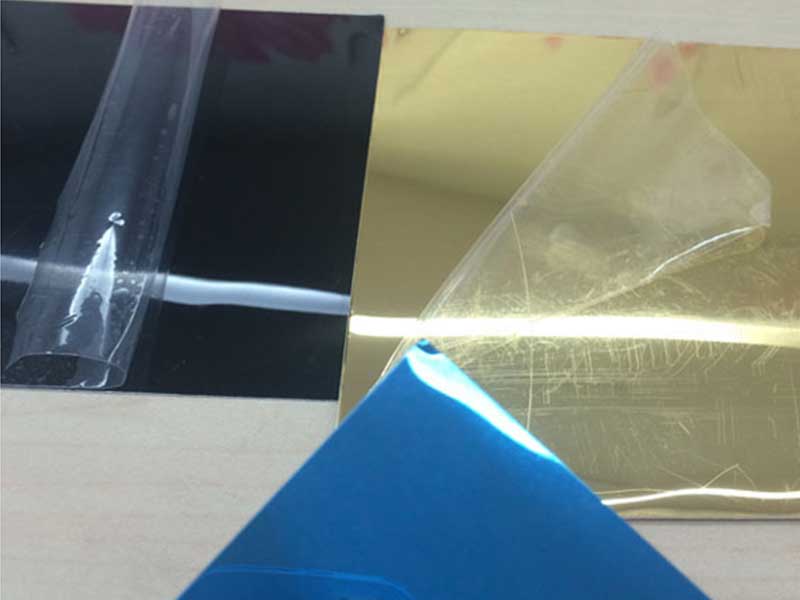

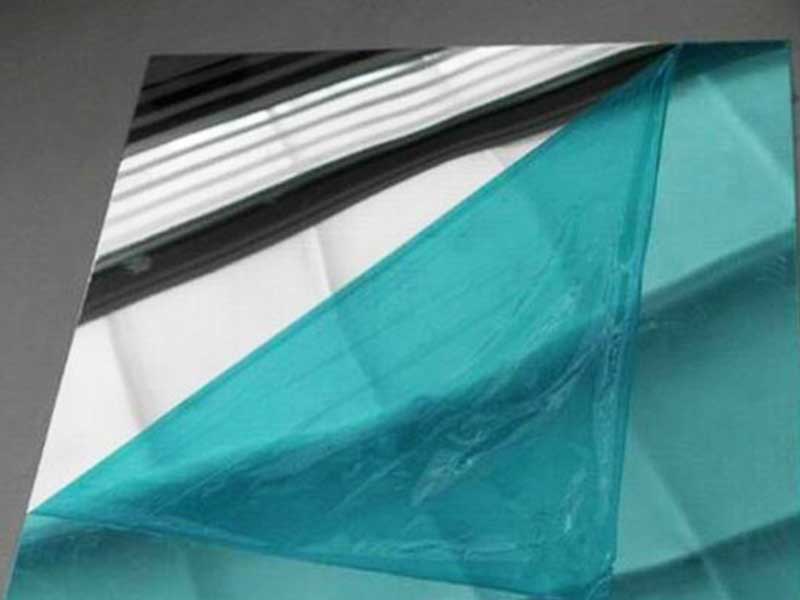

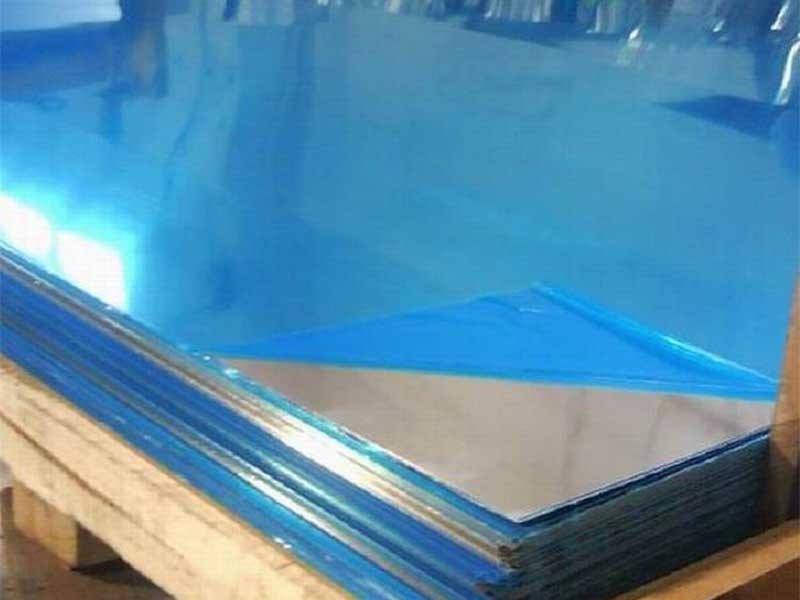

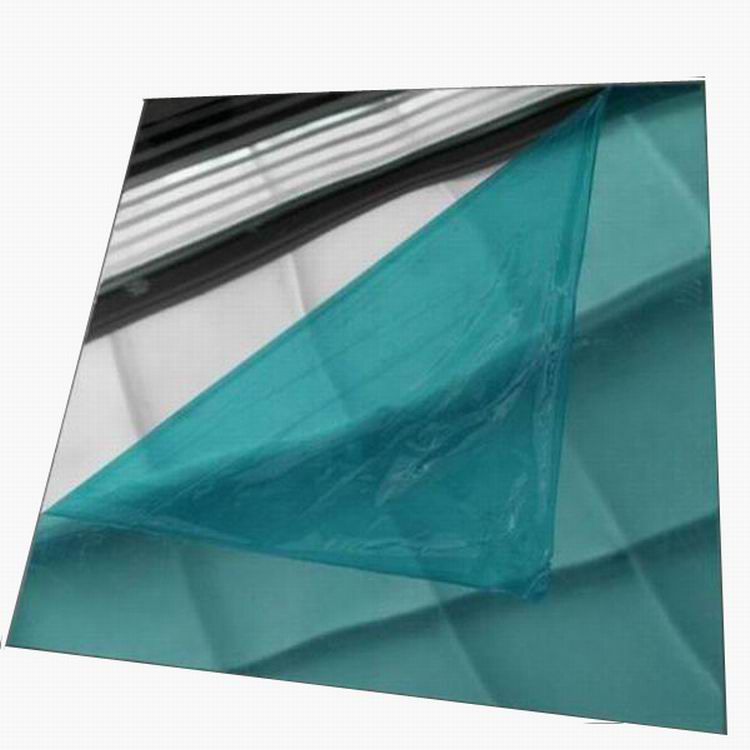

Both 1060 and 1100 aluminum alloys belong to the 1000 series aluminum family known for their high purity and excellent corrosion resistance. When processed into a mirror coil finish, the surface exhibits exceptional reflectivity and aesthetic quality, similar to a polished mirror. These attributes make mirror aluminum coils especially desirable in architectural designs, decorative and reflective surfaces, and sensitive electronic housings.

