Color coated aluminum coil 1100 is a widely used, versatile aluminum product that combines the excellent characteristics of aluminum 1100 alloy with durable and aesthetic color coatings. The result is a high-quality decorative and functional material suitable for a broad range of applications in construction, design, advertising, and industry.

Aluminum 1100 is a commercially pure aluminum (minimum 99% aluminum content), which lends it great advantages such as high corrosion resistance, outstanding thermal and electrical conductivity, and excellent workability.

Basic Chemical Composition of Aluminum 1100:

| Element | Content (%) |

|---|---|

| Aluminum (Al) | 99.0 min |

| Copper (Cu) | 0.05 - 0.20 |

| Iron (Fe) | 0.95 max |

| Manganese (Mn) | 0.05 max |

| Silicon (Si) | 0.95 max |

| Zinc (Zn) | 0.10 max |

| Others | 0.05 max |

By virtue of its purity, 1100 is softer than most aluminum alloys but offers superior corrosion resistance and excellent surface finish qualities, which makes it ideal for color coating processes.

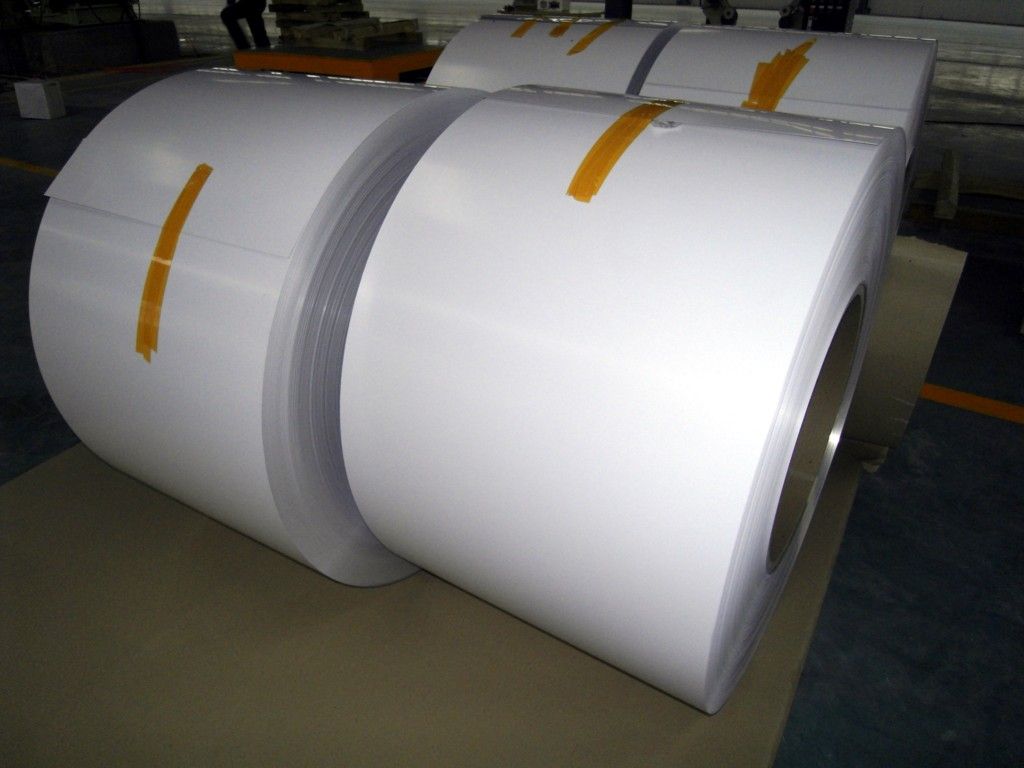

Color Coated Aluminum Coil 1100: What is It?

