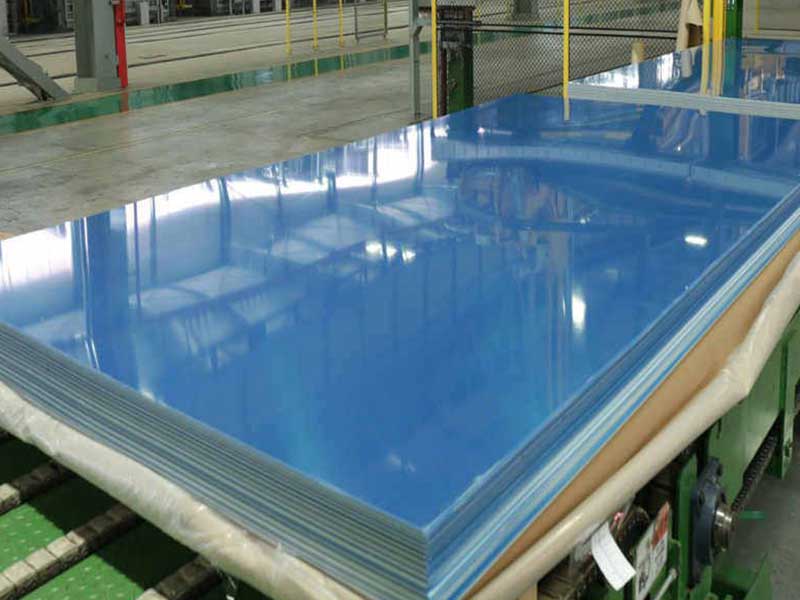

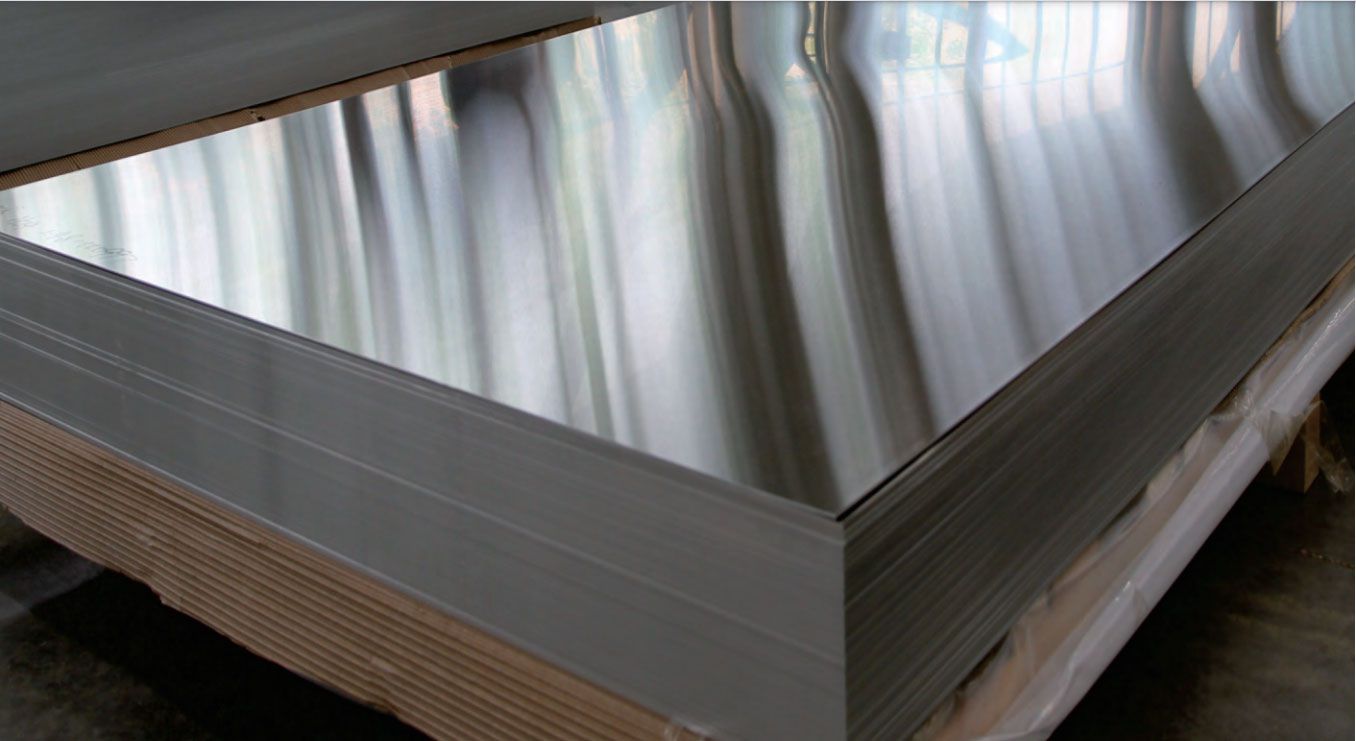

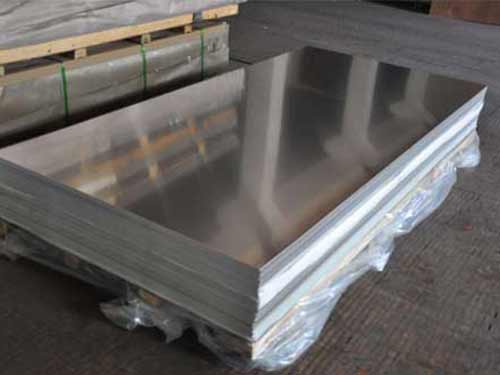

In the realm of modern electronics, the materials used play a pivotal role in ensuring optimal performance, sustainability, and functionality. Among these materials, aluminum sheet plates hold a vibrant significance. Their lightweight nature combined with thermal properties makes them an excellent choice for various applications in electronic devices such as casings, heat sinks, and structural bodies.

Unique Characteristics of Aluminum Sheet Plates

Close your eyes for a second and imagine a bustling electronics manufacturing facility nestled in the heart of innovation. The unmistakable buzz