In the realm of printing technology, a unique product has caused every print house to take notice—the blue color offset CTP (Computer-to-Plate) aluminum printing plate. While it may bear the same fundamental characteristics as its counterparts, its striking azure hue represents a leap in visual and operational efficiency.

What is a CTP Aluminum Printing Plate?

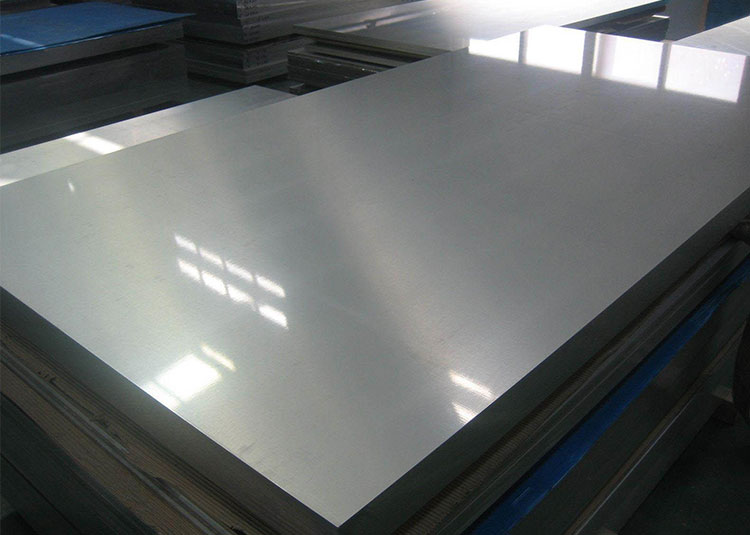

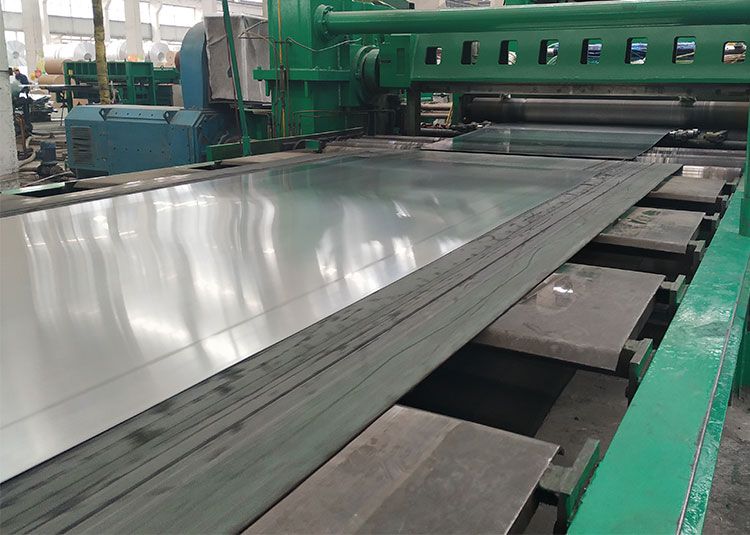

The concept of Computer-to-Plate (CTP) is straightforward—a specific technology that allows printed images to be generated directly from digital files without the preceding steps of film processing. An aluminum printing plate serves as the medium onto which ink begins to transfer and is fundamental for offset printing, widely used in high-volume production.

The blue color logic ties back to functionalities rather than aesthetics—combined with certain chemical coatings, the blue hue has properties inhibiting scratches and enhancing the depiction of quality on press.

Parameters of the Blue Offset CTP Aluminum Printing Plate

When considering any CTP product, specifically the blue offset aluminum plate, certain technical parameters come into play:

| Parameter | Specification |

|---|---|

| Surface Coating | Blue radiation-sensitive coating |

| Alloy Composition | Al 1050H14/8006 |

| Thickness | 0.15 – 0.30 mm |

| Thermal Sensitivity | Peak at 830 nm |

| Plate Dimensions | Various (Standard = 1200 x 900 mm) |

| Grain Type | Fine-mixed pattern |

| Printing Volume Potential | Up to 100,000 impressions |

Alloy tempering predominantly leaning towards 1050 ensures a combination of flexibility and durability, defining the core identity of the blue CTP aluminum plate.

Implementation Standards

While technical specifications lay a strong foundation, implementation standards guild businesses toward uniform industry practices. The blue color offset printing plates comply with:

- ISO 12647 - Focused on standard specifications and control for the regularity of color print quality.

- ANSI/ ITSDF 19B - Addressing health and safety guidelines.

- SWOP (Specifications Web Offset Publications) – Ensuring it meets needed metrics for web press setups.

These standards reinforce adherence to global expectations, enhancing print reliability.

Quality Production: Various workflows need adjustment. It would benefit print houses to facilitate superior imaging modules to cater to CTP readings, liaising paper management and consumables.

Alloy Tempering and Chemical Properties

The aluminum alloy used in creating these plates plays a crucial role not just structurally but chemically. Expect the following attributes comprising the print efficiency and surficial protections:

| Element | Percentage Composition (%) |

|---|---|

| Aluminum (Al) | 99.50 |

| Magnesium (Mg) | 0.5 |

| Silicon (Si) | 0.15 |

| Iron (Fe) | 0.10 - 0.25 |

| Others (Cu, Zn etc.) | < 0.05 |

Creating Durability Through Properties

- Thermal additional processing ensures these CTP plates withstand both high-speed runs and volatile print environments by promoting structural integrity.

- Ionization barriers integrated into the surfaces prevent typical wear with longer lifecycle outcomes.

Looking beyond merely printing output characteristics, the conversation around eco-sustainability will bolster the blue offset CTP aluminum plate. With gentle processing setups, these plates eliminate chemical estates pertaining to film development—one steps afar from harmful chemical ethers commonly seen in stick-to-film processes. Moreover, longer plate lives significantly translate to reduced waste, providing economic relief to prints-powered suppliers.