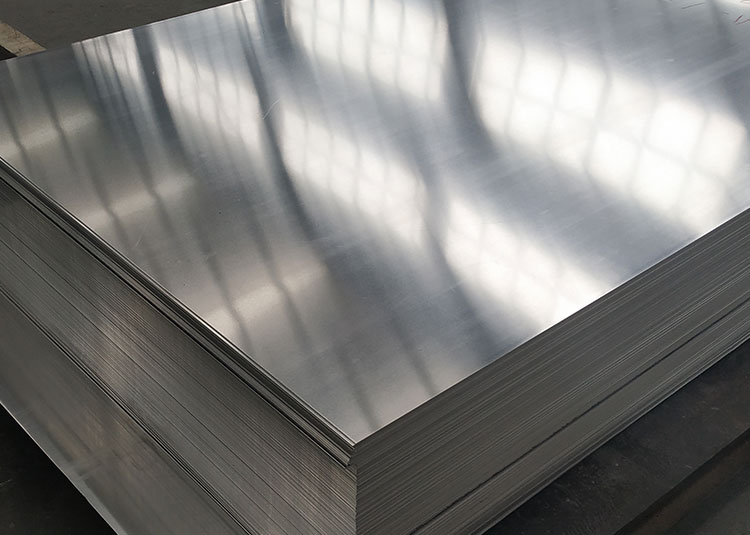

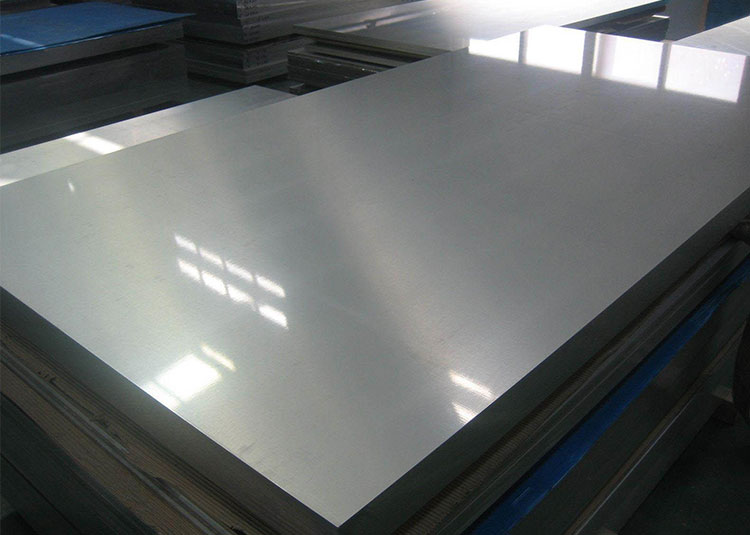

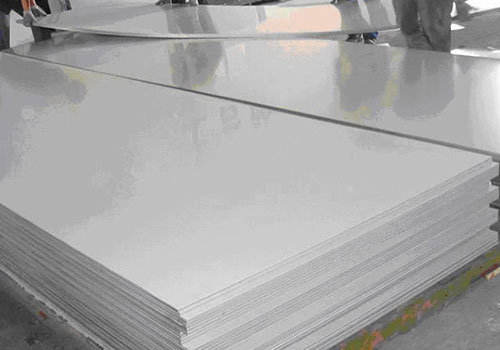

OverviewMirror finished brushed aluminum sheet combines the high reflectivity of a mirror-like surface with the consistent linear texture of a brushed finish. This hybrid surface treatment produces a premium aesthetic: bright, reflective highlights with subtle directional grain that reduces visible fingerprints and disguises minor abrasions. The material offers the durability, corrosion resistance, and lightweight advantage of aluminum while delivering enhanced visual appeal for architectural, decorative, and functional applications.

Product DescriptionMirror finished brushed aluminum sheet is manufactured from high-purity aluminum alloys (commonly 1100, 3003, 5052, and 6061) that are cold-rolled, polished to a mirror sheen, then given a controlled directional brushing to impart fine, uniform linear lines. The result is a sheet with a glossy, metallic luster punctuated by a consistent satin streak—often referred to as “brushed mirror” or “satin mirror.” Typical thickness ranges from 0.3 mm to 6.0 mm, and standard widths include 1000 mm, 1220 mm, 1250 mm, and 1500 mm; custom sizes and coil supply are available.

