Embossed aluminum sheet Deep Drawing 1050 1060 Mill Finish

10/21 2025 Leo

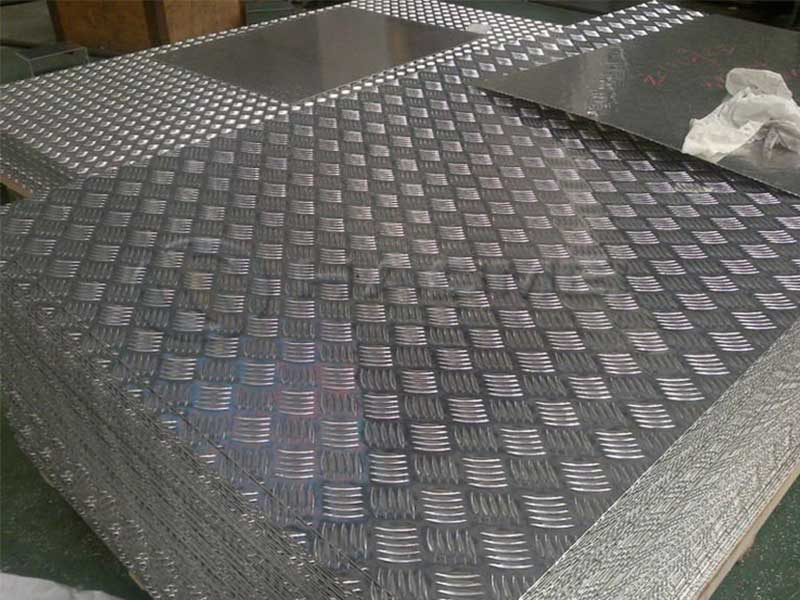

Embossed aluminum sheets with deep drawing capabilities in alloys 1050 and 1060 are widely recognized for their outstanding combination of excellent surface finish, flexibility, and formability. These materials are essential in multiple industrial and consumer applications due to their corrosion resistance, ductility, and excellent aesthetic appeal following embossing.

Embossed aluminum sheets, particularly molded from 1050 and 1060 alloys, feature a textured surface created by rolling patterns that improve aesthetic quality and functional properties such as deeper forming ability during deep drawing. The mill finish represents the original smooth or slightly matte finish from the rolling process prior to further surface treatments.

These alloys are in the 1000 series of pure aluminum, boasting high aluminum content — at least 99.5% for 1050 and 99.6% for 1060 alloy — providing excellent corrosion resistance, thermal, and electrical conductivity.

2. Features

- Excellent Deep Drawing Capability: Suitable for complex, hollow, and intricate shape components.

- Corrosion Resistance: Rust-proof, suitable for both indoor and outdoor uses.

- Lightweight: Easy handling and cost-effective transport.

- Mill Finish Surface: Prime material for diverse secondary finishing such as anodizing or painting.

- High Reflectance and Heat Conductivity: Perfect for lighting industries and heat dissipating applications.

- Decorative Appeal: Pattern embossing increases non-slip properties and visual attractiveness.

3. Chemical Composition

| Element | 1050 Alloy (%) | 1060 Alloy (%) |

|---|

| Aluminum (Al) | 99.5 min | 99.6 min |

| Iron (Fe) | 0.40 max | 0.30 max |

| Copper (Cu) | 0.05 max | 0.03 max |

| Manganese (Mn) | 0.05 max | 0.03 max |

| Silicon (Si) | 0.25 max | 0.25 max |

| Zinc (Zn) | 0.05 max | 0.05 max |

| Others | 0.03 max together | 0.03 max together |

4. Mechanical Properties

| Parameter | 1050 Alloy | 1060 Alloy |

|---|

| Tensile Strength (MPa) | 70 - 110 | 70 - 125 |

| Yield Strength (MPa) | 30 - 60 | 40 - 70 |

| Elongation (%) | 15 - 35 (annealed) | 18 - 32 (annealed) |

| Hardness (HV) | 30 - 40 | 30 - 45 |

| Density (g/cm³) | 2.70 | 2.70 |

5. Technical Specifications

| Specification | Details |

|---|

| Thickness Range | 0.2 mm to 3.0 mm |

| Sheet Width | 1000 mm – 2000 mm |

| Manufacturing Process | Hot rolling & Cold rolling |

| Surface Finish | Mill finish prior to embossing |

| Embossing Patterns | Embossed diamond, ribbed, pyramidal |

| Tolerance on thickness | ±0.03 mm |

| Flatness | Within 1 mm/m |

6. Performance Characteristics

| Aspect | Description | Output/Value |

|---|

| Formability | Excellent deep-drawing capacity | Minimize risk of cracking |

| Corrosion Resistance | High — More than many alloys | Ideal for harsh environments |

| Surface Durability | Improved with embossing pattern | Scratch & slip-resistant surface |

| Thermal Conductivity | ~220 W/m·K | High-efficiency heat conduction |

| Workability | Easy welding, bending, machining | Supports wide manufacturing |

7. Typical Applications

- Kitchen Appliances: Cooking pots, trays, ovens that require hygienic non-reactive surfaces.

- Architectural Panels: Decorative wall cladding, ceilings benefiting from corrosion resistance and stylish finish.

- Transportation: Lightweight vehicle panels, ceiling linings.

- Electrical Components: Heat sinks, reflectors for lighting.

- Consumer Goods: Luggage, suitcases, cases where durable, scratch-resistant surface is key.

- Food & Beverage Packaging: Containers and cans due to non-toxic and corrosion resistant nature.

| Benefit | Explanation |

|---|

| Corrosion Resistance | Long service life due to natural oxide-layer withstanding rust and chemical attacks |

| Excellent Finish | Mill finish facilitates both functionality and decorator-friendly surface for various industries |

| Deep Drawing & Formability | Ideal for complex shaped product manufacture, limiting waste and maximizing economics |

| Lightweight | Reduced transport and operational costs |

| Cost Effective | Pure alloy grade with mill finish offers affordability combined with strong specs |

1050

1060

https://www.aluminum-sheet-metal.com/a/embossed-aluminum-sheet-deep-drawing-1050-1060-mill-finish.html

Related Products

Related Blog