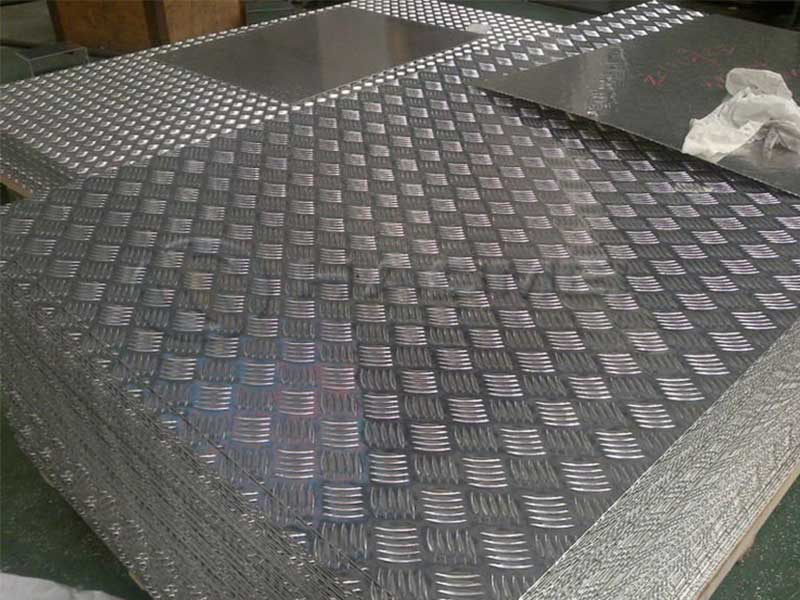

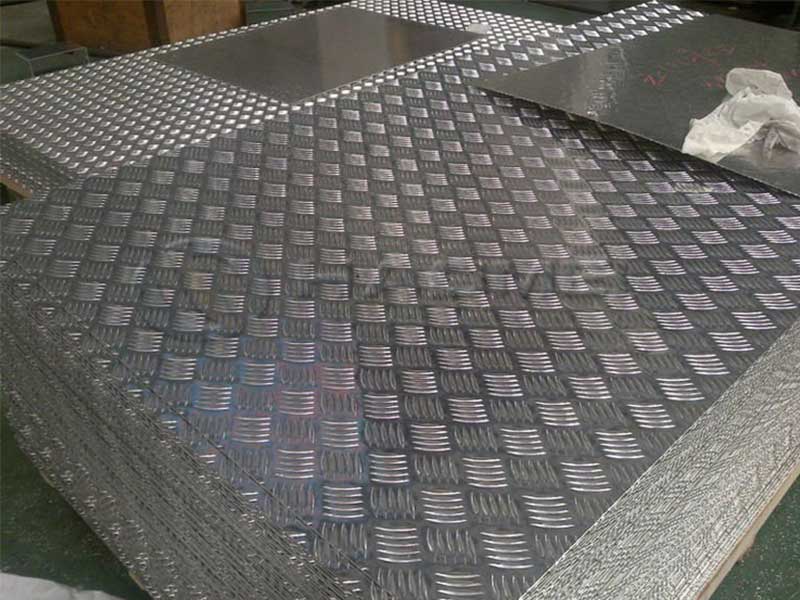

Aluminum tread plates, also known as aluminum checker plates or diamond plates, are widely used across numerous industries due to their durability, lightweight, corrosion resistance, and skid-proof surface patterns.

What is an Aluminum Tread Plate?