Features

- Visual appearance: High reflectivity with subtle directional grain provides a luxurious, contemporary look that catches light without the full glare of a plain mirror polish.

- Surface uniformity: Precision brushing ensures consistent grain direction and width across large panels for a seamless finish.

- Durability: Resistant to corrosion, impact, and wear when produced from appropriate alloys and temper; suitable for long-term interior and exterior use.

- Low maintenance: Brushed texture helps to mask fingerprints, smudges, and fine scratches; easy to clean with mild detergents.

- Lightweight and strong: Aluminum’s high strength-to-weight ratio enables rigid, lightweight constructions compared with stainless steel alternatives.

- Formability: Good cold-forming, bending, and roll-forming characteristics; weldable and workable with standard aluminum fabrication methods (punching, cutting, folding).

- Customizable finishes: Available in varying grain sizes (fine, medium, coarse), directional patterns, and protective coatings (PE film, anodized, lacquered) for enhanced scratch and corrosion resistance.

- Environmentally friendly: Recyclable material with low lifecycle environmental impact relative to many metals.

Typical Specifications

- Base alloys: 1100, 3003, 5052, 6061 (other alloys on request)

- Temper: H14, H18, H24, T6 (depending on alloy and application)

- Thickness: 0.3 mm–6.0 mm (custom gauges available)

- Widths: 1000 / 1220 / 1250 / 1500 mm (custom widths/coils)

- Surface finish: Mirror polish followed by directional brushing (grain sizes: #0 (ultra-fine) to #4 (coarse))

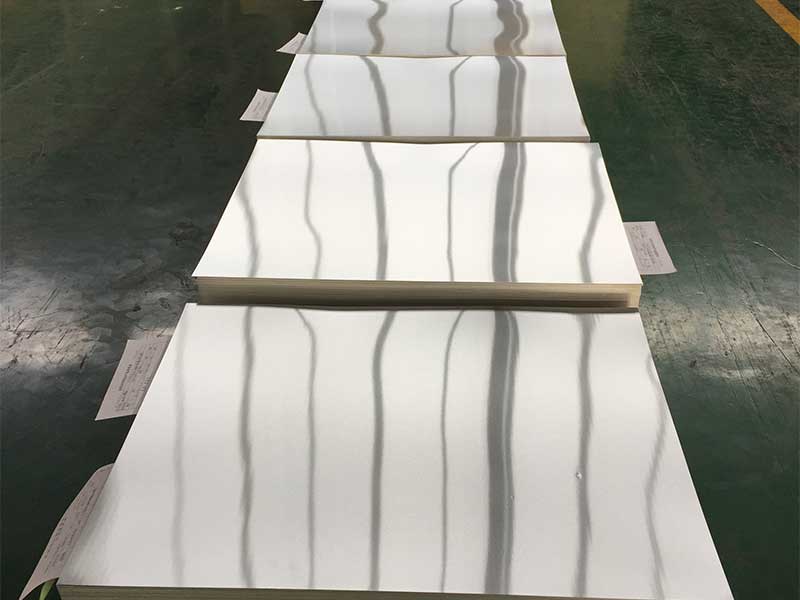

- Surface protection: PE protective film, paper interleaving, or kraft wrap

- Edge condition: Mill edge, trimmed, or deburred to customer spec

- Tolerances: Thickness ±0.02–0.1 mm (dependent on gauge), flatness and width to industry standards

- Packaging: Wooden crate, palletized with corner protectors, suitable for sea/air freight

Chemical Composition (Representative Alloys)Note: Actual composition depends on chosen alloy. Typical ranges shown.

