When it comes to boat building and marine applications, choosing the right aluminum sheet material is crucial. Marine Grade Aluminum alloys such as 5052, 5083, and 5086 have proven to be incredibly efficient and versatile.

Marine Grade Aluminum is specifically engineered to withstand harsh environmental conditions such as saltwater exposure and extreme mechanical stresses while offering lightweight benefits crucial for buoyancy in marine vessels.

Characteristics

Corrosion Resistance: Protects against marine corrosion due to addition of magnesium and other alloying elements.

Strength to Weight Ratio: Offers high strength while maintaining lower weight, which is vital in enhancing performance and handling of vessels.

Weldability and Formability: These alloys can be easily fabricated and welded, making them favorable for boat construction.

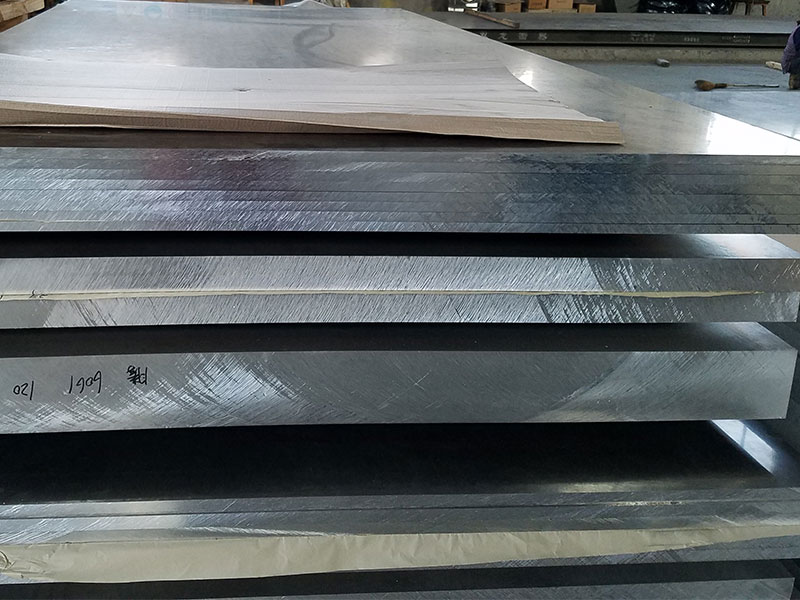

Types of Marine Grade Aluminum Sheets

- 5052 Aluminum Sheet

- One of the most widely used aluminum alloys in marine applications due to its excellent corrosion resistance and formability.

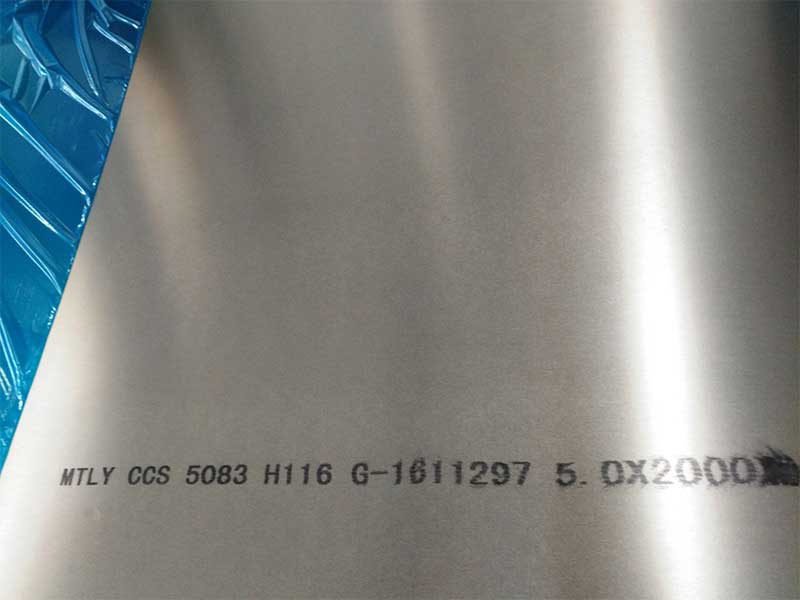

- 5083 Aluminum Sheet

- Known for its exceedingly high resistance to stress corrosion cracking in seawater.

- 5086 Aluminum Sheet

- Provides formidable resistance to marine environments and is widely used for constructing components in boats, ships, and bridges.

Chemical Composition

| Alloy | Magnesium (% Mg) | Silicon (% Si) | Copper (% Cu) | Manganese (% Mn) | Iron (% Fe) | Zinc (% Zn) | Chromium (% Cr) | Aluminum (Remaining %) |

|---|---|---|---|---|---|---|---|---|

| 5052 | 2.2 - 2.8 | ≤ 0.25 | ≤ 0.1 | 0.10 - 0.40 | ≤ 0.4 | ≤ 0.25 | 0.15 - 0.40 | Remainder standardized * |

| 5083 | 4.0 - 4.9 | < 0.4 | ≤ 0.1 | 0.4 - 1.0 | ≤ 0.4 | ≤ 0.25 | 0.05 - 0.25 | Remainder standardized * |

| 5086 | 3.5 - 4.5 | ≤ 0.25 | ≤ 0.1 | 0.4 - 1.0 | ≤ 0.4 | ≤ 0.25 | 0.15 - 0.40 | Remainder standardized * |

*The remaining percentage is comprised primarily of aluminum plus occasionally small amounts of additional elements.

Technical Specifications

| Alloy | Temper | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (BHN) | Typical Thickness Range (mm) |

|---|---|---|---|---|---|---|

| 5052 | H32 | 210 - 250 | 260 - 290 | 12 - 20 | 60 - 90 | 1.0 - 25.0 |

| 5083 | H321 | 265 - 310 | 315 - 370 | 10 - 25 | 70 - 100 | 3.0 - 20.0 |

| 5086 | H116 | 230 - 280 | 285 - 320 | 10 - 20 | 60 - 90 | 2.0 - 24.0 |

Implementation Standards

Marine grades are classified according to several standards globally, including:

- ANSI/ SAE: Alloys and tempers outlined in this commonly refer to notices for domestic and commercial use.

- 29 CFR 1910†(OSHA) and various ISO Standards emphasize marine applications ensuring standardized specifications applicable internationally.

Applications of Marine Aluminum Sheets

5052 Aluminum Sheet Applications

- Fuel Tanks: Its high resistance to corrosion makes it an optimal selection for fuel tanks used in vessels and boats.

- Body Panels: Utilized in the fabrication of body parts in vessels.

5083 Aluminum Sheet Applications

- Marine Vehicle Hulls: Known as the go-to material for creating long-lasting hulls due to its superior corrosion resistance.

- Storage Tanks: Ideal for various chemical and water storage tanks due to its robust design.

5086 Aluminum Sheet Applications

- Structural Components: Extensively used in ship repair and marine structural elements.

- Hulls for Yachts and Leisure Crafts: The strength versus weight ratio enhances aerodynamics and cruising performance.