Comprehensive Guide to 1100 H14 Metal Alloy Aluminium Sheet: Functions, Applications, and Parameters

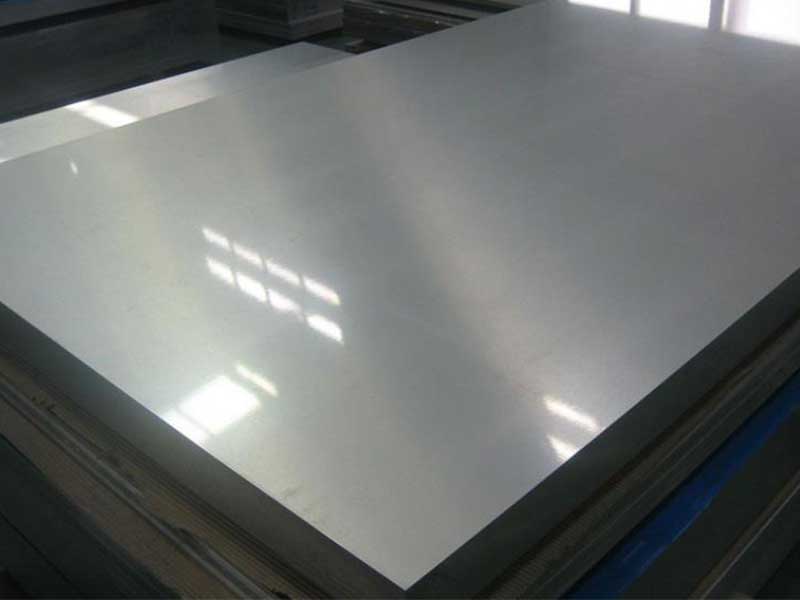

Aluminum has long been treasured in various industries due to its lightweight strength, resistance to corrosion, and versatility. Among its various alloys, the 1100 H14 metal alloy stands out as an exemplary choice for numerous applications.

1100 H14 Metal Alloy Aluminium Height

The 1100 alloy series is categorized as commercially pure aluminum, typically containing at least 99% aluminum. Its H14 temperament indicates a strain-hardened version, granting it a robust balance of formability and accepts non-intensive applications. This strain-hardening enhances its mechanical properties without involving any major chemical alterations. Now, let's extract the essential details about 1100 H14 aluminum from a scientific perspective.

| Chemical Property | Element | Composition % |

|---|---|---|

| Aluminum (Al) | Carbon | 99.0% min |

| Iron (Fe) | Trace element | 0.7% max |

| Silicon (Si) | Alloying element | 0.4% max |

| Copper (Cu) | Trace element | 0.05% max |

| Manganese (Mn) | Grain refiner | 0.1% max |

| Magnesium (Mg) | Not present | 0% |

| Zinc (Zn) | Trace element | 0.1% max |

Parameters for 1100 H14 Metal Alloy Aluminium Sheet

Thickness: Typically ranges from 0.2mm to 0.5mm, adjustable based on manufacturing mechanics to fit specific operational needs.

Width: Sheets might approach widths ranging from 1000 mm to larger rolls depending on processing demands.

Yield Strength: Stands approximately at 110 - 155 MPa (Megapascals), emphasizing the enhanced durability despite its pure aluminum trance.

Ultimate Tensile Strength: Seen afloat from 115 - 175 MPa, indicating a commendable resilience before failure.

Elongation at Break: Approximately 3% - 20%, highlighting its excellent workability particularly woven in the realm of delicate forming processes.

Functional Attributes of 1100 H14 Aluminium Sheets

The 1100 H14 aluminum sheets exhibit various functional attributes owing to their mechanical tensile properties and lower density:

Excellent Corrosion Resistance: in environments exposed to moisture and corrosive surroundings such as chemical processing and marine applications, promoting longevity.

