Custom Aluminum Foil Jumbo Roll for Air Conditioner Fin Production and Heat Transfer: A Deep-Dive from the Heat’s Point of View

Imagine designing aluminum foil not from the perspective of a rolling mill or a procurement department, but from the perspective of heat itself.

Heat cares about how quickly it can move, how easily it can spread across a fin surface, how little resistance it meets at every microscopic contact point. When viewed from this angle, a custom aluminum foil jumbo roll for air conditioner fin production is no longer just “metal in a coil.” It becomes a highly tuned highway system for thermal energy.

Why Heat Prefers Aluminum Foil Fins

Heat is inherently impatient. It travels from the refrigerant to the tube wall, then to the fin, then to the air. Every delay is a temperature penalty. Aluminum foil fins are designed to keep those delays as short as possible.

From the heat’s point of view, the ideal fin foil:

- Offers minimal thermal resistance from tube to fin and from fin to air

- Spreads heat rapidly away from the tube contact zone across the fin area

- Maintains stable performance over years of condensation cycles, corrosion, and vibration

- Presents a surface that encourages effective condensation drainage and efficient air-side heat transfer

These demands immediately point to specific material requirements: high thermal conductivity, controlled strength and formability, consistent thickness, and carefully engineered surface chemistry.

The Alloy Backbone: What Heat “Sees” Inside the Metal

Every air conditioner fin foil jumbo roll starts with a choice of alloy, and that choice quietly dictates how heat will flow in service.

For air conditioner fin production, the most widely used alloys are from the 3xxx and 1xxx series, with 8xxx occasionally used for specific mechanical or cost-performance balances.

Typical fin foil alloy choices include:

- 1100: Commercially pure aluminum with very high thermal conductivity and good formability, but moderate strength

- 1050 / 1060: High-purity aluminum for maximum thermal conductivity with excellent formability, common where forming complexity is high and mechanical load is low

- 3003: Mn-containing alloy with improved strength, moderate thermal conductivity, and excellent workability, ideal for fins with stronger structural requirements

- 8011: Al–Fe–Si alloy often used when a balance of moderate strength, good formability, and specific surface properties is needed

From a thermal perspective, purity is power: the fewer alloying elements, the higher the thermal conductivity. But heat alone does not design fin material; the manufacturing process and the final application do as well. That is why 3003 and 8011 often win in real-world applications: they trade a small amount of conductivity for better strength, resilience, and handling during fin stamping and corrugation.

Tempering: Teaching Foil How to Deform and How to Hold Its Shape

Once an alloy is chosen, temper is the next major lever. Temper is essentially the “behavioral programming” of the foil: how it responds to deformation, how it springs back, how it resists collapse or tearing during high-speed fin pressing.

Common tempers for air conditioner fin foil include:

- O (Annealed): Soft, maximum ductility, best for deep or complex forming, but lowest strength

- H22 / H24: Strain-hardened and partially annealed for a useful balance of strength and formability

- H18: Fully hard, high strength, but lower formability, generally limited to specific process conditions

When a fin press stamps louvers and corrugations into the foil, heat is silently “watching” how well the fin shape is maintained. If the foil is too soft, the formed louvers collapse slightly, reducing the effective air-side area and degrading heat transfer. If the foil is too hard, it may crack or tear, leading to rejects and micro-defects that disturb air flow and thermal paths.

For this reason, many high-volume air conditioner manufacturers prefer 3003-H24 or 3003-H22 fin foil: strong enough to hold crisp fin geometry, yet soft enough to form complex shapes without catastrophic failure. Where maximum thermal conductivity is the main priority and geometry is simpler, O-temper 1100 or 1050 may be used.

Thickness: The Hidden Trade-off Between Conductivity and Fin Density

Foil thickness is where thermal theory collides with manufacturing economics and coil handling.

From heat’s perspective, thinner is often better. A thinner fin foil allows:

- Higher fin density (more fins per inch or per meter)

- Increased total surface area for air-side heat transfer

- Reduced thermal mass, enabling faster transient response

However, if the foil becomes too thin, it:

- Risks buckling, tearing, or warping during stamping

- Becomes vulnerable to handling damage in fin pack assembly

- May lose some long-term structural stability in aggressive environments

Air conditioner fin foil jumbo rolls are commonly produced in thickness ranges such as:

- 0.08 mm to 0.25 mm for residential and light commercial coils

- Occasionally down to about 0.06 mm in specialized designs, with carefully controlled alloy and temper

- Around 0.10–0.15 mm as a frequently chosen balance for many mainstream applications

From a heat-transfer design perspective, foil thickness is often optimized in combination with fin pitch, louver geometry, and coil depth. The jumbo roll is not just “material supply”; it is a tuning element in the heat exchanger’s thermal circuit.

Surface Condition: Heat’s First Contact with the Air

Thermal conduction inside the metal may be excellent, but if the outer surface of the fin is poorly engineered, the air-side heat transfer coefficient and condensation behavior will waste much of that advantage.

Surface finish and treatment of aluminum foil for AC fins can influence:

- Wetting behavior of condensing water

- Drop-wise versus film-wise condensation

- Water drainage and anti-frost characteristics

- Resistance to corrosion from pollutants and condensate acidity

Fin foil jumbo rolls can be supplied with:

- Plain mill finish for general use

- Hydrophilic coatings to encourage uniform water film formation and rapid drainage, reducing bridge-like water retention that blocks air flow

- Hydrophobic or enhanced-drainage surfaces designed to improve defrosting or reduce frost adhesion in certain environments

- Anti-corrosive coatings tailored for marine or industrial atmospheres

From the heat’s point of view, the best surface is one that prevents stagnant water films and reduces fouling, keeping fin area “alive” for heat transfer over the coil’s lifetime.

