PVDF (Polyvinylidene Fluoride) coated standard aluminum sheets represent a pinnacle of performance for a variety of applications in architectural and industrial contexts. Renowned for their resistance to weather and chemical exposure and outstanding durability, these coated sheets have become essential in modern construction and manufacturing processes.

Features

- Exceptional Weather Resistance: PVDF coatings are designed for superior protection against UV exposure, humidity, and varying temperatures.

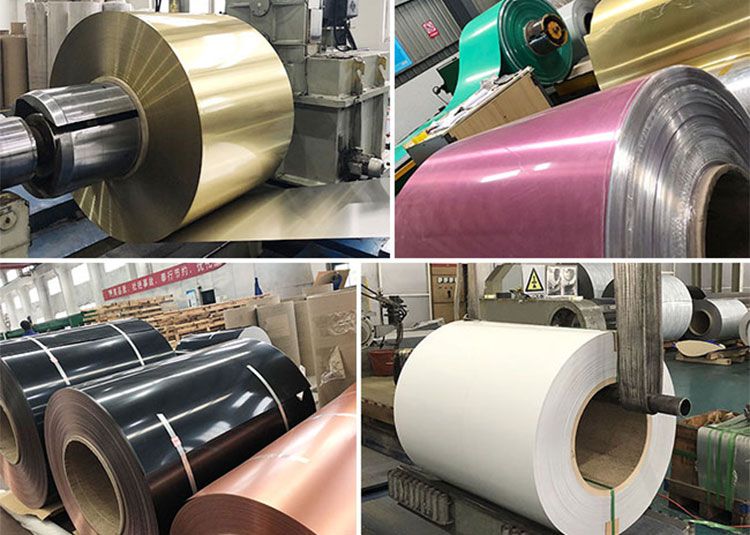

- Long-lasting Aesthetic Appeal: These coatings maintain their bright color and finish without fading, making them ideal for exterior applications.

- Chemical Resistance: PVDF possesses excellent resistance to a broad range of chemicals, ensuring that it remains intact in demanding environments.

- Easy Maintenance: PVDF-coated aluminum sheets require minimal maintenance while maintaining their aesthetic appearance over time.

- Superb Durability: Known for high tensile strength, they are excellent for sustaining weight and unaffected by environmental pollutants.

Applications

PVDF coated standard aluminum sheets are widely used across several sectors:

- Architectural Applications: Facades, roofing materials, window frames.

- Industrial Uses: Chemical processing equipment, storage institutions, and machinery housings.

- Transportation: Panel systems in buses, trains, and airplanes.

- Signage: Outdoor and indoor signage requiring durability and longevity.

- Consumer Products: Cases, electronic device housings, and more.

Technical Specifications

Below is a comprehensive breakdown of the technical specifications and properties of PVDF coated aluminum sheets.

Physical and Mechanical Properties

| Properties | Value |

|---|---|

| Alloy | 3003, 3105, 5005 |

| Temper | H14, H24 |

| Coating Thickness (PVDF) | 20 - 25 microns |

| Aluminum Sheet Thickness | 0.5 mm - 3 mm |

| Tensile Strength | ≥ 299 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 12% |

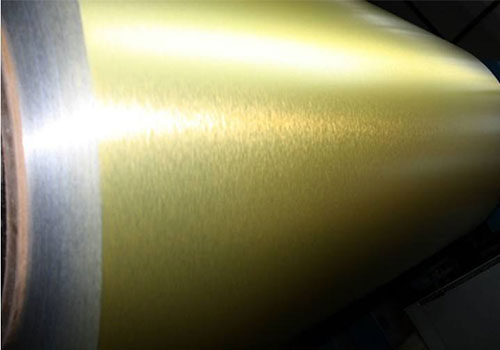

| Surface Finish | Metallic, Matte, Textured |

Chemical Composition

| Element | Content (%) |

|---|---|

| Aluminum (Al) | Remainder (Balance) |

| Manganese (Mn) | 1.0 - 1.5 |

| Magnesium (Mg) | 0.7 - 1.0 |

| Zinc (Zn) | 0.1 (Max) |

| Silicon (Si) | 0.5 (Max) |

| Copper (Cu) | 0.1 (Max) |

Coating Information

| Parameter | PVDF Coating |

|---|---|

| Coating System | Two-coat process |

| Color Retention | ≥ 80% (for 10 years) |

| Heat Resistance | Up to 150°C |

| Impact Resistance | Excellent |