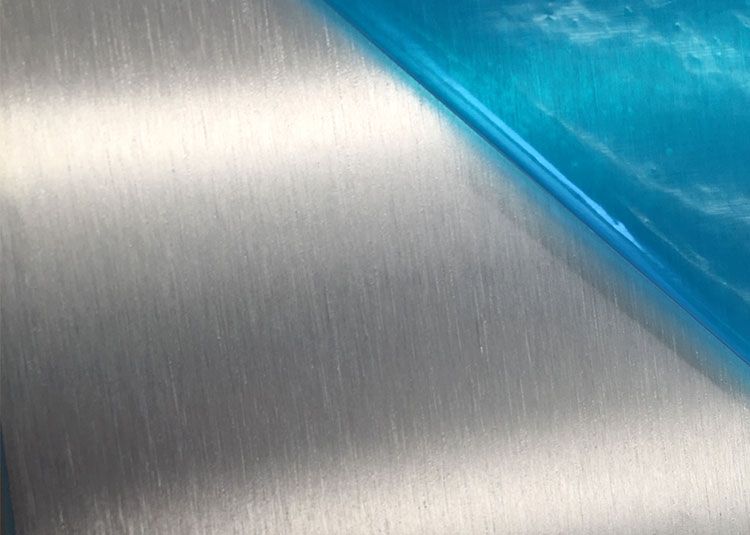

Formability and Workability: Requires lesser brute force to shape, malleable enough for bending, laser cutting, and riveting, making it of great significance in domestic utensils and food packaging.

Thermal and Electrical Conductivity: Very high thermal and electrical conductivity makes it ideal for electrical applications.

Applications Across Industries

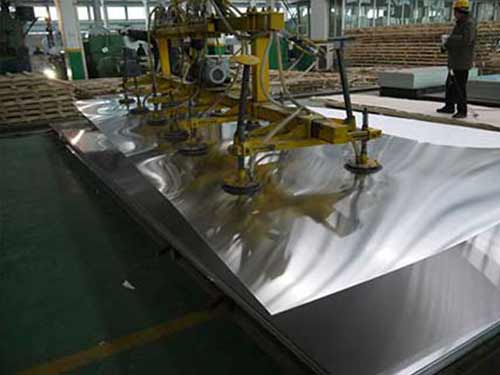

The functionally robust calculations extend the realm of application toward multiple performances:

Aerospace: Components and thermal protection where portions must endure temperature inconsistency, such as parts of heat shields.

Automotive: Perfectly used in fuel tanks and frames that require overlapping between lightweight strengths and proper energy absorptions on impact.

Food and Medical: As 1100 aluminum doesn't alter the taste of the food wrapped or shelf life when applied in food industries, it circulates even through various medical storage units ensuring compliance with health regulations.

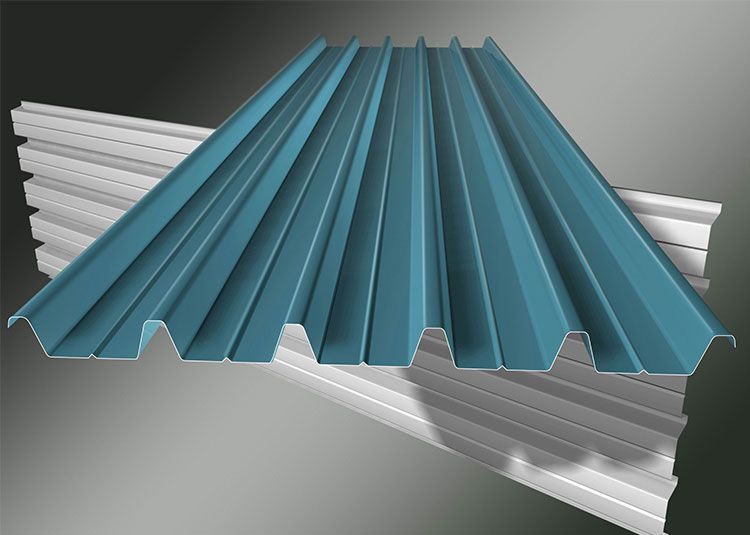

Construction and Building: Rigid but graceful in a construction endeavor, particularly in roofing sheets offering enhanced resistance to climatic factors without abstract deviations.

Industry Standards and Implementation

In coherence with global benchmarks, the 1100 H14 aluminum substrate encompasses compliance with:

American Society for Testing and Materials (ASTM): Such as ASTM B209, verifying performance standards across defined thickness ranges whilst ensuring a measured dynamic strength.

The International Organization for Standardization (ISO) rather credits standardized shopping across sheets followed at meticulous manufacturing.

Heat Treatment and Tempering

Unlike other aluminum alloys requiring profiling upfront, 1100 reflects tempering implicitly:

- It embraces no significant heat treatment processes for elemental work-hardening based manifestations that slump upward with cerebral strategic cold working maneuvers exposing amplified strength rewarded through metallurgical formations documented.