| Feature | 1060 Aluminum Coil | 1100 Aluminum Coil |

|---|---|---|

| Aluminum Purity | ≥ 99.6% Aluminum | ≥ 99.0% Aluminum |

| Common Finish | Mirror polished, with reflective surface | Mirror polished, with reflective surface |

| Chemical Series | 1000 series (commercially pure aluminum) | 1000 series (commercially pure aluminum) |

| Corrosion Resistance | Excellent | Excellent |

| Mechanical Strength | Medium | Slightly higher than 1060 |

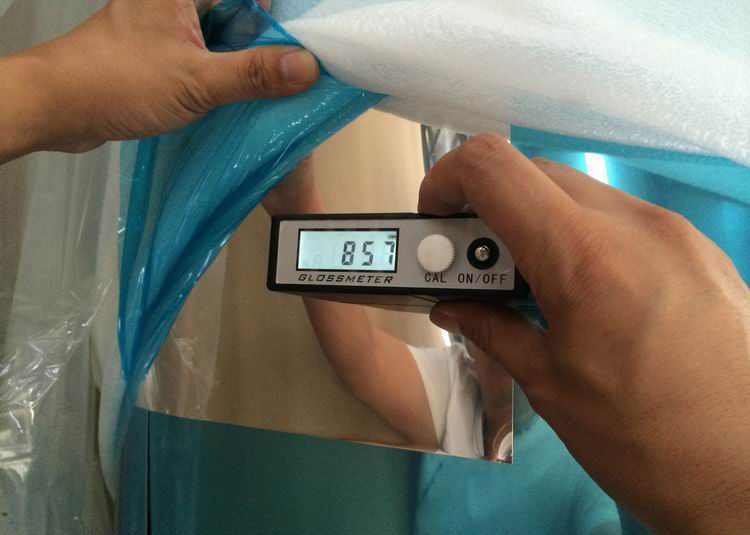

| Surface Quality | Extremely smooth & reflective surface | Extremely smooth & reflective surface |