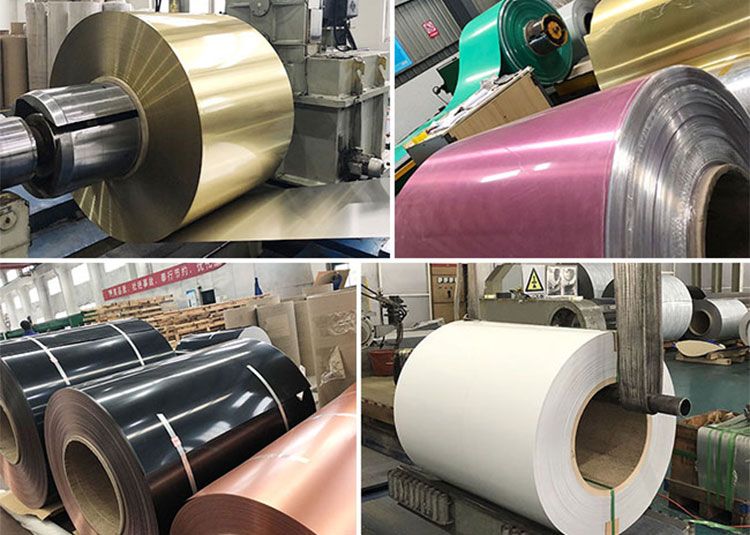

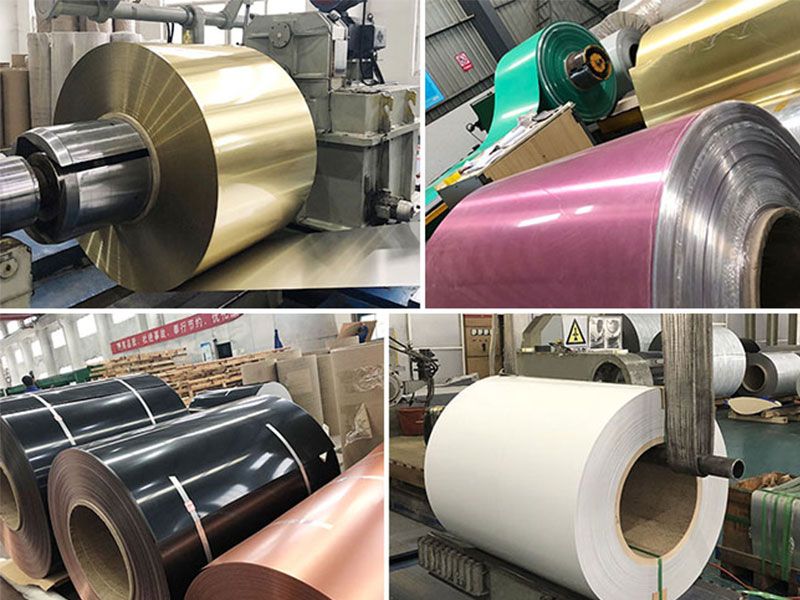

A color coated aluminum coil 1100 starts with an aluminum base coil made from 1100 alloy, which is first pre-treated to remove surface impurities and enhance adhesion. The coil is then coated with layers of inorganic or organic coatings such as polyester (PE), fluorocarbon (PVDF), epoxy, or polyvinylidene fluoride. Multiple coats are applied to assure durability, color uniformity, and resistance to environmental degradation.

Working with 1100 series aluminum coil for color coating presents a unique set of challenges and rewards. Its inherently soft nature makes it incredibly formable, a boon for complex shapes and deep draws in the finished product. However, this softness also means we have to be extra careful during the coating process to avoid scratching or marring the surface. Maintaining consistent coating thickness is paramount – too thin and the color fades quickly, while too thick can lead to peeling or uneven finishes. We’ve experimented with different pretreatment processes to optimize adhesion, and I’ve found that a meticulous cleaning process is to achieving a superior, long-lasting color. A small imperfection in the pretreatment can cascade into significant problems down the line, costing both time and materials.

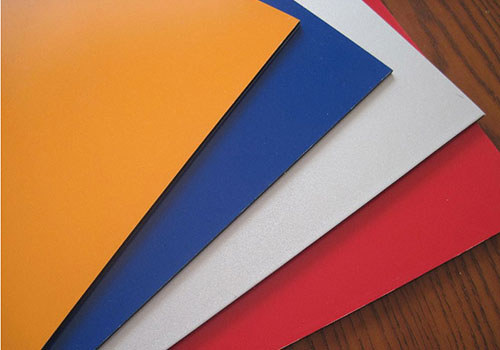

Beyond the technical aspects, there's a certain satisfaction in seeing a raw aluminum coil transformed into a vibrant, finished product. The color choices are seemingly endless, and I've been involved in projects ranging from subtle matte finishes for appliances to bold, high-gloss colors for architectural cladding. Each project presents a new set of specifications, demanding precision and problem-solving skills. Witnessing the final product – a beautiful, durable, and colorful sheet of aluminum – is a testament to the collective effort and meticulous attention to detail across our production line. It’s a far cry from just manipulating metal; it's about creating something aesthetically pleasing and functional that will last for years.

Features of Color Coated Aluminum Coil 1100

| Feature | Description |

|---|---|

| Excellent Corrosion Resistance | Maintains performance in harsh weather, ideal for outdoor use. |

| Vibrant and Durable Colors | Wide range of colors and finishes including matte, gloss, and metallic. |

| Lightweight Yet Strong | Combines the lightness of aluminum 1100 with durable coatings that resist peeling and cracking. |

| Excellent Formability | Easily fabricated into various shapes: bending, stamping, rolling without paint damage. |

| Environmentally Friendly | Recyclable, with coatings designed to minimize volatile organic compounds (VOCs). |

| UV Resistance | Core coatings such as PVDF guarantee long-lasting color retention against ultraviolet exposure. |

| Smooth Surface Finish | Coatings provide an excellent aesthetic finish, smooth texture, and resist dirt buildup. |

Physical and Mechanical Properties of Aluminum 1100

| Property | Value |

|---|---|

| Density | 2.71 g/cm³ |

| Melting Point | 660°C (1220°F) |

| Tensile Strength | 40 – 70 MPa |

| Yield Strength | 35 – 50 MPa |

| Elongation at Break | ~35% |

| Thermal Conductivity | 222 W/(m·K) |

| Specific Heat Capacity | 0.90 J/g·K |

Common Applications of Color Coated Aluminum Coil 1100

Due to its combination of aesthetic, durable finish, and excellent physical properties, Color coated aluminum coil 1100 is prominently used in:

1. Building and Construction

- Exterior wall cladding and facade panels

- Roofing sheets

- Ceiling panels and partitions

- Window shutters and doors

- Interior decoration applications

2. Advertising and Signage

- Billboards and advertising panels offering vibrant colors and weather resistance

- Decorative signage and nameplates

- Illuminated boxes and displays

3. Household Appliances and Furniture

- Exterior cases of refrigerators, microwaves, and air conditioners

- Kitchen appliances with durable and scratch resistant surfaces

- Office decor and furniture laminates

4. Transportation Industry

- Interior panels, lining of vehicles and cabins

- Decorative trims and body parts

5. Packaging Industry

- Rigid packaging requiring antibacterial and corrosion-resistant properties

- Food packaging lines for its non-toxic coatings and good forming