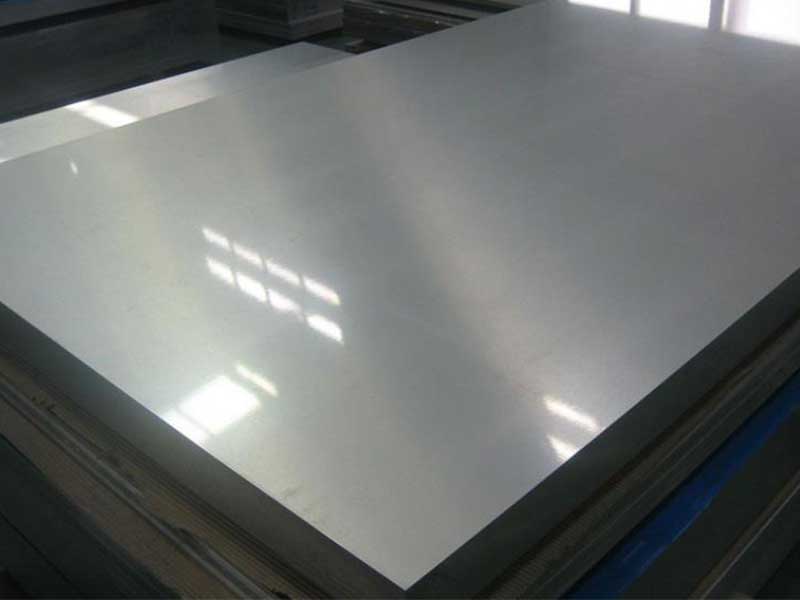

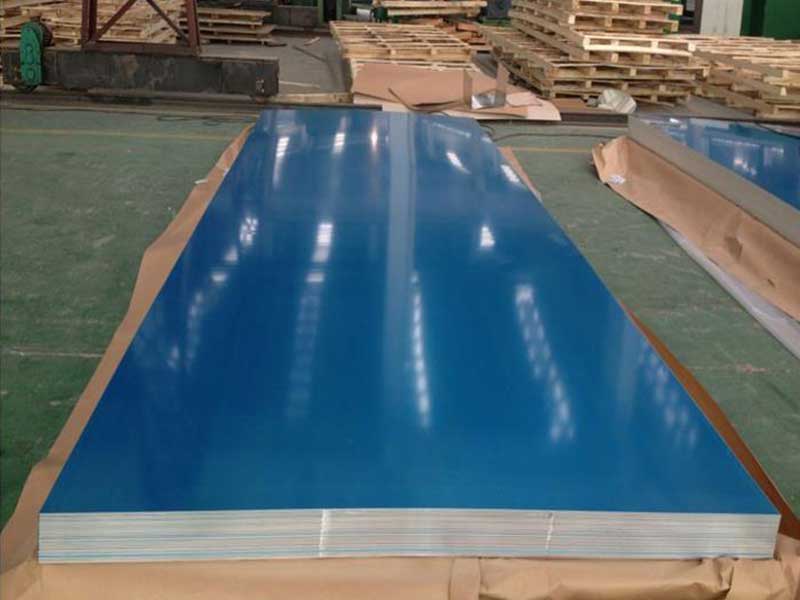

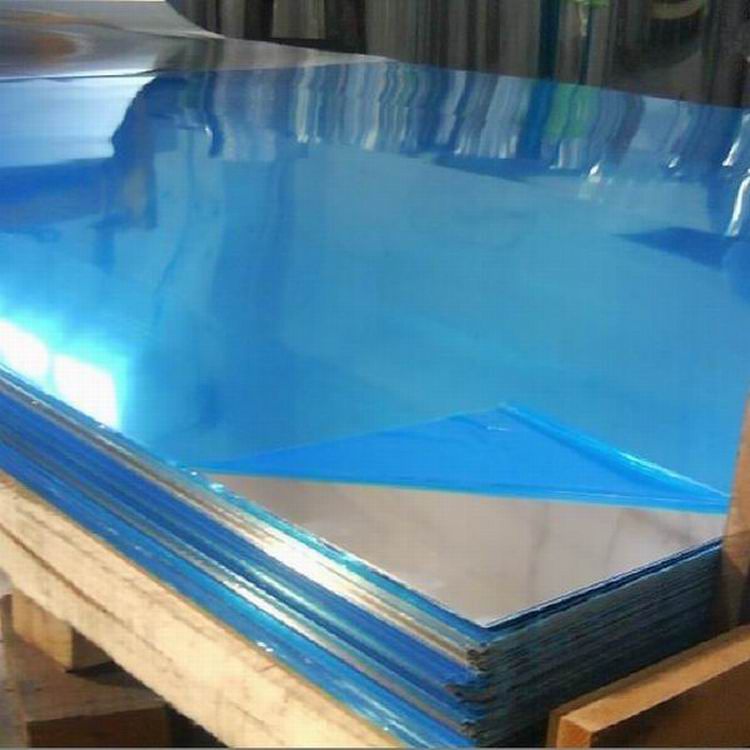

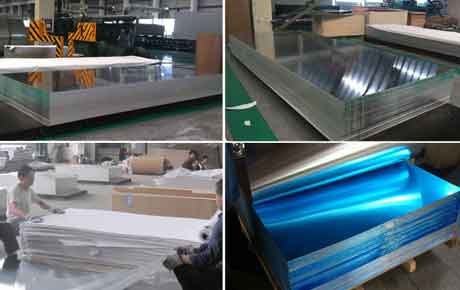

Plain Aluminium Sheet 1100 1050 H14 is an industrial-grade aluminum product widely recognized for its chemical composition, superior mechanical properties, and versatility in a range of applications. This alloy, characterized by excellent corrosion resistance, remarkable formability, and lightweight features, serves as an ideal choice for diverse industries such as construction, automotive, and culinary equipment.

Features

- Lightweight: Aluminum offers high strength-to-weight ratio, making it suitable for applications where reducing weight is crucial.

- Corrosion Resistance: Holds up well in harsh environments due to its ability to resist oxidation and corrosion.

- Excellent Formability: The H14 temper ensures that the sheet is strong yet can be easily manipulated to fit different forms.

- Good Thermal Conductivity and Electrical Conductivity: Well-suited for heat exchangers and electrical applications.

- Recyclable: 1100 and 1050 alloys are 100% recyclable, contributing to environmentally-friendly practices.

Applications

The following are some common applications of Plain Aluminium Sheet 1100 1050 H14:

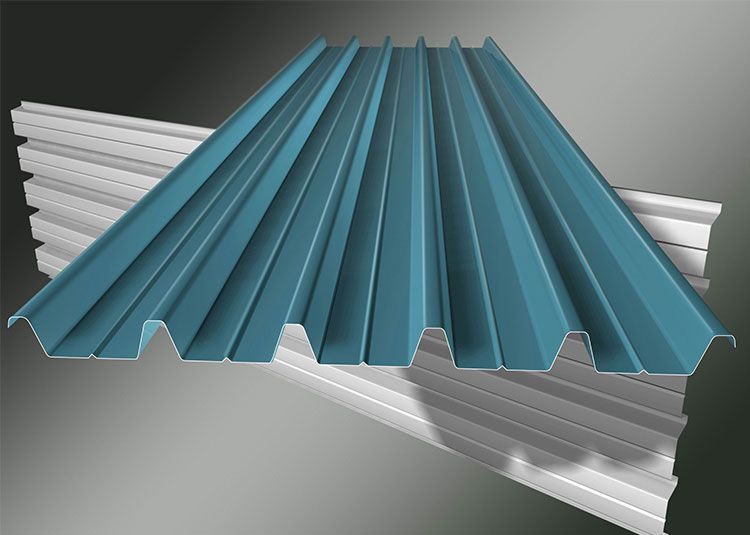

- Construction: Wall panels, roof cladding, and interior ceilings.

- Food Industry: Cookware, food processing, and packaging equipment.

