The Standard ASTM 3003 Aluminium Plate (commonly referred to as AA3003 or 3003-H14/H24/H18, depending on temper) is an aluminum–manganese alloy widely used for general-purpose sheet and plate applications. It combines good formability, moderate strength, excellent corrosion resistance, and good weldability. These properties make 3003 plates a versatile, cost-effective choice across architectural, industrial, and consumer applications.

- Alloy: 3003 (Aluminum — Mn as primary alloying element)

- Standard: ASTM (commonly referenced standards include ASTM B209 (sheet & plate), ASTM B221 (extruded), or ASTM B209/B221 equivalents depending on form). For plate, ASTM B209 is typical.

- Tempers: H14, H18, H24, O (annealed), H112 (as designated by producer)

- strengths: Good formability, corrosion resistance, weldability, and moderate strength higher than pure aluminum (1000 series)

Features

- Chemical composition controlled to ensure consistent performance

- Excellent resistance to atmospheric corrosion and many chemical environments

- Good workability: suitable for bending, forming, stamping, and drawing

- Good brazing and welding characteristics (TIG, MIG, resistance welding)

- Recyclable and lightweight — favorable strength-to-weight for many structures

- Cost-effective alternative to higher-strength alloys where extreme strength is not required

Chemical Composition (Typical / ASTM Limits)

| Element | Typical (%) | ASTM 3003 Limits (%) |

|---|---|---|

| Aluminium (Al) | Balance | 97.0–99.5 |

| Manganese (Mn) | 1.0–1.5 | 1.0–1.5 |

| Iron (Fe) | 0.4–0.7 | 0.7 max |

| Copper (Cu) | 0.05–0.2 | 0.20 max |

| Silicon (Si) | 0.2–0.6 | 0.6 max |

| Zinc (Zn) | 0.05–0.2 | 0.1–0.2 max (varies by spec) |

| Titanium (Ti) | 0.02–0.1 | 0.15 max |

| Chromium (Cr) | 0.02 max | 0.1 max |

| Others (each) | trace | 0.05 max |

| Residuals (total) | — | 0.15–0.20 max |

Notes:

- "Balance" denotes the remainder of the alloy is primarily aluminium.

- Exact limits depend on the specification and producer; the table shows typical values and commonly quoted ASTM limits.

Mechanical Properties (Typical by Temper)

| Property | O (annealed) | H14 (quarter‑hard) | H18 (half‑hard) | H24 (strain‑hardened & partially annealed) |

|---|---|---|---|---|

| Ultimate Tensile Strength (MPa) | 110–130 | 145–165 | 170–205 | 150–175 |

| Yield Strength 0.2% (MPa) | 35–55 | 90–125 | 120–145 | 95–120 |

| Elongation (%), 50 mm | 20–35 | 8–12 | 6–10 | 8–12 |

| Hardness (HB) | 25–40 | 40–55 | 50–65 | 40–55 |

| Density (g/cm3) | 2.70 | 2.70 | 2.70 | 2.70 |

Notes:

- Values are typical; specific temper designations and manufacturing process can shift numbers.

- Always consult mill certificates for exact mechanical data for a given plate heat and temper.

Physical Properties

| Property | Value |

|---|---|

| Melting Range | 645–665 °C |

| Thermal Conductivity (20 °C) | ≈ 136–150 W/m·K |

| Electrical Conductivity | ≈ 29–36% IACS (varies with temper) |

| Specific Heat (20 °C) | ≈ 0.9 kJ/kg·K |

| Modulus of Elasticity | ≈ 69 GPa |

Typical Dimensions & Tolerances

| Parameter | Typical Range | Notes |

|---|---|---|

| Plate thickness | 0.5 mm – 150 mm (varies by mill) | Common plate gauges: 1–25 mm for general use |

| Width | Up to ~2,500 mm or custom | Mill capability dependent |

| Length | Cut to order | Standard or customized lengths |

| Thickness tolerance | ±0.05 mm to ±0.5 mm (depends on thickness and spec) | See ASTM B209 for specifics |

| Flatness & edge condition | Mill, slitted, sawn, or saw-filed | Depends on customer requirements |

Performance Characteristics

- Corrosion Resistance: Excellent in atmospheric and mildly corrosive environments. Performs well against rusting and pitting compared to steels; suitable for outdoor architectural use, ductwork, and HVAC components.

- Formability: Good drawability and formability for H14/H18/H24 tempers; O condition offers highest ductility for deep drawing.

- Weldability: Good; common welding methods (MIG, TIG, resistance) are effective. Some loss in strength in heat-affected zones is typical; consider design for welded joints accordingly.

