Marine aluminum tubes have become indispensable in the marine and offshore industries, serving a critical role in precision engineering applications. Their remarkable combination of lightweight strength, corrosion resistance, and machinability makes them ideal for fabricating tailor-made components under stringent engineering requirements.

Custom Marine Aluminum Tubes in Precision Engineering

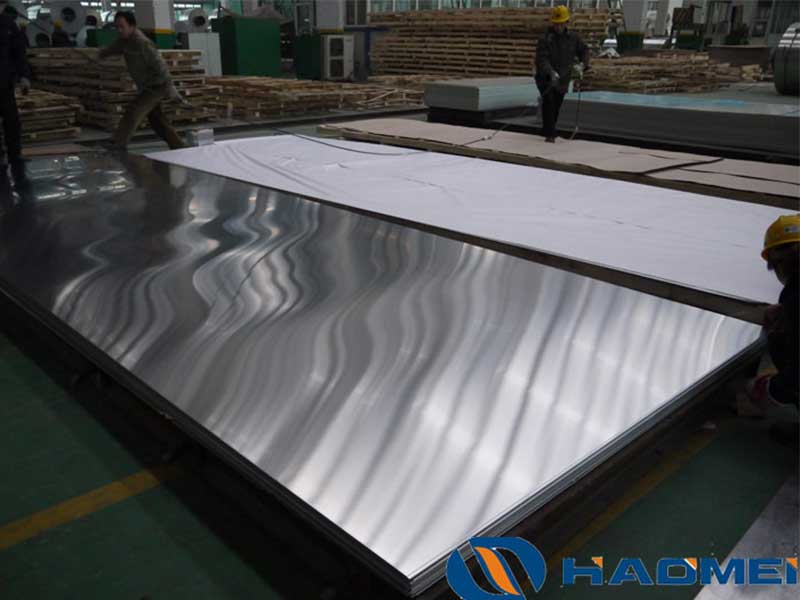

At its core, marine aluminum tubing involves the use of high-grade aluminum alloys specially designed for harsh marine environments. Precision engineering demands metal tubes that not only conform to exact ground and internal/external dimensions but also maintain structural integrity under rigorous mechanical stress and corrosive sea water exposure.

A custom marine aluminum tube effectively substantiates this, allowing engineers to meet project specifications through tailored dimensions, alloy compositions, and finishings. Its primary functions derive from:

- Corrosion resistance: Critical in salt water environments to prevent metal degradation.

- High strength-to-weight ratio: Ensures components are lightweight yet sturdy.

- Thermal conductivity: Assists in heat dissipation in engineering applications.

- Machinability: Facilitates precision crafting for complex shapes and threads.

- Weldability: Ensures seamless integration and assembly in engineering constructs.

Applications of Marine Aluminum Tubes in Precision Engineering

In marine engineering and beyond, custom aluminum tubes are employed widely in:

- Shipbuilding: Frame gating, piping, and support structures that maintain mechanical strength without adding excessive weight.

- Offshore platforms: Structural piping systems and mounting tubes that withstand sea water corrosion.

- Hydraulic and pneumatic systems: Tubes machined for high-pressure fluid conveyance.

- Marine navigation equipment: Tubes configured for housing instruments requiring exact dimensional accuracy.

- Renewable energy: Structural frames for offshore wind turbines demanding maximal strength at lightweight parameters.

- Aerospace-analogous structures: Given their corrosion resistance and strength, used in marine equipment integrally designed for precision measurement tools integrated into aerial drones monitoring maritime conditions.

Technical Parameters of Custom Marine Aluminum Tubes

Parameters that precisely define the qualities of custom aluminum tubes for marine use include:

| Parameter | Value / Specification | Description |

|---|---|---|

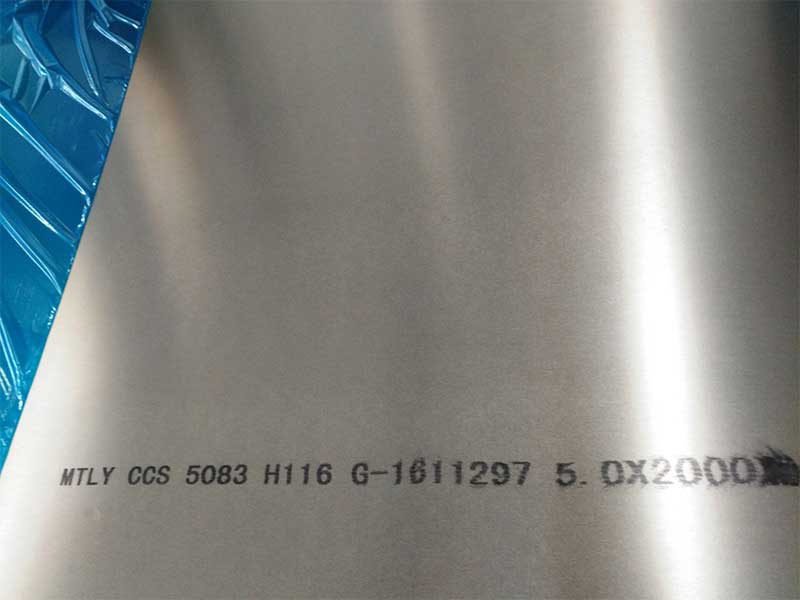

| Material Alloy | ASTM B221 6061-T6 / 5083-H112 | High strength, corrosion-resistant aluminum |