1100 (commercially pure)

Al: balance

Si: ≤0.95%

Fe: ≤0.95%

Cu: ≤0.05%

Mn: ≤0.05%

Zn: ≤0.10%

Ti: ≤0.03%

3003 (Al-Mn alloy)

Al: balance

Mn: 1.0–1.5%

Cu: ≤0.6%

Fe: ≤0.7%

Si: ≤0.6%

5052 (Al-Mg alloy)

Al: balance

Mg: 2.2–2.8%

Cr: 0.15–0.35%

Fe: ≤0.4%

Si: ≤0.25%

6061 (Al-Mg-Si structural alloy)

Al: balance

Mg: 0.8–1.2%

Si: 0.4–0.8%

Cu: 0.15–0.40%

Cr: 0.04–0.35%

Fe: ≤0.7%

Mechanical Properties (Representative)

- 1100 (H14): Tensile strength ~65–105 MPa, Yield ~35–55 MPa, Elongation ~10–30%

- 3003 (H14): Tensile strength ~110–180 MPa, Yield ~60–100 MPa, Elongation ~6–20%

- 5052 (H32): Tensile strength ~210–260 MPa, Yield ~120–200 MPa, Elongation ~7–12%

- 6061 (T6): Tensile strength ~240–310 MPa, Yield ~145–275 MPa, Elongation ~8–12%

Surface Options and Protective Treatments

- Anodizing (clear or color): Improves corrosion resistance, increases hardness, and stabilizes the aesthetic.

- PE lacquer or PVDF coating: Adds chemical and weather resistance for exterior applications.

- Anti-fingerprint coating: Reduces visible smudges for high-touch surfaces.

- Mirror polish depth: Various levels of polish (e.g., 6-8 micron Ra) before brushing to control reflectivity.

- Back-side masking: Adhesive-backed films to protect the reverse during fabrication.

ApplicationsInterior architectural and decorative:

- Wall cladding, feature panels, elevator interiors, reception desks, columns, and ceiling panels where refined metallic finishes are desired.

- Furniture facades, cabinet doors, and shelving accents in retail and hospitality.

- Signage faces and illuminated sign trims requiring high reflectivity and aesthetic texture.

Exterior architectural:

- Building façades, canopies, and sunshades when anodized or coated for weather resistance.

- Decorative metalwork and trim where a premium appearance is required (subject to alloy and coating selection for outdoor exposure).

Transportation and marine:

- Decorative trims, interior panels, instrument panels, and luggage compartments for rail, marine, and commercial vehicles—chosen alloy and coating ensure corrosion resistance in harsh environments.

Appliances and consumer goods:

- Front panels of high-end appliances, audio gear faceplates, and consumer electronic enclosures where appearance and weight savings are important.

Industrial and specialty uses:

- Reflective components that require directional light diffusion, protective covers, and nameplates where readability and style are both factors.

- Food industry surfaces (with appropriate alloy and finish), as brushed surfaces help hide wear and are easy to clean.

Fabrication and Handling Guidelines

- Cutting: Use shearing, laser, waterjet, or CNC routing depending on thickness and finish sensitivity. Test cuts to avoid heat discoloration or burrs.

- Forming: Braking and roll-forming are possible; select larger bend radii to avoid cracking on harder tempers.

- Welding: TIG/MIG welding recommended; post-weld finishing (light brushing or polishing) often required to restore uniform appearance.

- Cleaning: Non-abrasive cleaners or mild detergent solutions. Avoid strong alkalis or acidic cleaners which can dull protective coatings.

- Storage: Store flat in dry, covered conditions. Maintain protective film until final installation to prevent scratches.

Quality Assurance and Testing

- Surface inspection for uniform grain, absence of scoring or polishing defects.

- Thickness measurement and flatness checks to tolerance.

- Chemical analysis (spectrometry) to verify alloy composition.

- Mechanical testing (tensile, yield) on request.

- Corrosion testing (salt spray) for coated or anodized parts where required.

Ordering Information and Customization

- Standard lengths and sizes available from stock; custom sizes, coil supply, and fabrication services available upon request.

- Provide intended application, desired alloy, thickness, grain direction, coating/anodizing preferences, and quantity for accurate quotations.

- Prototype/sample panels can be supplied to verify appearance before full production.

ConclusionMirror finished brushed aluminum sheet offers a unique combination of high reflectivity and subtle satin texture, making it ideal for premium architectural, decorative, and functional applications. With versatile alloy choices, protective treatments, and fabrication compatibility, it provides a durable, lightweight, and visually striking material solution. For project-specific recommendations, supply details on exposure conditions, mechanical requirements, and desired aesthetics so we can propose the optimal alloy, temper, and surface treatment.