Freshness, safety, and shelf appeal are non‑negotiable in modern dairy packaging. The Durable Heat Sealable PP Cap Foil for Milk Bottles with High Barrier Protection is engineered to meet these requirements consistently, combining reliable sealing performance with robust product protection and smooth line efficiency.

The PP cap foil is a multi‑layer, heat‑seal laminate designed specifically for:

- PP (polypropylene) milk bottles and cups

- High‑speed filling and sealing lines

- Extended shelf life for pasteurized, UHT, and ESL milk

It provides:

- Strong, controlled heat seal to PP bottles

- High barrier against oxygen, moisture, and light

- Clean, peelable opening for consumers

- Excellent printability for branding and traceability

Typical Layer Structure

While each customer specification can be customized, the cap foil typically follows a multi‑layer architecture:

| Layer (Top → Bottom) | Typical Material | Function |

|---|---|---|

| Print / Lacquer | Protective lacquer / ink | Graphics, brand color, batch codes, abrasion resistance |

| Outer Support | Aluminum foil | Barrier to light, oxygen, flavors; mechanical strength |

| Tie Layer / Primer | Adhesion promoter | Ensures strong bonding between foil and seal layer |

| Heat Seal Layer | PP-based sealing lacquer | Direct sealing to PP bottle neck / rim |

Note: Exact layer structure and thickness can be tailored to individual bottle designs and filling processes.

Features and Benefits

High Barrier Protection

This cap foil is engineered to protect milk quality from filling through to consumption.

| Barrier Property | Typical Performance Range* | Benefit in Milk Packaging |

|---|---|---|

| Oxygen Transmission Rate (OTR) | < 0.5 cm³/m²·day·bar | Slows oxidation, maintains flavor and nutrients |

| Water Vapor Transmission Rate (WVTR) | < 0.8 g/m²·day (38 °C, 90% RH) | Reduces moisture loss and weight variation |

| Light Barrier | > 99.9% UV & visible light | Protects vitamins (e.g., riboflavin), prevents off‑flavors |

*Values are typical ranges for aluminum‑based cap foils; exact data depend on gauge and structure.

Reliable Heat Seal to PP Bottles

The sealing layer is optimized for direct contact with PP:

| Sealing Parameter | Typical Value / Range |

|---|---|

| Suitable Bottle Material | Homopolymer PP, random copolymer PP |

| Recommended Sealing Temperature | 160 – 220 °C (depending on line speed & dwell time) |

| Sealing Pressure | 2.5 – 5.0 bar |

| Sealing Dwell Time | 0.3 – 1.0 s |

| Peel Strength (to PP) | 2 – 6 N / 15 mm (adjustable) |

The system supports both:

- Peelable seals for easy consumer opening

- Medium‑strong seals for high‑pressure distribution chains

Excellent Mechanical Integrity

The aluminum support layer provides stiffness and tear resistance, while the sealing layer ensures flexibility around the bottle lip.

| Mechanical Property | Typical Value | Relevance |

|---|---|---|

| Total Thickness | 30 – 60 µm | Balanced between flexibility and rigidity |

| Tensile Strength (MD) | 70 – 120 MPa | Withstands automatic handling and capping |

| Elongation at Break | 3 – 8 % | Reduces risk of tearing during sealing and opening |

| Puncture Resistance | High (application‑specific) | Prevents damage during transit and stacking |

Clean, Hygienic Performance

- Low migration inks and coatings designed to comply with food contact regulations

- Smooth, non‑fibrous edges to minimize particulate release

- Compatibility with inline sterilization or disinfection (e.g., UV, peroxide vapor, hot air, or chemical rinses, depending on configuration)

Chemical and Regulatory Profile

The PP cap foil is composed of food‑contact compliant materials, carefully selected to minimize interaction with dairy contents.

Indicative Chemical Composition by Layer

| Functional Layer | Base Component | Typical Contribution (by weight %) |

|---|---|---|

| Aluminum Foil | Al (≥ 99%) | 40 – 70 |

| Heat Seal Layer | PP copolymer + additives | 15 – 35 |

| Primer / Tie | Modified polyolefin / resin | 2 – 8 |

| Ink / Lacquer | Food-grade inks, coatings | 3 – 10 |

| Optional Coatings | Heat / slip / anti‑scratch | 0 – 5 |

Exact composition proportions vary with product design and specification.

Regulatory Alignment

| Regulation / Standard | Typical Compliance Direction* |

|---|---|

| EU Plastics Reg. 10/2011 | For plastic components in direct contact |

| FDA 21 CFR (relevant sections) | Components suitable for use in dairy applications |

| Good Manufacturing Practice | Produced under GMP with traceability |

*Formal compliance statements and migration test reports are typically available on request.

Surface, Printing, and Customization

The top side of the cap foil can be tailored to enhance branding, consumer guidance, and line performance.

