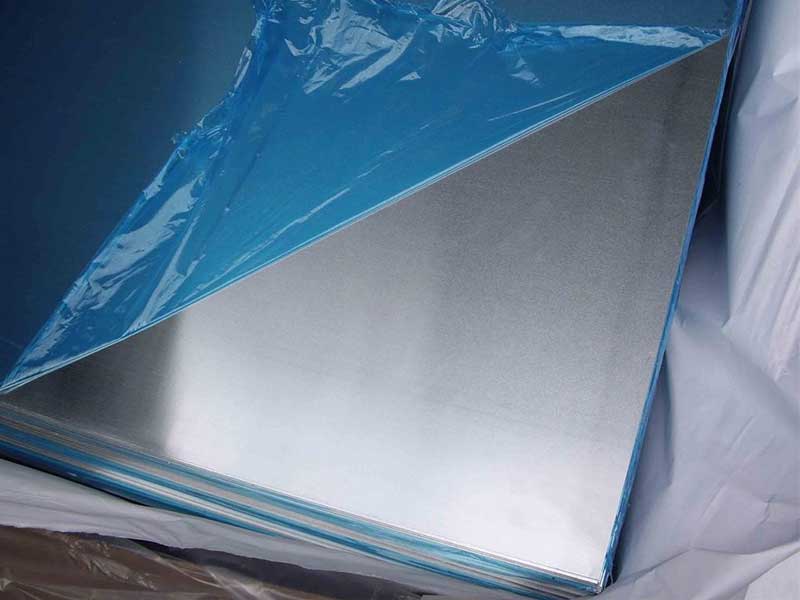

When it comes to selecting materials for structural, industrial, or creative projects, the characteristics of aluminium sheets can unlock new possibilities. In particular, the aluminium sheet 5mm thickness occupies a noteworthy middle ground—offering an ideal balance between strength, rigidity, flexibility, and ease of fabrication.

Why Focus on 5mm Thickness for Aluminium Sheets?

Five millimeters might seem like an arbitrary value, but it remarkably embodies a tipping point where aluminium’s uniquely favorable properties become exceptionally useful:

- Structural integrity: At 5mm, the aluminium sheet provides considerable rigidity for applications like chassis panels without excessive weight.

- Manufacturability: It maintains enough pliability for cutting, forming, and welding yet is thick enough to resist buckling under load.

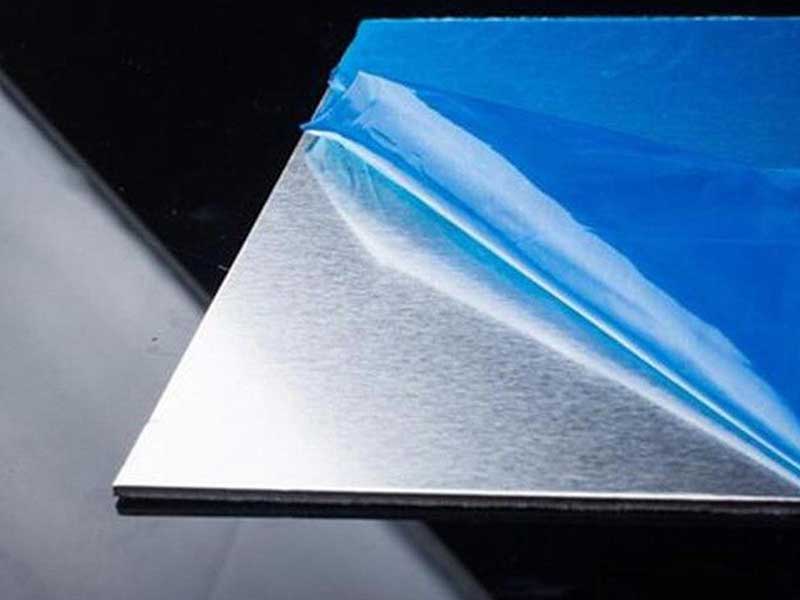

- Surface finish: This thickness superbly incorporates surface treatments such as anodizing without compromising mechanical reinforcement.

From custom fabrications to standardized industrial parts, the aluminium sheet 5mm combines physical resilience with versatility of use unmatched by thinner or excessively thick alternatives.

