In the refrigeration industry, material choice significantly impacts the performance, durability, and energy efficiency of freezer units. Among the top materials embraced today is the Embossed Aluminum Sheet Coil for Freezer, which comes with distinctive functional advantages and technical properties optimized specifically for low-temperature environments.

Embossed Aluminum Sheet Coil for Freezer

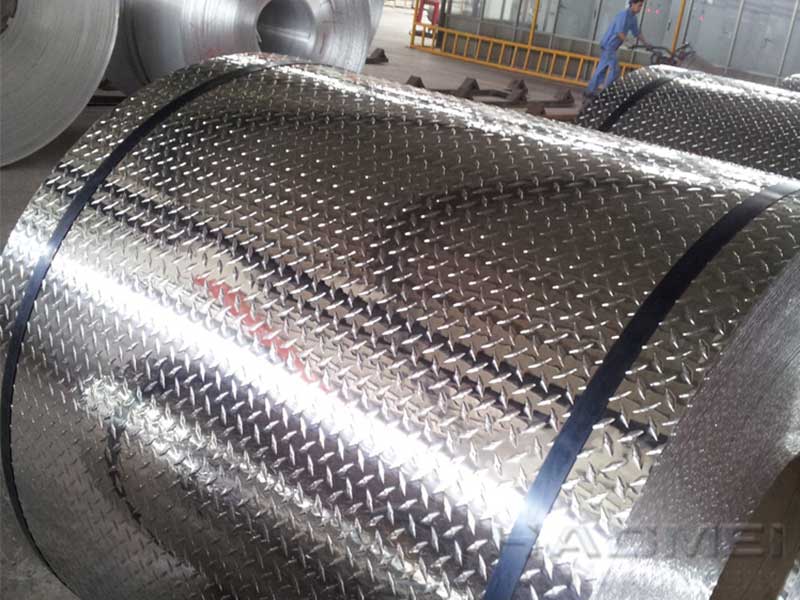

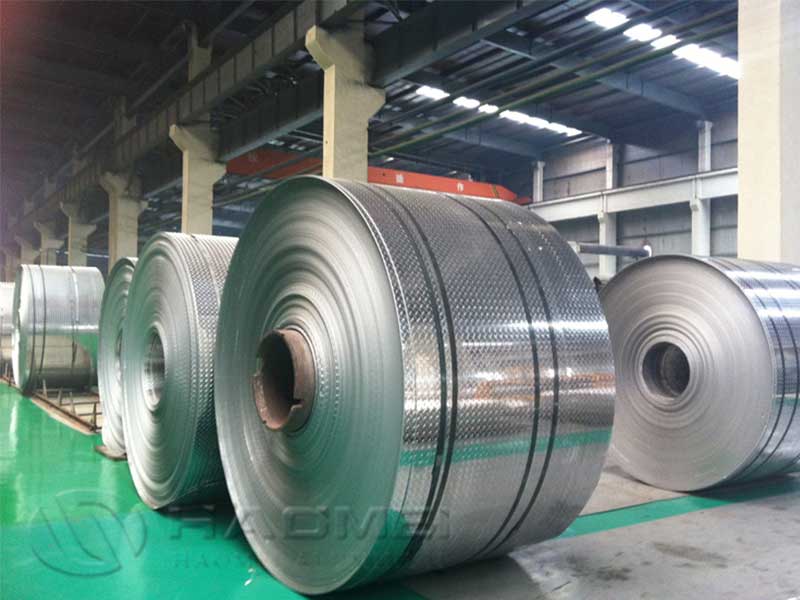

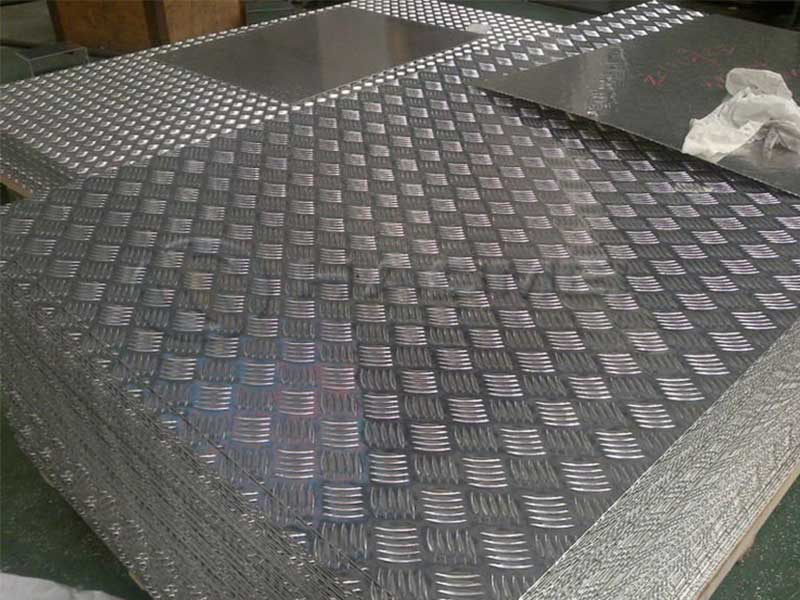

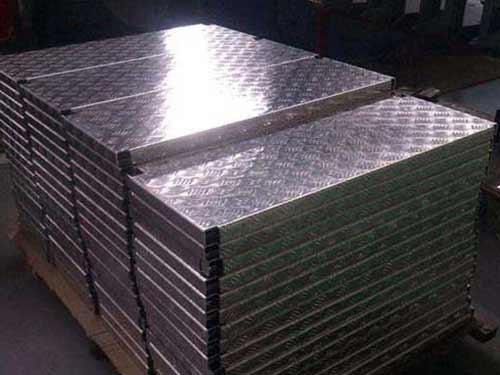

An embossed aluminum sheet coil features a textured surface finish created through a rolling process, imprinting patterns such as stucco or diamond shapes onto its surface. This texturing enhances the coil’s mechanical strength, corrosion resistance, and aesthetic appeal. When specially engineered for freezer applications, these embossed aluminum coils must consistently perform in sub-zero conditions while maintaining structural integrity.

Primary Functions for Freezer Applications

Thermal Conductivity: Aluminum naturally exhibits excellent thermal conductivity (~205 W/mK), offering efficient heat exchange vital for refrigeration units to sustain low temperatures.

Corrosion Resistance: Freezers, especially industrial units, constantly encounter moisture and irregular temperature flux. Stucco embossed aluminum’s textured surface improves resistance to condensation-related corrosion and reduces the accumulation of ice or frost, enhancing longevity.

Structural Reinforcement: The embossing process enhances rigidity and prevents deformation or buckling caused by mechanical stresses or temperature variations during freeze-thaw cycles.

Ease of Maintenance: The textured pattern minimizes surface dirt adhesion and footprint of fingerprints, making cleaning and sterilization significantly easier in hygienic freezer environments.

Technical Details and Material Parameters

the material’s essential technical parameters aids in confirming its reliability for freezer use.

| Parameter | Specification |

|---|---|

| Alloy | 3003, 5052 aluminum alloys |

| Temper | H14 (1/2 hard), H18 (hard) |

| Thickness | Typically 0.15mm – 1.5mm |

| Width | 500mm – 2000mm (customizable) |

| Surface Finish | Stucco embossing (embossed pattern) |

| Tensile Strength | ~130 – 230 MPa (depending on temper) |

| Thermal Conductivity | ~205 W/mK |

| Density | 2.70 g/cm³ |

| Melting Point | 643 °C |

| Corrosion Resistance | High (due to natural aluminum oxide + embossing) |

