Aluminum sheet mill finish heat sinks are engineered aluminum products specially designed to efficiently dissipate heat in a wide range of thermal management applications. They combine excellent thermal conductivity with lightweight and corrosion-resistant properties, making them ideal components in electronics, automotive, industrial, and HVAC industries.

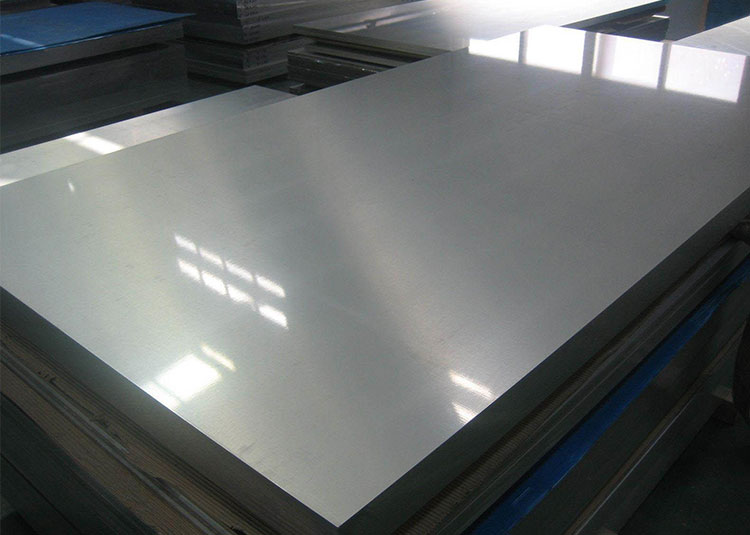

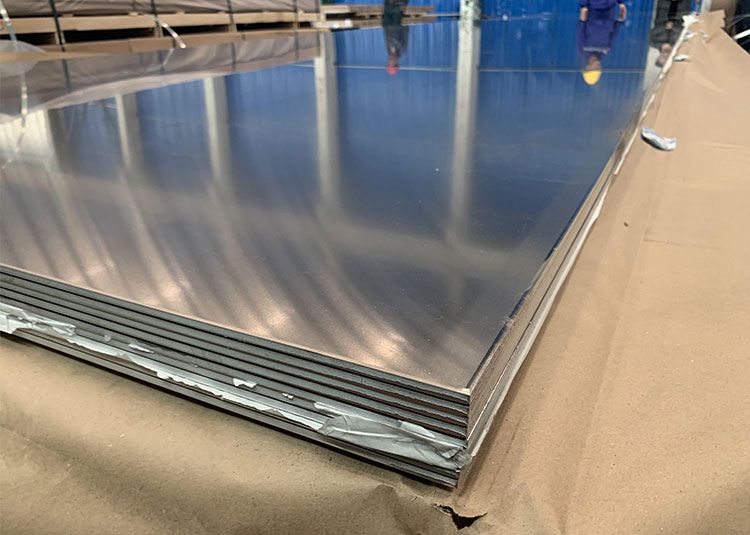

Mill finish aluminum sheets for heat sinks are typically produced by cold rolling or hot rolling aluminum alloys followed by a surface finish directly from the rolling mill, with no further surface treatment or polishing. This natural look is characterized by a slightly rough texture which provides adequate surface area to enhance heat dissipation.

The aluminum used is carefully selected for optimum thermal and mechanical properties, ensuring that the heat sinks have structural integrity while maximizing heat transfer efficiency. The sheets are easy to fabricate into various shapes, making them perfect for custom heat sink designs.

Features

| Feature | Description |

|---|---|

| Material | High thermal conductivity aluminum alloy |

| Surface finish | Mill finish (unzoned, raw texture) |

| Thermal conductivity | Excellent thermal performance (typical >200 W/m·K) |

| Lightweight | Density typically around 2.7 g/cm³ making them easier to handle |

| Corrosion resistance | Natural oxide layer formation for protection |

| Malleability and machinability | Easily shaped and machined using standard processes |