of machinery reinforces a unanimous belief: quality begins with choosing the right material. Among such materials, aluminum speaks out as a dedicated partner for electronic solutions, revered for:

- Lightweight Composition: Being around one-third the weight of steel while offering considerable strength, they create sleek designs without compromising durability.

- Mechanical Stability: These plates serve efficiently under varying impact forces and provide resilience across different conditions.

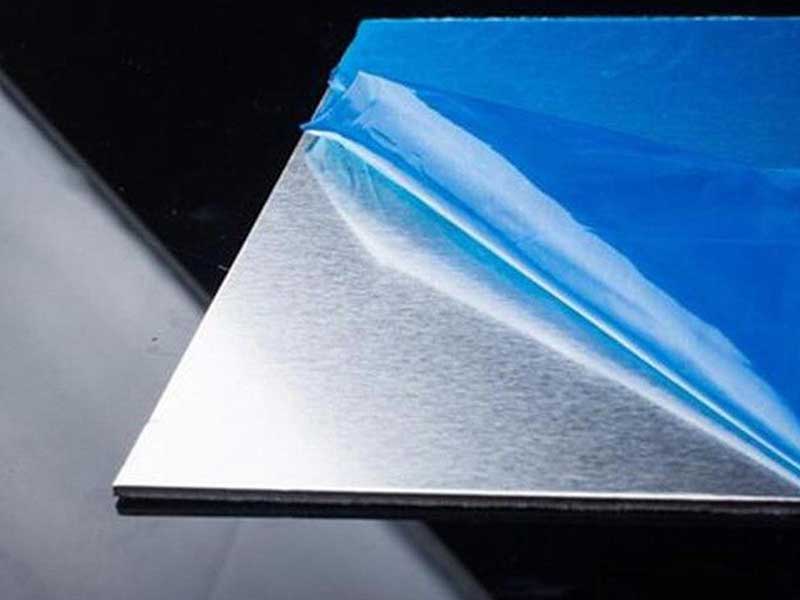

- Corrrosion Resistance: Naturally occurring, tough oxide films give aluminum an enviable resistance to oxidation and corrosion which is crucial in lengthy keynote product lifecycles.

