Aluminum sheet is one of the core materials in modern boat and marine structure manufacturing. Among them, 1100, 3003, 5052, 5083, and 6061 aluminum sheet cover a complete performance range from economical non-heat-treatable sheet for general marine fittings to high‑strength, corrosion‑resistant plate for hulls, decks, and structural components.

| Alloy | Series | Main Feature | Typical Marine Use |

|---|

| 1100 | 1xxx | High purity, excellent corrosion & formability | Nameplates, interior panels, light covers |

| 3003 | 3xxx | Manganese alloy, better strength than 1100 | Cabinets, tank covers, non-structural panels |

| 5052 | 5xxx | Good strength, good corrosion & weldability | Small boat hulls, deck plates, consoles |

| 5083 | 5xxx | Very high strength in 5xxx, marine-grade | Hulls, decks, cross-structures, bulkheads |

| 6061 | 6xxx | Heat-treatable, high strength & machinability | Brackets, frames, masts, joinery, hardware |

2. Chemical Composition

(Typical values, wt%)

2.1 1100 Aluminum Sheet

| Element | Si + Fe | Cu | Mn | Zn | Others (each) | Al |

|---|

| 1100 | ≤0.95 | 0.05–0.20 | ≤0.05 | ≤0.10 | ≤0.05 | ≥99.00 |

2.2 3003 Aluminum Sheet

| Element | Si | Fe | Cu | Mn | Zn | Others (each) | Al |

|---|

| 3003 | ≤0.6 | ≤0.7 | 0.05–0.20 | 1.0–1.5 | ≤0.10 | ≤0.05 | Balance |

2.3 5052 Aluminum Sheet

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Al |

|---|

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | Balance |

2.4 5083 Aluminum Sheet (Marine Grade)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40–1.0 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | Balance |

2.5 6061 Aluminum Sheet

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|

| 6061 | 0.40–0.80 | ≤0.70 | 0.15–0.40 | ≤0.15 | 0.80–1.20 | 0.04–0.35 | ≤0.25 | ≤0.15 | Balance |

point:

- 5xxx series (5052/5083): Mg as main alloying element ⇒ excellent seawater corrosion resistance.

- 6061: Mg + Si system ⇒ can be heat treated for higher strength and good machining.

3. Mechanical Properties & Technical Specifications

3.1 Typical Mechanical Properties

(Representative values at room temperature; exact values depend on temper and thickness)

| Alloy | Common Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Remarks |

|---|

| 1100 | H14 | 110–145 | 95–125 | 5–10 | Soft, easy forming |

| 3003 | H14 | 130–180 | 115–160 | 5–12 | Higher strength vs 1100 |

| 5052 | H32 | 215–265 | 160–215 | 7–12 | Good marine hull material |

| 5083 | H116 / H321 | 275–350 | 125–215 | 10–17 | Marine-grade, high strength |

| 6061 | T6 | 240–310 | 200–260 | 6–12 | Heat-treated, stiff parts |

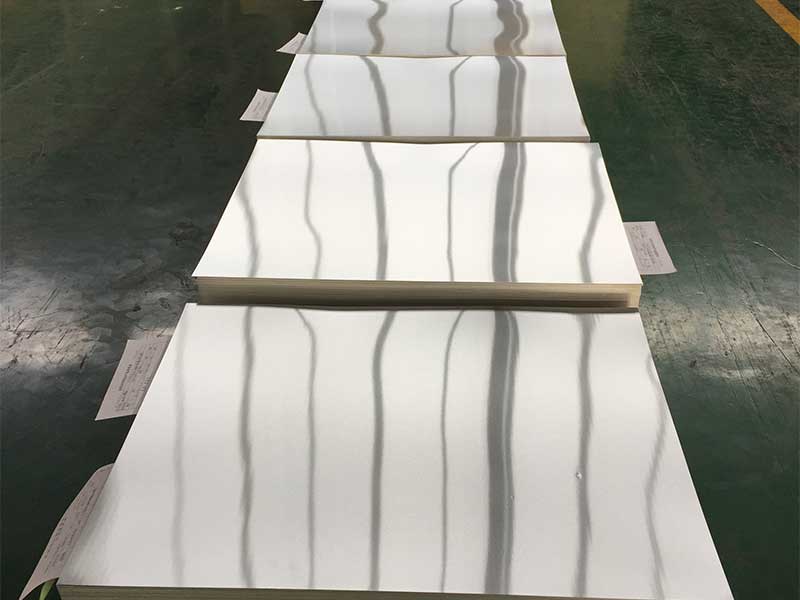

3.2 Typical Supply Range

| Parameter | 1100 & 3003 | 5052 & 5083 (Marine) | 6061 |

|---|

| Thickness (mm) | 0.2–6.0 | 1.0–100 | 1.0–100 |

| Width (mm) | 500–2000 | 1000–2600 | 1000–2600 |

| Length (mm) | 1000–12000 | 1000–12000 | 1000–12000 |

| Surface | Mill, brushed | Mill, anti-slip, coated | Mill, anodized-capable |

| Standards (typical) | ASTM B209 | ASTM B928 / B209 | ASTM B209 |

(Custom dimensions and tempers can be produced according to drawings and standards such as ABS, DNV, LR, CCS for marine classification.)

4. Performance in Marine Environments

4.1 Corrosion Resistance in Seawater

| Alloy | Seawater Corrosion Resistance | Typical Use on Boat |

|---|

| 1100 | Good in atmosphere, fair in seawater | Interior, dry areas, decorative parts |

| 3003 | Better than 1100, not for immersion | Casings, covers, furniture in cabin |

| 5052 | Very good, suitable for splash zones | Small hulls, side plates, deck plates |

| 5083 | Excellent, long-term seawater contact | Hull bottom, bilge areas, structural members |

| 6061 | Good, but cautious in immersion + crevice | Frames, brackets, masts, not for unprotected bottoms |

Highlights:

- 5083 is the preferred alloy for full marine immersion and structural hull parts.