| Elongation at break | 10% – 30% |

Alloy Design and Tempering Conditions

Two primary alloys used in embossed freezer aluminum coils are:

3003 alloy: This is an aluminum-manganese alloy noted for enhanced strength compared to pure aluminum. It has excellent corrosion resistance and formability, making it ideal when medium strength and good corrosion resistance are required.

5052 alloy: This alloy possesses magnesium as a major component, boasting even higher strength and remarkable corrosion resistance, particularly against salt and marine atmospheres – common in frigorific transportation freezers.

Both alloys undergo temper treatments significant in conferring produced coils with desired mechanical properties:

- H14 Temper: Represents half-hard temper attained through a specific amount of work hardening or cold rolling, giving a moderate balance of strength and flexibility.

- H18 Temper: Full-hard temper achieved by extensive cold rolling, used where maximum rigidity and durability are imperative.

Applicable Standards and Quality Implementation

Industry standards guide the fabrication and application of embossed aluminum sheet coils. Referenced benchmarks include:

- ASTM B209-16: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate, specifying the alloy/designations for freezers.

- EN 485 (Europe): Aluminum Sheet, Strip, and Plate – mechanical properties inspection methods.

- ROHS and REACH Compliance: Ensuring safety and environmental focus throughout the manufacturing and application lifecycle.

- In-house QC ensures consistent embossing patterns, flatness tolerances, thermal conductivity checks, and absence of surface defects meeting ISO 9001:2015 standards.

Applications of Stucco Embossed Aluminum Coil in Freezer Systems

- Commercial Freezers: Used as inner liners and outer panels where low temperature exposure and cleaning ease help maintain microbial hygiene.

- Transportation Refrigerators: Embedded in refrigerated trucks/carriers for enhanced impact resilience.

- Cold Storage Warehouses: Wall and ceiling cladding providing excellent strength and moisture shielding.

- Walk-in Freezers: Facilitating thermal insulation and mechanical durability with suface texture aiding repair compatibility.

Ultimately, embossed aluminum coils are chosen for their synthesis of strong mechanical durability, high thermal conductivity, excellent corrosion and frost resistance, and adaptable finish that excells in challenging freezer environments.