Double Aluminum Foil with PET Core (AL PET AL) is a laminated shielding material engineered specifically for submarine communication cables. It combines two layers of high-purity aluminum foil with a tough polyethylene terephthalate (PET) film core, delivering excellent electromagnetic shielding, moisture barrier performance, and long‑term mechanical stability under deep‑sea pressure and corrosive environments. Ideal for fiber‑optic and power‑feeding submarine cables, AL PET AL improves signal integrity, extends service life, and optimizes total cable reliability.

Double Aluminum Foil with PET Core (AL PET AL) is a trilaminate structure designed for high‑reliability subsea environments:

- Outer aluminum foil for continuous shielding and corrosion resistance

- PET core film for mechanical strength, tear resistance, and dimensional stability

- Inner aluminum foil for redundant shielding and moisture barrier performance

In submarine communication cables, this laminate wraps around optical fiber bundles or conductor groups to protect against electromagnetic interference (EMI), radio‑frequency interference (RFI), moisture ingress, and mechanical stresses produced during laying, retrieval, and decades of seabed service.

Features and Benefits

Shielding Performance

- Dual aluminum layers form a quasi‑360° Faraday cage around sensitive elements

- Very low transfer impedance and high shielding effectiveness across a wide frequency band

- Stable shielding even under repeated bending and hydrostatic pressure

Moisture and Corrosion Resistance

- Aluminum layers act as a highly effective vapor barrier

- PET core resists hydrolysis and maintains tensile properties in humid and saline conditions

- Optional corrosion‑protected or coated aluminum surfaces enhance resistance in aggressive seawater environments

Mechanical Strength and Flexibility

- PET core delivers tensile strength and puncture resistance

- Composite maintains flexibility for tight cable bending radii and dynamic laying operations

- Good delamination resistance between AL and PET layers under thermal cycling

Thermal and Chemical Stability

- Stable in the typical operating temperature range of submarine cables

- Resistant to common cable filling compounds, gels, and lubricants

- Low shrinkage PET ensures stable geometry during manufacturing and in service

Processability

- Compatible with longitudinal or helical taping heads in cable production lines

- Suitable for bonding with cable jackets and water‑blocking elements

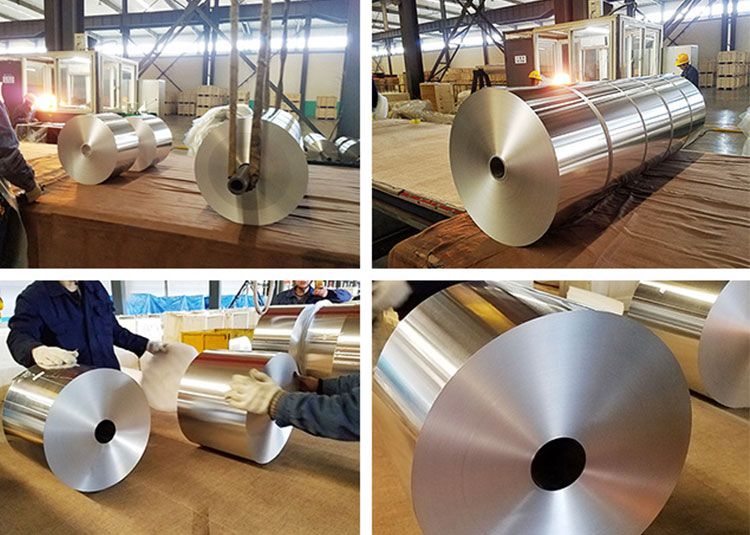

- Available in various slit widths and coil configurations to match line requirements

Typical Applications in Submarine Communication Cables

Optical Fiber Submarine Cables

- Shielding of fiber‑optic cores against external EMI from power cables, repeaters, and nearby high‑voltage systems

- Protection of optical fibers from microbending due to external pressure and mechanical contact with armor wires or strength members

- Barrier layer between fiber tube assemblies and metal armoring

Power‑Feeding and Hybrid Cables

- Shielding around power‑feeding conductors used to energize repeaters and amplifiers

- Isolation between DC power cores and optical elements in hybrid power‑fiber submarine cables

- Additional safety layer to minimize risk of stray currents and induced noise

Repeater and Junction Box Assemblies

- Localized shielding in repeater housings and branching units

- Laminate wraps for internal jumper cables and flexible leads inside pressurized housings

Structure and Layer Configuration

| Layer Position | Material | Typical Thickness Range | Primary Function |

|---|

| Outer Layer | Aluminum foil (AL) | 9–25 μm | EMI/RFI shielding, vapor barrier, corrosion |

| Core Layer | PET film (polyester) | 12–36 μm | Mechanical strength, puncture & tear resistance, dimensional stability |

| Inner Layer | Aluminum foil (AL) | 9–25 μm | Redundant shielding, vapor barrier, internal reflection |

Note: Thickness values can be customized according to cable design, mechanical load, and shielding requirements.