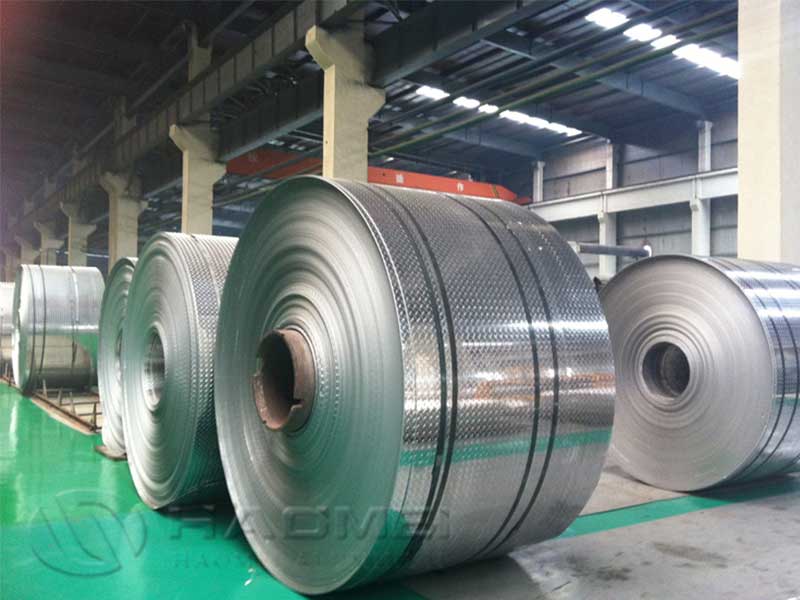

An aluminum tread plate is a thin sheet made primarily of aluminum and hot-rolled or cold-rolled with raised patterns (also called embossing) on one side to create a textured surface. These patterns are engineered to increase grip force, prevent slips, and add aesthetic value to surfaces. Aluminum envelopes the benefits of rust resistance, ductility, and ease of fabrication, making it an ideal material for tread plates.

The patterns on our aluminum tread plate aren't just cosmetic; they're a crucial part of the product's functionality. We use several, each serving a specific purpose depending on the application. The classic "diamond plate" is a workhorse – the raised diamond pattern provides excellent traction, even when wet or oily. But the depth and sharpness of those diamonds vary. A shallower pattern is good for lighter duty applications where aesthetics matter more, like truck bed liners, while the deeper, more aggressive patterns are vital for industrial flooring where heavy equipment might operate. We also produce other patterns like serrated or even custom designs for specialized projects. Personally, I find it fascinating how a simple change in the pattern’s geometry significantly impacts the product's slip resistance and overall durability.

Beyond the practical considerations, the patterns also influence the manufacturing process itself. Different patterns require different tooling in the rolling mill, necessitating careful planning and machine setup. A complex pattern means more sophisticated dies and more potential for defects. Sometimes, a seemingly minor adjustment to the die's pressure or roll speed can dramatically alter the final pattern's appearance. This has led to numerous late nights troubleshooting minor inconsistencies – you wouldn't believe the subtle variations in the diamond point angles we strive to maintain! It’s a precise balancing act between aesthetic appeal, functionality, and efficient manufacturing, and that’s what makes it both challenging and rewarding.

Common Patterns of Aluminum Tread Plates

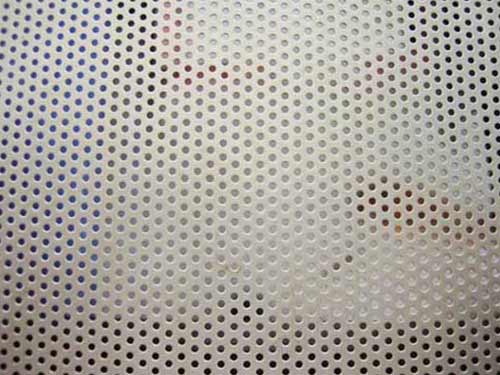

The ribbed or protruding designs on aluminum tread plates are not just random embossments—each pattern serves specific functional and decorative purposes.Below are the most popular tread plate patterns:

| Pattern Type | Description | Typical Dimensions (mm) | Distinctive Features |

|---|---|---|---|

| Checkered (Diamond) | Raised diamond shapes arranged uniformly, providing superior anti-slip properties | 3 mm to 6 mm raise | Generally used for high roughness and skid resistance toepaths, machinery flooring |

| Coin (Circular) | Small, evenly spaced circular protrusions creating a subtle texture | Diameter: 2–3 mm | Offers visually appealing texture; ideal for interiors and architectural elements |

| Raised Bars (Rib) | Parallel raised horizontal or vertical bars running in a set pattern | Bar width 4–7 mm, height 1.5–3 mm | Mainly intended for safer foot traffic with better grip, often used vehicles |

| Needle Pointed | Fine-point shaped beads in a dense grid creating microscopic friction points | Height: negligible | Provides excellent resistance with low abrasion; ideal for lifting surfaces |

| Zebra Plate | Wide-rib patterned with alternating smooth and raised stripes of varying heights | Stripes 30–50 mm wide | Combined aesthetics with anti-slip, used on vehicle footboards and industrial walkways |