- 5052 is ideal for light hulls, deck houses, and non‑critical structural plates.

- 1100 & 3003 are mainly used in non-immersion, non-load-bearing areas.

- 6061 is excellent where high stiffness and precise machining are needed, away from stagnant seawater pockets.

5. Advantages of Using These Alloys for Boat Construction

5.1 Lightweight & Fuel Efficiency

| Parameter | Typical Value (Al Alloys) | Note |

|---|

| Density | ~2.70 g/cm³ | ~1/3 of carbon steel |

| Weight reduction vs steel | 40–60% | Depending on design & structure |

| Fuel savings (indicative) | 8–15% vs steel hull | Over long-term operation |

A lighter hull enables:

- Lower fuel consumption

- Higher payload capacity

- Better acceleration and maneuverability

5.2 Excellent Formability & Weldability

- 1100 & 3003:

- Outstanding bendability, suitable for deep drawing, stamping, and curved interior panels.

- 5052 & 5083:

- Very good MIG/TIG weldability, low tendency to hot cracking, widely used in continuous hull welding.

- 6061:

- Weldable, but strength decreases in the heat-affected zone; often used in machined and bolted structures.

6. Typical Boat and Marine Applications

6.1 Hulls & Structural Components

| Component | Recommended Alloys | Reasons |

|---|

| Hull bottom & side shell | 5083 (H116/H321), 5052 | High corrosion resistance & strength |

| Deck panels | 5052, 5083 | Good stiffness, corrosion resistance |

| Bulkheads & frames | 5083, 6061 (for non-immersed) | Structural strength, rigidity |

| Keel sections (aluminum boats) | 5083 | High load and impact resistance |

6.2 Superstructures & Outfitting

| Part | Recommended Alloys | Notes |

|---|

| Cabins, wheelhouses, roofs | 5052, 3003 | Light, easy forming |

| Railings, ladders, handrails | 6061, 5052 | Strength + corrosion resistance |

| Consoles, cabinets, lockers | 1100, 3003, 5052 | Non-structural, cosmetic, light |

| Floors & anti-slip plates | 5052, 5083 | Can be patterned (checker plate) |

6.3 Auxiliary & Special Marine Use

| Application | Alloy | Feature |

|---|

| Fuel & fresh water tanks | 5052, 5083 | Good corrosion, weldability |

| Marine tool boxes | 3003, 5052 | Formable, durable |

| Brackets for motors & equipment | 6061 | High strength, good machining |

| Decorative trim & nameplates | 1100, 3003 | Easy stamping, good surface appearance |

7. Comparison of Alloys for Boat Designers

7.1 Selection Guide

| Criterion | 1100 | 3003 | 5052 | 5083 | 6061 |

|---|

| Strength | ★ | ★★ | ★★★ | ★★★★ | ★★★★ |

| Seawater resistance | ★★ | ★★ | ★★★ | ★★★★★ | ★★★ |

| Weldability | ★★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★ |

| Formability | ★★★★★ | ★★★★ | ★★★★ | ★★★ | ★★★ |

| Machinability | ★★ | ★★ | ★★★ | ★★★ | ★★★★★ |

| Cost | ★★★★★ | ★★★★ | ★★★ | ★★ | ★★★ |

(★ = low, ★★★★★ = excellent)

7.2 Typical Use Strategy in One Boat

A practical way many shipyards work:

- 5083: Main hull plating, bottom, and bilge where strength & seawater immersion are critical.

- 5052: Decks, superstructures, interior panels that still require good corrosion resistance and moderate strength.

- 6061: Structural brackets, engine supports, precision frames, and machined fittings above waterline.

- 3003 & 1100: Interior, liners, cabinets, trims, and labels where cost and formability matter more than strength.

8. Processing & Surface Treatment

8.1 Processing Methods

| Process | Suitability | Notes |

|---|

| Cutting | All alloys | Shearing, plasma, waterjet, CNC routing |

| Bending | Best with 1100, 3003, 5052 | Observe minimum bend radius to avoid cracking |

| Welding | Best with 5052 & 5083, good with 6061 | Use ER5xxx filler for 5xxx alloys |

| Machining | Best with 6061 | Recommended where tight tolerances required |

8.2 Surface Options for Marine Use

| Treatment | Function |

|---|

| Mill finish | Standard surface for structural use |

| Brushed / polished | For decorative and visible surfaces |

| Anodizing (esp. 6061, 5052) | Enhanced corrosion & appearance |

| Marine paint / coating | Extra protection in harsh seawater |

| Anti-slip pattern (checker plate) | Deck safety |

9. Benefits for Shipyards and Owners

- Long service life in marine environments, especially with 5052 and 5083.

- Reduced maintenance costs versus steel due to better corrosion resistance and no rust scaling.

- Lower weight, allowing higher payload or better speed at the same power.

- Flexible design, from small fishing boats and workboats to yachts and patrol craft.

- Good recyclability, making aluminum boats more environmentally friendly.

1100, 3003, 5052, 5083, and 6061 aluminum sheets together provide a complete solution set for boat construction:

- 1100/3003: economical, easily formed for non-structural, interior and decorative parts.

- 5052: versatile hull and deck material, balancing cost, strength, and corrosion resistance.

- 5083: core marine‑grade plate for high‑stress, long‑term seawater immersion regions.

- 6061: high‑strength, machinable alloy for frames, supports, and precision marine fittings.

By matching each alloy to the correct location and loading condition on the boat, designers and builders can obtain reliable performance, reduced weight, and long-term durability in demanding marine environments.