| Temper | T6, H112, O (annealed), ... | Defines mechanical properties and hardness |

| Tube Outer Diameter | 6 mm to 150 mm+ | Customizable for specific project needs |

| Wall Thickness | 0.5 mm to 15 mm | Thickness ensures structural performance |

| Length | Cut-to-length as requested | Tailored to application requirements |

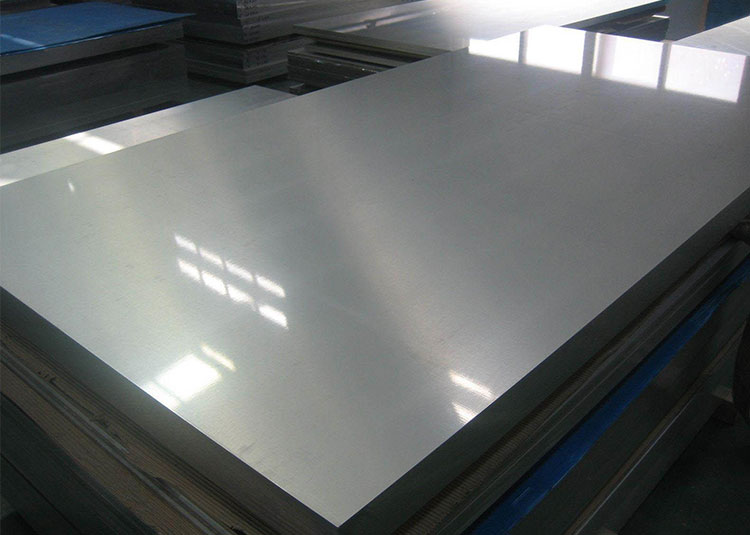

| Surface Finish | Mill finish, anodized, brushed | Enhances corrosion resistance and aesthetics |

| Tensile Strength | 290-350 MPa (6061-T6) | Reflects load-bearing capacity |

| Yield Strength | 240 MPa (6061-T6) | Stress limit before permanent deformation |

| Elongation | 8-12% | Ductility demonstrating flexibility |

| Density | 2.7 g/cm³ | Light inherent material advantage |

Alloy Composition and Chemical Properties

Custom marine aluminum tubes often use specialized alloys, notably 6061 and 5083, prized for their marine grade resistance and machining potential. The typical chemical composition of these alloys is:

| Element | 6061 Alloy (%) | 5083 Alloy (%) |

|---|---|---|

| Aluminum (Al) | 97.9 – 98.6 | 93.0 – 94.4 |

| Silicon (Si) | 0.4 – 0.8 | 0.4 (max) |

| Iron (Fe) | 0.7 (max) | 0.4 (max) |

| Copper (Cu) | 0.15 – 0.4 | 0.1 (max) |

| Manganese (Mn) | 0.15 – 0.4 | 0.4 – 1.0 |

| Magnesium (Mg) | 0.8 – 1.2 | 4.0 – 4.9 |

| Chromium (Cr) | 0.04 – 0.35 | 0.05 – 0.25 |

| Zinc (Zn) | 0.25 (max) | 0.25 (max) |

| Titanium (Ti) | 0.15 (max) | 0.15 (max) |

- 6061-T6: Heat-treated alloy balanced for good strength, corrosion resistance, and machinability.

- 5083-H112: Non-heat-treatable but weldable, superior to 6061 in seawater corrosion resistance, ideal for structural marine frames.

Tempering and Mechanical Conditions

The temper of aluminum tubing—defined heat-treatment-state—alters mechanical properties, defined as follows:

- T6 Temper: Solution heat treated, artificial aging; best strength for structural parts.

- H112 Temper: Strain-hardened with limited forming hardness (common in 5083 alloy).

- O Temper: Annealed, soft and ductile state, perfect for complex machining but lower strength.

The appropriate temper selection hinges on balancing strength, crack resistance, and developability of shapes critical in manufacturing endurance quality marine components.

Implementation Standards That Ensure Quality

Quality assurance in marine aluminum tubes depends on adherence to strict standards:

- ASTM B221: Specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes.

- ISO 6362: Standards for wrought aluminum and magnesium alloys.

- ABS, DNV-GL, Lloyd’s Register: Classification society standards guaranteeing resistance to corrosion and structural integrity in marine applications.

- RoHS and REACH compliance: Environmental regulations for materials in sensitive aqueous or ecological environments.

Compliance certifies that the tubes can survive operational conditions offshore and free from harmful substances, thereby facilitating peacetime and critical incident resistance integrity.

Concluding Remarks: Why Choose Custom Marine Aluminum Tubes for Precision Engineering?

Selecting custom marine aluminum tubes tuned exactly to engineering specifications effectively impacts vessel weight, longevity of marine infrastructure, and ease of maintenance. By leveraging advanced alloys like 6061-T6 or 5083-H112, optimized tempering, precision machining, and adhering to industry standards, these tubes offer unmatched performance. For precision critical engineering—from maritime hydraulics to complex offshore renewable frameworks—custom tubes epitomize the synergy of metal science and marine engineering needs.

Contact us today to discover how our custom marine aluminum tubing solutions bring precision and durability to your marine engineering projects.