Chemical Composition of Aluminum Tread Plates

Most aluminum tread plates are made from one of the following aluminum alloys, known for balancing strength, machinability, and corrosion resistance:

| Alloy | Main Components (Approx. % by weight) | Properties |

|---|---|---|

| 1000 Series (e.g., 1050, 1060) | Al minimum 99%+ | Excellent corrosion resistance, great formability, low strength |

| 3003 | Al 96.8%, Mn 1.2%, Cu 0.05%, Fe 0.7% | Good corrosion, medium strength, excellent workability |

| 5052 | Al 95%, Mg 2.5%, Cr 0.25%, Fe max. 0.4% | Very high corrosion resistance, increased strength, weldability |

| 5086 | Al 91.5%, Mg 4%, Mn 0.5%, Cr 0.1% | Marine-grade corrosion resistance with good tensile strength |

The choice of alloy significantly influences the mechanical properties suited for specific environments, from severe outdoor weather to mild interior conditions.

Features of Aluminum Tread Plate Patterns

- Anti-Slip Surface: Raised patterns significantly increase traction, making these plates ideal for pedestrian safety and vehicle applications.

- Corrosion Resistance: Aluminum alloys commonly used in tread plates resist oxidation and chemicals, suitable for indoor and outdoor installations.

- Lightweight Yet Strong: Compared to steel, aluminum plates are roughly one-third the weight yet maintain excellent strength-to-weight ratios.

- Easy Fabrication: The aluminum's typical softness allows for easy cutting, welding, (in some alloys) bending without cracking.

- Aesthetic Appeal: Tread plate patterns provide visual texture, which are used in interiors, doors, stair treads, and decorative facades.

- Durability: They offer excellent impact resistance and last longer under wear, ideal for industrial applications.

- Maintenance-Friendly: Their surfaces are easy to clean and maintain, reducing downtime.

Applications of Aluminum Tread Plate Patterns

Aluminum tread plates with different proprietary patterns fulfill a vast range of industrial, commercial, and consumer needs:

| Industry | Typical Uses | Reasons for Use |

|---|---|---|

| Transportation | Truck floors, trailer beds, passenger vehicle stair-plates | Slip resistance, low weight to reduce vehicle load |

| Construction & Marine | Walkways, ramps, stair treads, dock platforms, ship decks | Corrosion resistance and skid prevention |

| Manufacturing & Warehousing | Machine protection coverings, toolboxes, forklift steps | Wear resistance, easy fabrication |

| Architecture & Interiors | Elevator flooring, allied wall panelings, aesthetic cladding and staircases | Sleek design with durability, light to install |

| Food & Chemicals | Work platforms, control panel flooring, sanitary safe tread mats | Corrosion resistance, easy cleaning |

| Consumer Goods | DIY decorative panels, door protection, cabinetry | Attractive looks with effective abrasion resistance |

| Parameter | Typical Range | Notes |

|---|---|---|

| Sheet Thickness | 1.5 mm to 10 mm | Standard thickness in mm |

| Width | 1000 mm to 2000 mm | Depends on production line |

| Length | Up to 6000 mm | Custom cut-to-length available |

| Finish | Polished, Mill finish, Anodized | Matte or glossy finishing |

| Pattern Height (Raise) | 0.5 mm to 6 mm | Higher raises generally better grips |

| Density | 2.7 g/cm³ | Aluminum Ich properties standard |

| Tensile Strength (dependent on alloy) | 90 - 300 MPa | Based on applied face and alloy |