2. Chemical Composition

The chemical composition for 1060 and 1100 aluminum mirror coils adheres to strictly controlled standards to maintain high purity and optimal working characteristics.

| Element | 1060 Alloy (wt%) | 1100 Alloy (wt%) |

|---|---|---|

| Aluminum (Al) | ≥ 99.60 | ≥ 99.00 |

| Copper (Cu) | 0.05 - 0.20 | 0.05 - 0.20 |

| Iron (Fe) | ≤ 0.35 | ≤ 0.95 |

| Manganese (Mn) | ≤ 0.03 | ≤ 0.05 |

| Silicon (Si) | ≤ 0.25 | ≤ 0.95 |

| Zinc (Zn) | ≤ 0.03 | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.03 | ≤ 0.03 |

| Others (each) | ≤ 0.03 | ≤ 0.05 |

| Others (total) | ≤ 0.10 | ≤ 0.15 |

3. Technical Specifications

| Parameter | 1060 Mirror Aluminum Coil | 1100 Mirror Aluminum Coil |

|---|---|---|

| Thickness Range | 0.1 mm – 3.0 mm | 0.1 mm – 3.0 mm |

| Width Range | 150 mm – 1600 mm | 150 mm – 1600 mm |

| Temper Available | H14, H16 | H14, H16 |

| Density | 2.71 g/cm³ | 2.71 g/cm³ |

| Surface Finish | Mirror polish (Mirror Grain) | Mirror polish (Mirror Grain) |

| Coiling Diameter | 450 mm – 1500 mm | 450 mm – 1500 mm |

| Maximum Coil Weight | Up to 8 tons | Up to 8 tons |

4. Mechanical Properties

Below mechanical property data presents how these mirror coils perform during manufacturing and final application:

| Property | 1060 Aluminum (H14) | 1100 Aluminum (H14) |

|---|---|---|

| Tensile Strength (MPa) | 79 – 97 | 90 – 110 |

| Yield Strength (MPa) | 39 – 63 | 40 – 70 |

| Elongation (%) | 8 – 15 | 3 – 15 |

| Hardness (Brinell) | 25 – 40 | 40 – 60 |

| Electrical Conductivity (% IACS) | ≥ 59 | ≥ 53 |

5. Benefits and Performance Highlights

- High reflectivity surface: Mirror aluminum coils present a crystal-clear, bright finish for aesthetic elegance and enhanced reflectivity.

- Excellent corrosion resistance: Suitable for outdoor and humid environments without significant degradation.

- Good workability: Easily bent and shaped using standard fabrication methods including cutting, welding, and bending with minimal risk of surface damage.

- Electrical and thermal conductivity: Performs well as housings or components for technologies requiring effective heat and electrical conduction.

- Non-toxic and environment-friendly: Fully recyclable aluminum with no toxic coatings increases sustainability compliance.

6. Typical Use Cases

| Industry | Application | Benefits |

|---|---|---|

| Architecture | Decorative panels, ceiling tiles, elevator claddings | Long-lasting, elegant surface resistant to weathering |

| Household Goods | Kitchen utensils, cookware, container walls | Safe, corrosion-resistant, pleasing design |

| Electronics | Reflective internal parts, heatsinks | Optimal reflective and heat conduction |

| Automotive | Mirror bright trims, panels, decorative strips | Lightweight, corrosion-resistant aesthetic |

| Other Industries | Advertising signs, laser mirrors, machinery covers | Customizable, strong reflective coatings |

1060 and 1100 mirror aluminum coils combine the high purity and corrosion resistance of the 1000 aluminum series with a distinctive mirror-like polished finish. Offering excellent strength and superb surface aesthetic, these coils serve a wide variety of industrial and decorative applications where performance and appearance are critical.

If you seek a durable, versatile, and visually attractive aluminum product, 1060 & 1100 mirror aluminum coils should be a primary consideration for your manufacturing or architectural needs.

For purchasing, customization or technical consultation please contact our specialist team to receive expert advice tailored to your specific project requirements.