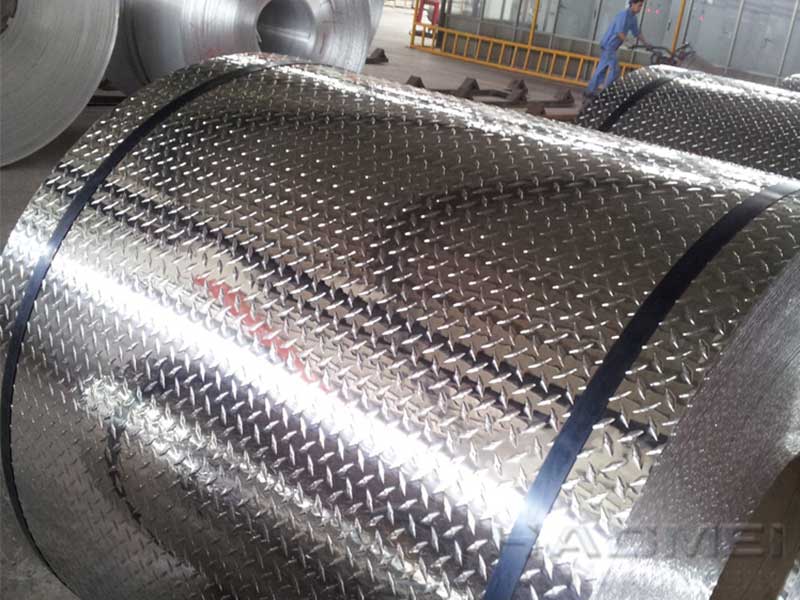

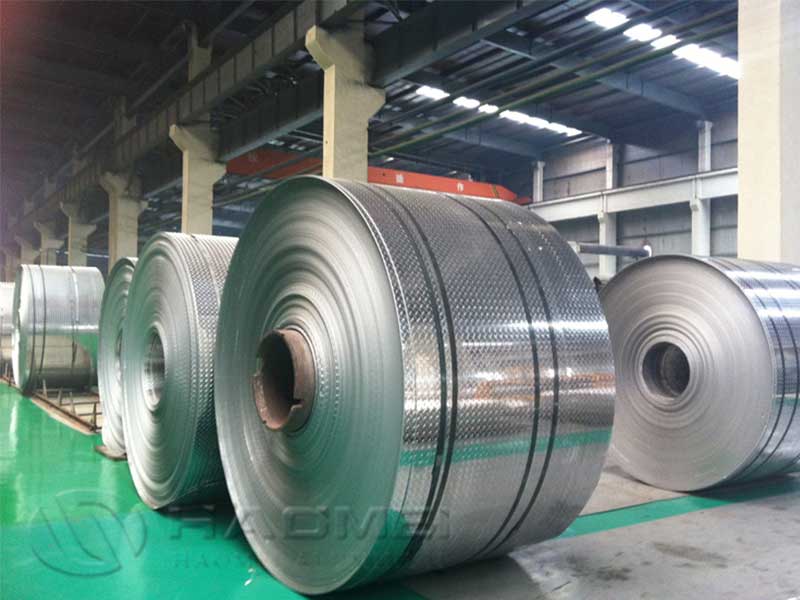

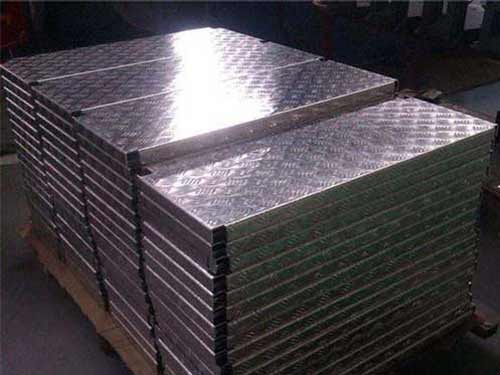

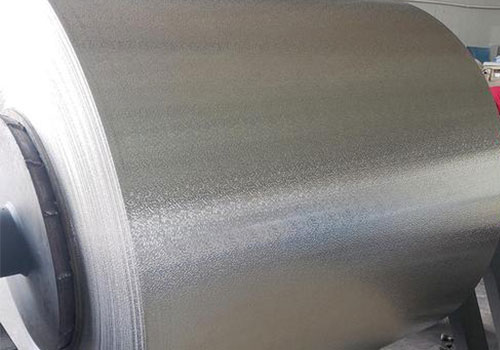

Diamond aluminum checkered plate (also known as tread plate or non-slip sheet) is a crucial material in various industries, valued for its strength, durability, and anti-slip properties.

Functions of Diamond Aluminum Checkered Plate

The primary functions of diamond aluminum checkered plate include:

- Anti-Slip Surface: The diamond pattern provides an effective non-slip surface, making it ideal for walkways, ramps, and industrial flooring.

- Weight Reduction: Aluminum's lightweight nature helps in reducing overall weight without sacrificing strength, making it suitable for applications that require superior weight-to-strength ratios.

- Corrosion Resistance: Resistant to rust and corrosion when exposed to atmospheric conditions, thereby increasing its longevity and reducing maintenance tales.

- Aesthetic Appeal: The shiny finish adds aesthetic value in architectural applications, enhancing the visual elements of a structure.

Applications of Diamond Aluminum Checkered Plate

Diamond aluminum checkered plate has various applications across multiple sectors:

- Construction: Floors, wall cladding, steps, and platforms due to its non-slip properties.

- Marine Industry: Used in boats and ships to provide secure walking surfaces that endure harsh conditions.

- Automotive: Applications in vehicle interiors, trucks, trailers, and cargo area platforms.

- Manufacturing: Heavy-duty equipment protection and ramp access in manufacturing plants and warehouses.

