In a world where medical advancements constantly push the boundaries of technology, ensuring the integrity of pharmaceutical products isn’t just important; it's crucial. At the forefront of this innovation lies aluminum foil with enhanced oxygen and moisture barrier properties, representing a transformative structural solution for medicine packaging.

the Need for Enhanced Packaging

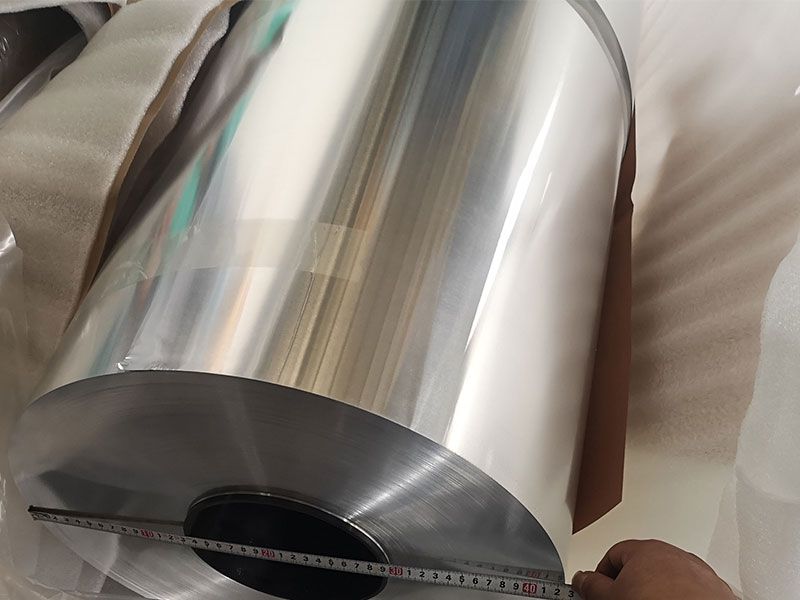

Pharmaceutical products are highly sensitive to exposure to oxygen and moisture, which can lead to degradation and reduced efficacy. Packaging plays a pivotal role in maintaining the stability and quality of medicines. Aluminum foil provides an inherent barrier against these two significant foes. However, with advancements in alloy formulations, it now offers a significantly enhanced reaction.

- Chemical Unreactivity: Aluminum foil inherently resists reaction with most medicinal compounds, ensuring your product remains untouched by metal leaching.

- Non-Toxic Properties: Usability in pharmaceutical applications is complemented by increased safety for patients.

The Technical Landscape: Parameters And Implementation Standards

In order to develop reliable aluminum foil solutions for medicine packaging, it is vital to comprehend several technical parameters dictated by international implementation standards. Here's a clear table breaking down these fundamentals:

| Parameter | Specification |

|---|---|

| Alloy Composition | Al 80% or above |

| Temper | O, H14, H18 |

| Thickness | 20-200 µm (millimeters) |

| Oxygen Barrier (mv/100 in²/24 hrs) | < 0.10 |

| Moisture Barrier (g/100 in²/24 hrs) | < 0.1 |

| Wettability (dyne/cm) | 40-60 |

| Heat Sealable Protocols | Complies with ISO 11607 |

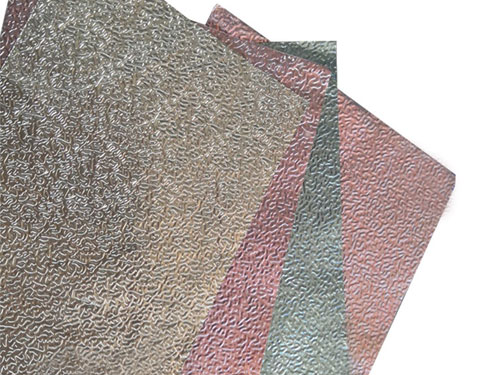

| Surface Finish Requirement | Smooth/Coated |

| Chemical properties (per ASTM) | Complies to ASTM B92-96 |

these parameters ensures compliance with regulations while optimizing packaging performance.

Alloy Tempering and Chemical Property Detailing

The aluminum industry's answer to pharmaceutical adaptability flows through the tempering process. Each temper's characteristics provide specific benefits crucial for packaging pharmaceuticals:

- O Temper (Annealed): Ideal for flexibility and process facilitation during packaging sealed pouches. Elastic yet strong.

- H14 Temper (Half-Hard): Provides a middle ground of strength and workability, especially beneficial in secondary retorts.

- H18 Temper (Hard): Superior mechanical strength and puncture-resistant attributes make it appropriate for primary packages facing smashing or crushing.

Each tempered solution has been rigorously evaluated in distinctive tests ensuring both properties align with the demanding needs of pharmaceutical directors enforcing safety rails on packaging materials while maintaining their morals regarding environmentally-friendly products.

The Environmental Equation: Sustainability Meets Effectivity

Apart from listening to the voice of compliance, our minds gear towards how pharmaceutical packaging elevates sustainability standards without combatting safety. Aluminum packaging is 100% recyclable with virtually zero residual energy, bringing sustainable manufacturing processes into alignment with core business aims within the pharmaceutical distribution lifespan.