Custom Aluminum PVC Blister Packaging is essential for pharmaceutical applications, offering a combination of convenience, safety, and efficacy in protecting tablets and capsules.

Functions of Blister Packaging

- Protection: Blister packaging shields products from moisture, light, and contaminants, ensuring the integrity and efficacy of the pharmaceuticals.

- Easy Access: Designed for patient-friendly access, blister packs allow consumers to easily dispense single doses without compromising other tablets or capsules.

- Product Management: By displaying tablets or capsules effectively, manufacturers can enhance product visibility and consumer awareness.

- Counterfeit Prevention: Custom blister packaging includes unique designs and formats that can act as security features to deter counterfeiting.

Applications

Blister packaging is profoundly employed in various sectors, with a heavy emphasis on the pharmaceutical industry. Common applications include:

- Tablets and Pills: Protection and convenience in administration.

- Capsules: Preserving the contents of bulk and soft gel capsules from degradation.

- Nutraceuticals: Seed formulations, vitamins, and supplement packaging.

Technical Specifications

Parameters and Standards

To ensure optimal performance, the specifications of Custom Aluminum PVC Blister Packaging include certain parameters, along with compliance with prominent World Health Organization (WHO) standards for pharmaceutical packaging.

| Parameter | Description |

|---|---|

| Material | Hard PVC, Aluminum Foil |

| Thickness | PVC: 0.15-0.3 mm, Aluminum: 20-60 μm |

| Chemical Resistance | Resistant to most chemicals and pierce resistant |

| Heat Seal Temperature | 130-220 °C |

| Moulding Process | Thermoforming/Cold-forming |

Chemical Properties

| Property | Value |

|---|---|

| Density | PVC: 1.4 g/cm³, Aluminum: 2.7 g/cm³ |

| Moisture Absorption | <0.1% (must ensure packaging integrity) |

| UV Protection | Average 95% UV light soaking resistance |

| Barrier Effectiveness | O2 permeability: <5 cm³/m²/24h |

Description of Materials Used

- PVC: Known for its flexibility and toughness, PVC offers excellent barrier properties against moisture while being cost-effective.

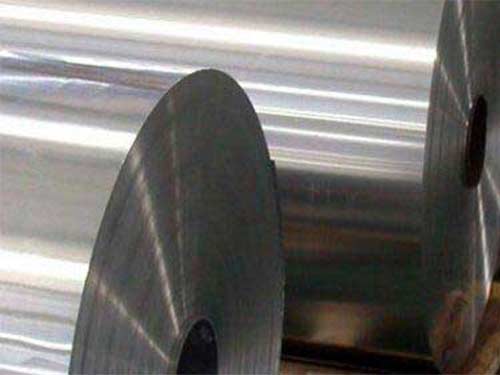

- Aluminum Foil: Provides excellent barrier properties against light, oxygen, and microorganisms hence elongating product's shelf life.

Alloy Tempering Conditions

Aluminum used in blister packaging typically falls under specific alloy tempering specifications to maintain its mechanical integrity:

| Aluminum Alloy | Temper Condition | Specification |

|---|---|---|

| 8011 | O (Soft) | Anti-tearing and fading when exposed to moisture |

| 8011 | H18 (Hard) | Increases tensile strength, ideal for busier environments and rough handling |

Advantages of Custom Aluminum PVC Blister Packaging

- Versatile Design Options: Custom options accommodate any product according to brand identity.

- Transparent Visuals: The see-through quality of PVC allows clear product visibility for consumers.

- Cost-effective: Materials are budget-friendly, providing solid ROI in largescale manufacturing whilst upholding compliance regulations.

Implementation Tips

- Choose the Right Materials: It is essential to take the product's chemical nature into account to choose materials and coatings that reduce cross-reactivity.

- Test and Evaluate: Conduct stability testing to evaluate the physical and chemical durability under predicted shelf life timelines.

- Maintain Design Consistency: Limit dietary supplements overlaps which increases exit-point vulnerabilities adding complexities in harvesting customization blends.