- Electrical: Faceplates, electrical confinement, and conduits.

- Automotive: Body panels and engine components.

Technical Specifications

| Property | Value |

|---|---|

| Alloy | 1100, 1050 |

| Temper | H14 |

| Thickness Range | 0.2 mm - 25 mm |

| Width | Up to 1500 mm |

| Length | Custom lengths up to 6000 mm |

| Density | 2.70 g/cm³ |

| Yield Strength | 125 MPa (min) |

| Ultimate Tensile Strength | 170 MPa (min) |

| Elongation | 15% (min) |

| Modulus of Elasticity | 69 GPa |

| Electrical Conductivity | 60% IACS out of 100% based on copper |

| Thermal Conductivity | 210 W/mK |

Chemical Composition

The chemical composition for Plain Aluminium Sheet 1100 1050 H14 is provided below. The composition values might vary slightly depending on the manufacturer:

| Element | Min (%) | Max (%) |

|---|---|---|

| Aluminium | 99.0 | Bal. |

| Iron | 0.0 | 0.7 |

| Silicon | 0.0 | 0.25 |

| Copper | 0.0 | 0.05 |

| Manganese | 0.0 | 0.05 |

| Magnesium | 0.0 | 0.1 |

| Chromium | 0.0 | 0.1 |

| Zinc | 0.0 | 0.1 |

| Titanium | 0.0 | 0.05 |

Tempering Conditions

H14 tempering enhances the strength properties of aluminum through deformation. The H14 designation indicates the following:

- H: Strain-hardened

- 14: Indicates the level of strain hardening involved to achieve semi-hard status.

| Temper | Typical Yield Strength (MPa) | Range of Hardness (Brinell) |

|---|---|---|

| H14 | 125 | 50 - 60 |