Technical Details & Mechanical Parameters

Aluminium sheets come in various alloys and treatments affecting their comportment under use. For a 5mm sheet, typical engineering details manifest as follows:

| Parameter | Typical Value | Notes |

|---|---|---|

| Thickness | 5 mm (±0.1 mm) | Precision thickness tolerances matter |

| Density | ~2.70 g/cm³ | Consistent across most alloys |

| Tensile Strength | 200 - 450 MPa | Dependent on alloy and temper |

| Yield Strength | 110 - 410 MPa | Critical for structural design |

| Elongation at Break | 8 - 20 % | Varies with tempering |

| Thermal Conductivity | ~220 W/m·K | Helpful in heat dissipation designs |

| Electrical Conductivity | Approximately 35-60% IACS | Important for electromagnetic uses |

Alloy Grades and Temper Conditions for 5mm Aluminium Sheets

Aluminium's versatility comes from its range of alloys and tempers (heat treatments or mechanical work that tune its mechanical properties).

Common Alloys:

1xxx series (pure Al, 99%+): Outstanding corrosion resistance, excellent electrical and thermal conductivity but lower strength. Suitable for chemical tanks and electrical components.

3xxx series (Al-Mn): Moderate strength and outstanding corrosion resistance, widely used in roofing, siding, and vehicle bodies.

5xxx series (Al-Mg): High strength and excellent corrosion resistance, favored for marine environments, pressure vessels, welding applications.

6xxx series (Al-Mg-Si): Combines good strength, machinability, corrosion resistance; ideal for structural components, automotive panels.

Temper Designations (Examples):

- O (Annealed): Fully soft and ductile, great for forming.

- H14/H18 (Strain Hardening): Moderate to maximum hardness obtained through cold working; increases strength but reduces ductility.

- T4/T6 (Heat Treated): Controlled mechanical properties balancing strength and elasticity. T6 temper involves solution heat treatment and artificial aging, optimizing strength.

For a 5mm sheet, the choice precisely depends on your eventual application. For example, a 5xxx series, H32 compositon—partially strain-hardened and stabilized—is especially popular for industrial pressure components and welded constructions, thanks to its durability and weldability.

Implementation Standards and Industry Compliance

The aluminium industry follows strict global benchmarks ensuring dimensional accuracy, so the end user need not worry about specification ambiguities. Especially for the 5mm sheets, typical standards guide dimensions, mechanical requirements, chemical composition, and surface finishes, including but not limited to:

- ASTM B209: Standard Specification for Aluminium and Aluminium-Alloy Sheet and Plate.

- EN 485-2: Aluminium and aluminium alloys — Sheet, strip and plate — Part 2: Mechanical properties.

- ISO 6361: Technical specifications for aluminium and aluminium alloys sheets, strips, and plates.

- JIS H4100: Japanese standard for Aluminium and Aluminium alloy sheets.

These protocols confirm proper thickness tolerance, edge conditions, temper markings, and chemical properties matching each alloy designation.

Focusing on a popular alloy for 5mm sheets — 5052-H32 (Al-Mg based) — here's its chemical composition typical range:

| Element | Content Range (%) | Function |

|---|---|---|

| Aluminium | Balance (~97.25 – 98.25) | Base metal giving light weight, conductivity |

| Magnesium | 2.2 – 2.8 | Increases strength and corrosion resistance |

| Chromium | 0.15 – 0.35 | Grain refiner preventing corrosion in welded areas |

| Iron | ≤ 0.4 | Impurity, affects toughness |

| Silicon | ≤ 0.25 | Improves casting characteristics |

| Copper | ≤ 0.1 | Controlled because it affects corrosion resistance |

| Manganese | ≤ 0.1 | Limits formation of brittle phases |

Real-world Uses and Why 5mm Aluminium Sheet Shines

Where does this technical beauty really find its starring role? Observe these zones typically benefiting from 5mm sheet:

- Automotive body panels and reinforcements: Rigidity needed for crash or impact resistance, without ridiculing overall vehicle weight goals.

- Shipbuilding and marine equipment: Saltwater resilience to last decades; file and weld responses enhancing recoverability post assembly.

- Architectural cladding: Both aesthetic variation and weatherproof, long-lasting facades material.

- Custom fabrication & prototyping: Tool-friendly for machining and adjusting thickness before final application.