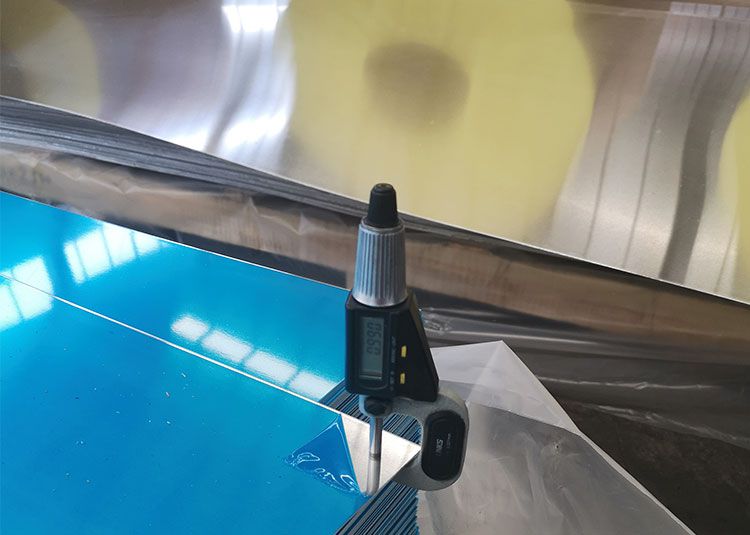

| Dimensional tolerance | Accurate thickness control for uniformity |

Chemical Composition

The most common alloys used for mill finish heat sink aluminum sheets are 1050 and 1060 series (commercially pure aluminium) due to their large thermal conductivity and excellent workability.

| Element | 1050 Aluminum (%) | 1060 Aluminum (%) |

|---|---|---|

| Aluminum (Al) | 99.5 min | 99.6 min |

| Silicon (Si) | 0.25 max | 0.25 max |

| Iron (Fe) | 0.40 max | 0.35 max |

| Copper (Cu) | 0.05 max | 0.05 max |

| Manganese (Mn) | 0.05 max | 0.03 max |

| Magnesium (Mg) | 0.05 max | 0.03 max |

| Zinc (Zn) | 0.05 max | 0.07 max |

| Titanium (Ti) | 0.03 max | 0.03 max |

| Other Elements | 0.15 max cumulatively | 0.15 max cumulatively |

Technical Specifications

| Parameter | Typical Values | Notes |

|---|---|---|

| Thickness | 0.2 mm – 6.0 mm | Can be customized per order |

| Width | Up to 1500 mm | Standard max; cutting available |

| Thermal Conductivity | 220 – 240 W/m·K | Depends on alloy purity |

| Density | ~2.71 g/cm³ | Lightweight |

| Tensile Strength | 50 – 110 MPa | Depends on temper and alloy |

| Elongation at break | 10 – 40 % | Allows easy forming & shaping |

| Coefficient of Thermal Expansion | ~23.1 x 10^-6 /℃ | Important for thermal cycling |

Applications

Aluminum sheet mill finish heat sinks are widely utilized in thermal management situations where metals balance cost-effectiveness and performance:

Electronics Cooling

Used in CPU coolers, LED lamp fixtures, power electronics devices for efficient heat rejection.Automotive parts

Applied in electric vehicle battery packs, power inverter cooling systems due to light weight and high thermal transfers.Industrial Equipment

Cooling panels in control cabinets, reactors, power converters.Telecommunications

Managing heat dissipation for telecom racks and base station electronics.HVAC Systems

Heat recovery ventilators, refrigeration equipment parts.

Advantages of Mill Finish

- No secondary surface finishing reduces cost and processing time

- Clean surface suitable for anodizing or painting if desired later

- Typical natural oxide layer helps corrosion resistance without extra coating

- Provides good grip and paint adhesion when finished

Aluminum sheet mill finish heat sinks offer a cost-effective, lightweight, and robust medium to support heat dissipation needs across diverse industries. The material's excellent thermal conductivity combined with mechanical properties delivers reliable thermal management performance, easing integration and customization to demanding design requirements.

When specifying heat sinks made with these mill finish aluminum sheets, it's critical to consider alloy purity, dimensional constraints, and final application environment, ensuring an optimized thermal solution that contributes to improved product longevity and efficiency.

For inquiries about custom sizes, thicknesses, and alloys or assistance in alloy selection specific to your heat sink needs, reach out to our engineering team for guidance.