Representative Technical Specifications

Base Aluminum Foil Properties

| Property | Typical Value | Test Standard / Notes |

|---|

| Alloy designation | 1235 / 1145 / 8011 | High‑purity or cable‑grade alloys |

| Temper | O, H18 (as specified) | Soft (O) or hard (H18) |

| Aluminum purity (1235) | ≥ 99.35 wt% | EN / AA designation |

| Tensile strength | 60–120 MPa | Depends on temper and thickness |

| Elongation at break | ≥ 2–10 % | Higher in soft temper |

| Surface type | Bright / matte / treated | For adhesion or bonding if needed |

PET Core Film Properties

| Property | Typical Value | Notes |

|---|

| Material | Polyethylene terephthalate | Cable‑grade PET film |

| Thickness | 12–36 μm | Tailored for mechanical strength |

| Tensile strength (MD/TD) | 150–220 MPa | At room temperature |

| Elongation at break (MD/TD) | 80–140 % | Provides flexibility |

| Heat shrinkage (150 °C / 30 min) | ≤ 2.0 % | Ensures dimensional stability |

| Melting point | ~ 255–260 °C | PET native property |

Composite Laminate Characteristics

| Parameter | Typical Range / Value | Description |

|---|

| Total thickness (AL PET AL) | 30–80 μm | Depends on design |

| Width range | 10–1200 mm | Slit to cable design width |

| Density (composite) | ~ 2.3–2.6 g/cm³ | Based on layer ratio |

| Tensile strength (laminate MD) | ≥ 70–150 MPa | Depends on thickness and alloy |

| Elongation at break (laminate) | ≥ 5–20 % | Tuned via PET and temper |

| Adhesion between layers | ≥ 2.0–4.0 N/15 mm | Peel strength, no delamination |

| Operating temperature range | −40 °C to +85 °C (typical) | Cable‑system dependent |

| Storage temperature | 5 °C to 35 °C | Dry, covered conditions |

Chemical Composition of Typical Aluminum Alloys

Alloy 1235 (High‑Purity Aluminum for Foil)

| Element | Typical Content (wt%) |

|---|

| Al | ≥ 99.35 |

| Si + Fe | ≤ 0.65 |

| Cu | ≤ 0.05 |

| Mn | ≤ 0.05 |

| Mg | ≤ 0.05 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.03 |

| Others (each) | ≤ 0.03 |

Alloy 8011 (Foil‑Grade Aluminum for Enhanced Strength)

| Element | Typical Content (wt%) |

|---|

| Al | Balance |

| Fe | 0.60–1.00 |

| Si | 0.50–0.90 |

| Cu | ≤ 0.10 |

| Mn | ≤ 0.10 |

| Mg | ≤ 0.05 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.08 |

| Others (each) | ≤ 0.05 |

Actual alloy choice and composition are specified according to customer standards, regional norms, and particular cable performance targets.

Shielding and Electrical Performance

While exact shielding performance depends on cable geometry and grounding strategy, typical indicative values for AL PET AL in submarine cable systems are:

| Parameter | Typical Performance (Indicative) |

|---|

| Surface resistivity (AL side) | ≤ 0.03 Ω/sq (depending on thickness) |

| Shielding effectiveness | 40–80 dB (kHz to several MHz range) |

| DC volume resistivity (PET) | ≥ 10¹⁵ Ω·cm |

| Dielectric strength (laminate) | ≥ 2–4 kV (thickness‑dependent) |

For detailed EMI calculations and modeling, laminate data is integrated with cable design (armoring, jacket materials, conductor configuration, and grounding).

Environmental and Reliability Considerations

| Factor | Performance / Recommendation |

|---|

| Salt‑spray resistance | Enhanced with appropriate AL alloy and surface treatment |

| Hydrostatic pressure | Maintains mechanical and barrier properties at deep‑sea pressures |

| Thermal cycling | Low risk of delamination with controlled adhesion systems |

| Chemical compatibility | Compatible with typical cable filling compounds and greases |

| Design life | Suitable for multi‑decade submarine cable service |

Available Customization Options

| Option Category | Examples of Customization |

|---|

| Thickness combination | 12/25/12 μm, 15/23/15 μm, 20/36/20 μm, and others |

| Alloy and temper | 1235‑O, 1235‑H18, 8011‑O, etc. |

| Surface treatments | Primed, chemically treated, or roughened for enhanced bonding |

| Slit width and coil OD | Tailored to specific cable production lines |

| Packaging | Moisture‑protected coils for marine cable factories |

Handling, Storage, and Processing Notes

- Store in a clean, dry, and temperature‑controlled area to prevent condensation and surface corrosion

- Avoid sharp mechanical shocks that might deform coil edges or cause telescoping

- During cable taping, ensure tension control is tuned to avoid wrinkles and maintain tight overlap

- Ground aluminum layers appropriately in the cable design to maximize shielding effectiveness

Why Choose AL PET AL for Submarine Communication Cables

- Combines the electrical shielding of aluminum with the robustness of PET in a single, easy‑to‑process laminate

- Provides long‑term protection and stability under harsh subsea environments, reducing risk of cable failure and signal loss

- Supports modern high‑capacity, long‑haul optical submarine networks where reliability and uptime are critical

Engineered for deep‑sea performance, Double Aluminum Foil with PET Core (AL PET AL) is a material for high‑reliability submarine communication cable designs, delivering a balanced combination of shielding, mechanical strength, and environmental resistance.