Surface Options

| Option | Description | Benefit |

|---|---|---|

| Gloss Varnish | High‑gloss, smooth surface | Premium visual appearance |

| Matte Varnish | Low‑glare, soft touch | Natural, “fresh dairy” look |

| Slip‑Enhanced Coating | Controlled COF (coefficient of friction) | Improved feeding and stacking on line |

| Anti‑Condensation Print | Special pattern / coating design | Condensation visibility reduction |

Printing Capabilities

| Parameter | Typical Range / Option |

|---|---|

| Printing Process | Flexographic, rotogravure |

| Number of Colors | Up to 8 colors |

| Registration | Tight registration for fine artwork |

| Coding | Batch codes, QR codes, traceability |

| Reverse / Face Print | Available depending on structure |

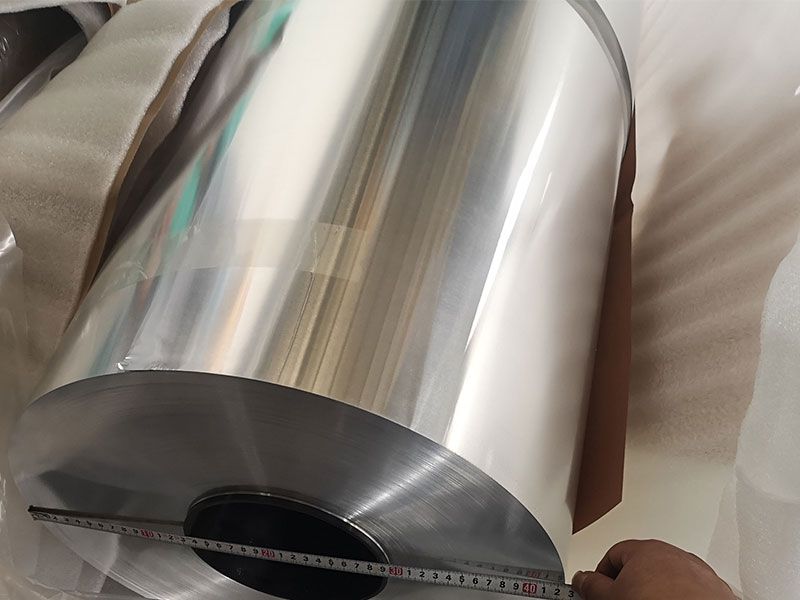

Technical Specifications Snapshot

Below is a concise reference useful for engineering and procurement teams:

| Parameter | Typical Range / Value |

|---|---|

| Base Metal | Aluminum foil |

| Foil Gauge | 20 – 40 µm |

| Overall Laminate Thickness | 30 – 60 µm |

| Heat Seal Layer Type | PP‑based heat‑seal coating |

| Recommended Storage Conditions | 15 – 25 °C, ≤ 60% RH |

| Shelf Life (unopened rolls) | Up to 12 months under recommended storage |

| Core Diameter | 70, 76, or 152 mm (as specified) |

| Roll Width | Customized to bottle neck design |

| Inner Surface | Heat seal PP‑compatible |

| Outer Surface | Printable / lacquered, food‑safe |

Applications in Dairy and Beyond

Core Dairy Uses

The PP cap foil is particularly well‑suited for:

- Fresh pasteurized milk in PP bottles

- Extended Shelf Life (ESL) milk and flavored milk beverages

- UHT milk and cream in PP bottles or small cups

- Drinking yogurt, kefir, and probiotic beverages in PP containers

| Application Type | Requirement | How the Cap Foil Helps |

|---|---|---|

| Pasteurized Milk | Short–medium shelf life, cold chain | High barrier & tight seal |

| UHT / ESL Milk | Long ambient shelf life | Oxygen & light barrier, seal integrity |

| Flavored Milk Drinks | Flavor stability, bright branding | Aroma barrier & high‑quality printing |

| Yogurt / Fermented Dairy | Acidity, live cultures, headspace gases | Robust seal, chemical resistance |

Extended Uses

Beyond milk, the same technology can be adapted for:

- Cream and half‑and‑half

- Non‑dairy beverages in PP (plant‑based drinks, coffee mixes)

- Flavored water and nutritional shakes in PP bottles

Line Integration and Handling

The cap foil is designed for efficient integration into high‑speed packaging lines.

| Aspect | Consideration | Benefit |

|---|---|---|

| Web Handling | Stable, low curl, consistent tension | Reduced line stops and misfeeds |

| Cutting / Punching | Clean die‑cut edges | Minimizes dust and particulates |

| Sealing Technology | Compatible with induction, conduction, or contact heat systems (depending on design) | Flexibility in line setup |

| Waste Management | Optimized for low scrap rates | Lower total packaging cost |

Storage, Transport, and Shelf Life

Proper storage helps maintain the cap foil’s seal performance and appearance.

| Factor | Recommendation |

|---|---|

| Temperature | 15 – 25 °C |

| Relative Humidity | ≤ 60% RH |

| Sunlight | Avoid direct sunlight; store indoors |

| Stacking | Do not exceed specified roll stacking limits |

| Handling | Use protective gloves to avoid contamination |

Under suitable conditions, the material maintains optimal sealing and printing properties for up to 12 months from date of production.

Why Choose This PP Cap Foil for Milk Bottles?

- Purpose‑designed for PP bottle necks in milk and dairy applications

- Provides high oxygen, moisture, and light barrier for superior product protection

- Supports clean, consistent heat sealing at commercial line speeds

- Delivers excellent print quality for strong shelf presence and clear branding

- Built on food‑contact compliant materials with traceability and quality control

Engineers, buyers, and quality managers seeking a reliable, high‑barrier sealing solution for PP milk bottles will find this cap foil a robust, production‑ready choice that balances performance, safety, and cost efficiency.