Thickness)

Note: Example typical mechanical values — confirm with supplier mill certificate.

| Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 1.0 – 2.0 | 310 – 350 | 160 – 200 | 8 – 12 |

| 2.0 – 6.0 | 275 – 320 | 140 – 180 | 10 – 14 |

| 6.0 – 12.0 | 275 – 300 | 130 – 160 | 12 – 15 |

5086 H112 marine grade aluminium alloy sheet is an excellent choice when strong, corrosion-resistant, weldable, and formable material is required in marine environments. Its high Mg content provides superior seawater resistance, while the H112 temper balances strength and ductility for fabrication. Selection of appropriate thickness, welding filler, coatings, and compliance with relevant standards ensures long service life in demanding offshore and shipbuilding applications.