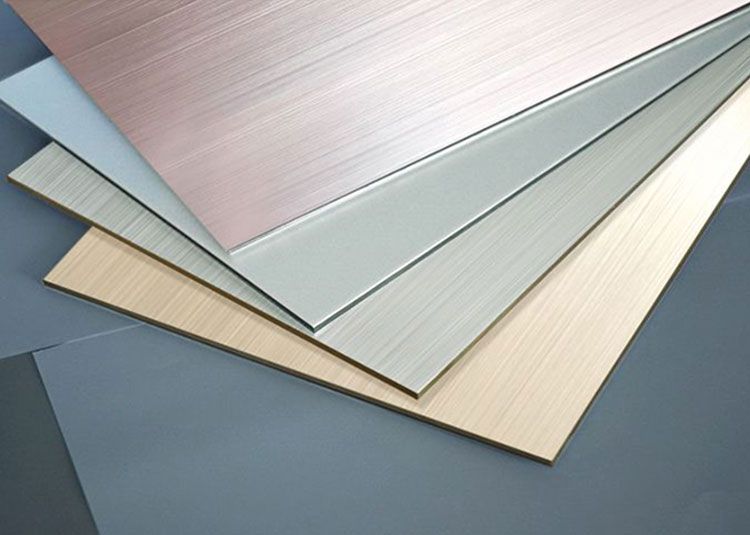

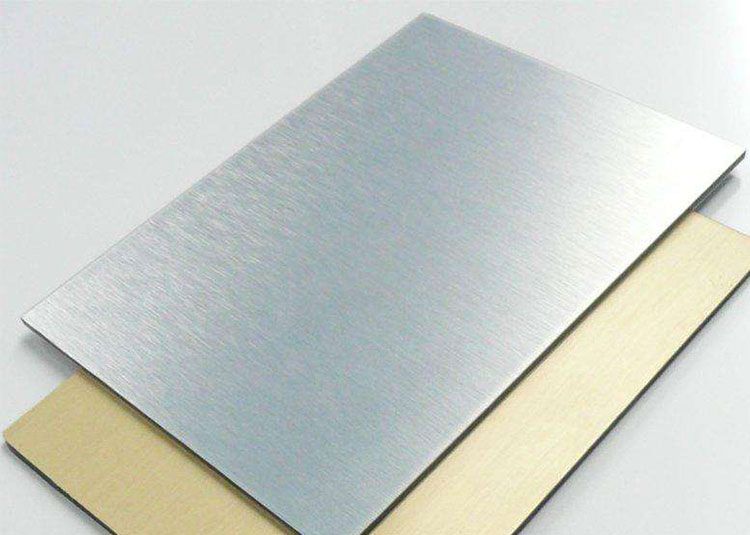

- Surface Finish: Available in mill finish, bright finish, or further processed (anodized, painted, coil-coated). Anodizing improves appearance, hardness, and corrosion resistance.

- Fatigue Behavior: Moderate; not intended for high-cycle, high-stress dynamic loading where high-strength alloys are required.

- Thermal and Electrical Conductivity: Good thermal conduction and fair electrical conductivity suitable for heat exchange and non-critical electrical applications.

Common Applications

- Architectural panels, roofing, cladding, gutters, and downspouts

- HVAC components: ducts, plenums, and heat exchangers

- Food and chemical handling equipment where non-toxic and corrosion resistance is required

- General fabrication: cabinets, enclosures, electrical housings, and signage

- Consumer goods: cookware rims, appliance parts, and fixtures

- Transport bodies and components where moderate strength and light weight are advantageous (trailers, interior panels)

- Decorative trim and furniture components

- Pressure vessels of low/medium pressure where 3003 properties meet requirements (consult codes)

Advantages & Benefits

- Cost-effective: Lower alloying and processing costs compared to higher-strength series

- Versatile: Suitable for numerous fabrication processes (forming, welding, machining)

- Durable: Good resistance to corrosion, especially in outdoor and marine-proximate atmospheres

- Recyclable: Aluminium is highly recyclable without loss of properties, improving sustainability credentials

- Consistent supply: Widely produced and stocked, with standardized chemistry and temper options

- Finish options: Easily anodized or coated for enhanced aesthetics and corrosion protection

Fabrication & Handling Guidance

- Cutting: Shearing, sawing, and laser cutting are common. Use suitable cutting speeds to avoid work hardening or burrs.

- Forming: Use appropriate tooling radii and blinds; anneal (O temper) for severe forming to reduce cracking.

- Welding: Use compatible filler alloys (e.g., ER4043 or ER5356 depending on joint needs). Clean surfaces prior to welding to remove oxides and contaminants.

- Surface treatment: For anodizing, ensure alloy surface cleanliness and control of anodizing parameters to achieve uniform finish.

- Machining: Low to moderate speeds and feeds; use carbide tooling for best results. Clamping should avoid distortion on thin plate.

- Storage: Keep dry and protected from prolonged exposure to corrosive environments prior to finishing.

Inspection & Quality Control

- Mill Test Certificates (MTC) should accompany shipments to verify chemical composition and mechanical properties per ASTM standards.

- Visual inspection for surface defects (scratches, pits, roll marks) per customer specs.

- Dimensional checks against ordered tolerances: thickness, flatness, length, and width.

- Nondestructive testing (NDT) for critical uses—e.g., ultrasonic testing for internal defects; dye penetrant for surface cracks.

- Hardness and tensile testing may be performed per lot or upon request.

Typical Specification References

- ASTM B209 — Aluminum and Aluminum-Alloy Sheet and Plate

- AMS 4023 / QQ-A-250 (older specs) — where applicable

- ISO 209-1 / EN 573-3 — international equivalents for chemical/mechanical definitions

- Refer to supplier/mill for exact temper designations and any additional proprietary specifications

Selection Considerations

- If your application requires higher strength or improved fatigue resistance, consider alloys such as 5052, 6061, or 5083.

- For deep drawing or severe forming, choose O temper or appropriate pre-treatment anneal.

- For superior corrosion resistance in marine environments, 5083 or 5086 may be preferable.

- For decorative and anodized finishes, ensure the alloy and surface prep meet anodizing standards for color and consistency.

Standard ASTM 3003 Aluminium Plate is an economical, easily fabricated alloy plate offering good corrosion resistance, formability, and weldability with moderate strength. It is an excellent general-purpose material for architectural panels, HVAC components, food handling fixtures, enclosures, and many other applications where moderate mechanical properties and good corrosion resistance are required. Proper temper selection, surface treatment, and adherence to fabrication guidelines ensure optimal performance for your application.

For exact mill chemistry, mechanical data, available dimensions, and finish options, please request the mill test certificate and current product datasheet from your supplier or contact your technical sales representative.