- Household: Furniture and small home appliances often incorporate it for decor, providing both practicality and style.

Technical Specifications

The technical prowess of a diamond aluminum checkered plate should not be understated. Below are the fundamental technical specifications of these products.

Technical Parameters

| Property | Specification |

|---|---|

| Material | Aluminum |

| Thickness | 1.0 mm to 8.0 mm |

| Width | 1,000 mm to 2,200 mm |

| Length | Cut to size |

| Pattern Height / Depth | 0.5 mm to 1.5 mm |

| Alloy Types | 1050, 1060, 5754, 5083 |

| Temper | H14, H16, H18, H24 |

Implementation Standards

Diamond aluminum checkered plates adhere to the following standards:

- ASTM B209 - Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- EN 485/2 - European Standard for Aluminum Sheets.

- JIS H 4000 - Japanese Industrial Standard.

Alloy Composition and Tempering Conditions

Choosing the right alloy and tempering condition is vital for specific applications. Below is the chemical composition of commonly used alloys.

Chemical Composition of Common Alloys

| Alloy | Chemical Composition (%) |

|---|---|

| 1050 | Al ≥ 99.5 %, Fe ≤ 0.4 %, Si ≤ 0.25 % |

| 1060 | Al ≥ 99.6 %, Fe ≤ 0.3 %, Si ≤ 0.25 % |

| 5754 | Mg 3.0-4.5 %, Mn 0.2-1.0 %, Si ≤ 0.4 % |

| 5083 | Mg 3.0-4.5 %, Mn 0.4-0.9 %, Si ≤ 0.4 % |

Tempering Conditions

The tempering conditions influence the mechanical properties and workability as below:

| Alloy | Temper | Conditions |

|---|---|---|

| 1050 | H14 | Strain hardening + 1/2 anneal |

| 1060 | H16 | Strain hardening + 1/4 anneal |

| 5754 | H24 | Strain hardening + full anneal |

| 5083 | H321 | Aged rolled after solution treatment (high strength) |