- Thermal & Electrical Conductivity: High electrical and thermal conductivities ensure components maintain optimal temperatures preventing damage.

Specifications

the technical details associated with aluminum sheet plates allows electronics decision-makers to not only choose the right products but to dictate how efficiently these materials will perform in real-world applications.

Parameters

- Thickness Options: Aluminum plates can be available in thicknesses from 0.6 mm to several centimeters, catering to specific needs based on ruggedness and designs.

- Widths & Lengths: Standard sizes may vary; plates can span in widths of 36 to 48 inches and lengths appropriate for end applications - often up to 120 inches.

- Density: Typically features a density of about 2.7 g/cm³, ensuring lightweight efficiency facilitative for better handling and assembly during manufacturing processes.

Implementation Standards

Aluminum sheets for the electronics industry typically must comply with various standards to ensure reliability and consistency. Commonly relied-upon standards include:

- ASTM B209: This specification covers flat-rolled aluminum and aluminum alloy (sheet) products that cater to the specified structural applications in circles from automotive to electrical frameworks.

- ISO 9001: Certification of Quality management, ensuring high reliability in production processes resonates deeply in electronics industries from various viewpoints.

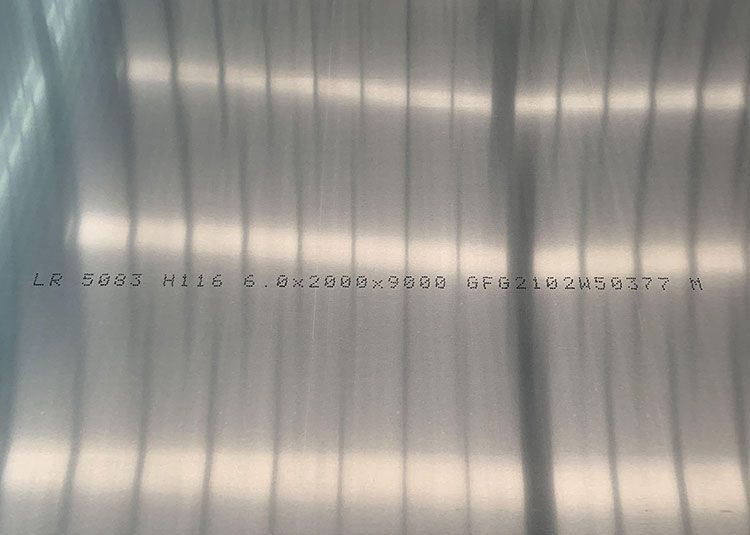

Alloy and Tempering Conditions

One unique aspect of aluminum sheets is the classification available in various alloys.

Some common aluminum alloys alongside their tempering descriptions.

| Alloy | Composition | Common Use | Tempering |

|---|---|---|---|

| 1060 | 99.6% Aluminum | Vending maching housing components | O (annealed), H (Strain hardened) |

| 2024 | 90.7%-94.7% Aluminum with Copper | Aerospace elements | T3 (Solution Htilization, Aging) |

| 3003 | Manganese (around 1.0%) | Insulating decorations | H14 (cold worked, half-hardening) |

| 5052 | 2.2%-2.8% magnesium | Marine components | H32 (Cold-Hail Ability in conformity) |

Chemical Properties: Maximizing Effectiveness

Recognizing the importance of durability and corrosion resistance, brands face a Guaranteed assurance with aluminum delineations, such as:

Johnsen's ASTM analysis largely affirms aluminum’s excellent performance against harmful environmental parameters such as pH less than 4 and greater than 9.

Its affinity for cobalt, chromium further highlights that devices will stand the test for completed formation insulating happiness to electronics based all around sought/customer-ready visualization circuits.