In the evolving world of electronics manufacturing, "PCB aluminium" has emerged as a critical material, especially within the realm of power electronics and LED lighting. Although often overshadowed by traditional substrates like FR4 or pure copper bases, aluminium-based PCBs combine superior thermal management, mechanical strength, and cost-effectiveness that make them indispensable in several high-performance applications.

What Exactly is PCB Aluminium?

A PCB (Printed Circuit Board) aluminium substrate, also called a metal core PCB (MCPCB), is a type of circuit board that incorporates an aluminium plate as the base material. Unlike conventional PCBs which are predominantly made with fiberglass-reinforced epoxy resin (e.g., FR4), PCB aluminium incorporates this metal to address critical issues related to heat dissipation, mechanical durability, and electrical performance.

Aluminium provides a unique thermal conductivity advantage, often ranging between 0.7 to 2.0 W/mK, against just ~0.3 W/mK for FR4, enabling it to prop just efficiency when electronics generate intense heat loads. Alongside superior thermal conductivity, it offers a lightweight structural foundation, steady dielectric insulation layers, and exhibits good electromagnetic compatibility.

Functions of PCB Aluminium

- Thermal Management: The aluminium base effectively channels heat from temperature-sensitive semiconductor devices like LEDs, power transistors, and CPUs, propagating heat away to heat sinks or ambient air and thus preventing component degradation.

- Mechanical Strength: Compared to flexible or thin FR4 boards, aluminum-base PCBs provide firmness and rigid support, reducing mechanical strain and enhancing structural integrity in compact, high-vibration environments.

- Electrical Insulation under Harsh Conditions: A dielectric polymer layer sandwiches between aluminium and copper circuit patterns, ensuring excellent electrical insulation while integrating a reliable mechanical bond.

- Miniaturization Enabler: Their ability to remove heat efficiently allows smaller form factors and innovative designs needing high-current circuits without risking thermal runaway or reliability issues.

Applications of Aluminium PCBs

- LED Lighting: Matte thermal management owes its rampant use to the high luminosity LEDs used on such boards that would overheat on FR4.

- Power Supplies & Converters: Especially in sectors like telecommunications and industrial motor control, aluminium PCBs sustain power semiconductor chips.

- Automotive Electronics: Harsh road and environmental conditions mandate robust boards which do not crack or debond under vibration and temperature shifts.

- Consumer Electronics: High-capacity power delivery systems such as portable charging pads use aluminium PCB layers as a thermal stabilizer.

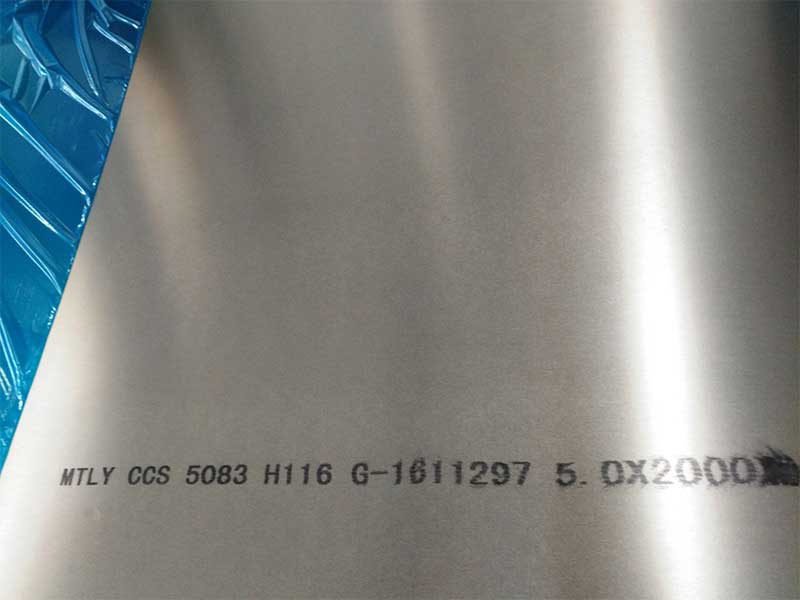

Aluminium Sheet Parameters & Deployment Standards in PCB Aluminium

When aluminium alloy sheets form the metal core PCB, selecting precise material grades and tempering standards defines final performance outcomes.

| Parameter | Typical Values | ASTM/ISO Standards |

|---|---|---|

| Alloy Grade | 1050, 1100, 3003, 5052, 6061 | ASTM B209 (Aluminium Sheets) |

| Thickness Range | 0.2 mm - 1.5 mm | Customized per design |

| Thermal Conductivity | 130 - 220 W/(m·K), depending on alloy | ASTM E1461 |

| Yield Strength | 34-310 MPa (varies across alloy and temper) | ASTM B247 |

| Density | Approximately 2.7 g/cm³ | |

| Coefficient of Thermal Expansion | 22–24 ×10⁻⁶ /°C | ASTM E831 |

| Electrical Resistivity | Approx. 2.65 – 2.82 µΩ·cm | ASTM B193 |

Common Alloy and Tempering Details:

| Alloy | Temper | Description | Implications for PCB Aluminium |

|---|---|---|---|

| 1050 | H14 | Commercial purity, cold worked | High electrical conductivity but lower strength; low thermal resistance |

| 5052 | H32 | Strain-hardened AlMg2.5 | Good corrosion resistance, stronger, widely used for mechanically critical applications |

| 6061 | T6 | Heat-treated AlMgSi alloy | High strength and good corrosion resistance; moderate thermal conductivity |

Chemical Composition Example of 5052 Alloy (% by weight)

| Element | Mg | Cr | Mn | Si | Fe | Zn | Cu | Al (balance) |

|---|---|---|---|---|---|---|---|---|

| % | 2.2–2.8 | 0.15–0.35 | 0.10 | ≤0.25 | ≤0.4 | ≤0.10 | ≤0.1 | Remainder |

Manufacturing Considerations

The fabrication of PCB aluminium combines traditional PCB lamination methods but emphasizes crucial bonding agents to ensure coil stiffness:

- Substrate Lamination: The aluminium sheet is coated with a dielectric insulation layer; generally, polyimide or epoxy does so to provide excellent electrical insulation standardized by IPC-4101 specifications.

- Copper Cladding: Copper foil is laminated atop this dielectric for circuit formation, typically 18 to 70 microns thick.

- Thermal Via Integration: Some designs incorporate thermal vias to expedite heat flow from copper layers to aluminium, supplementing base conductivity.

IPC (Association Connecting Electronics Industries) validates layers’ cohesion and safety with implementation standards such as IPC-4101 Grade PX for Aluminium Core Printed Wiring Boards and IPC-6012 for rigidity and product compliance.

A Distinctive Viewpoint: Aluminium as a Thermal Conduit Integrated with Robust Electronics

Unlike merely considering aluminium’s elemental characteristics in isolation, effectively deploying PCB aluminium pinpoints the integration balance between mechanical formability (firmness in circuitry balance), electrical insulation quality while managing heat, and staying fluid with emerging tech iterations like flexible circuitry and micro-via optimizations.

Material selection along with temper strength renovation offers PCB designers the ability to fine-tune thermal diffusivity, elasticity under die stress, allowing greater reliability in demanding scenarios such as aerospace sensors or drive control modules—where metallurgical mismatches and fatigue might catalyze failure in ordinary PCBs.