Implementation Standards: Translating Thermal Intent into Manufacturing Reality

A custom aluminum foil jumbo roll must satisfy not only the needs of heat transfer, but also international and customer-specific standards that ensure safety, consistency, and interchangeability.

Relevant standards and practices often include:

- Alloy and temper definitions aligned with EN, GB/T, ASTM, or JIS standards, such as ASTM B209 for aluminum and aluminum-alloy sheet and plate

- Dimensional tolerances for thickness, width, and flatness tailored to high-speed fin-press lines

- Surface quality criteria regulating pinholes, roll marks, oil stains, and edge cracks

- Mechanical property ranges ensuring that tensile strength, yield strength, and elongation support the intended fin-forming process

- Corrosion performance tested with salt spray or cyclic environmental aging, especially for outdoor units

- Coating performance requirements (adhesion, thickness, contact angle, water drop test) for hydrophilic or protective surfaces

A custom jumbo roll is usually engineered backward from the fin production line: press speed, die design, louver pattern, and required fin height define the mechanical behavior needed. This is then matched with alloy-temper selection, finishing, and quality control standards.

Mechanical and Thermal Parameters: What the Coil “Promises” to the Heat Exchanger

For an air conditioner fin producer, typical parameters specified for a custom aluminum foil jumbo roll may include:

- Alloy designation: 3003, 1100, 1050, 8011, or customized variants

- Temper: O, H22, H24, H18, depending on forming and strength needs

- Thickness range and tolerance: for example, 0.10 mm ± 0.005 mm

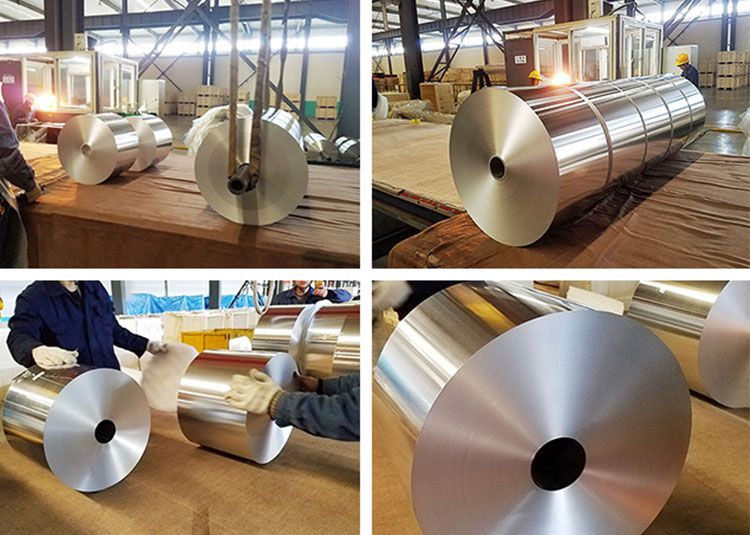

- Width: matched to fin press specifications, often 300–1,500 mm for jumbo rolls

- Tensile strength and yield strength: defined windows to balance formability and rigidity

- Elongation: minimum percent to prevent cracking in heavily formed zones

- Surface roughness: controlled Ra to optimize coating adhesion or surface performance

- Coating type and thickness (if applied): hydrophilic, anti-corrosive, or hybrid systems

- Coil inner and outer diameter, coil weight: optimized to minimize line stoppages and ensure stable unwinding

These parameters are not independent; changing one often demands a compensating adjustment elsewhere. For instance, a fin design requiring ultrafine louvers at high line speed might push for slightly higher strength (H24) and tighter thickness tolerance, but this may require a modest change in alloy composition or final annealing schedule to retain acceptable elongation.

Chemical Composition: The Microstructure That Guides Heat and Strength

At the core of every property lies the chemistry. The trace elements in aluminum fin foil either open or close pathways for both electrons and phonons—the carriers of heat.

Below is a representative chemical composition table for commonly used fin foil alloys (typical ranges, actual production may be fine-tuned within standard limits):

Typical Chemical Composition of Common Air Conditioner Fin Foil Alloys (wt%)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others (each) | Others (total) | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.10 | ≥99.50 |

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.10 | ≥99.60 |

| 1100 | ≤0.95* | Included in Si+Fe* | 0.05–0.20 | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.05 | ≤0.05 | ≤0.15 | Balance |

| 3003 | ≤0.60 | ≤0.70 | ≤0.20 | 1.0–1.5 | ≤0.10 | ≤0.10 | ≤0.05 | ≤0.05 | ≤0.15 | Balance |

| 8011 | 0.50–0.90 | 0.60–1.0 | ≤0.10 | ≤0.10 | ≤0.10 | ≤0.10 | ≤0.08 | ≤0.05 | ≤0.15 | Balance |

* For 1100, Si + Fe together ≤ 0.95 typically

In high-purity alloys like 1050 and 1060, the minimal presence of alloying elements keeps thermal conductivity high, which heat “likes.” In 3003, manganese additions introduce solid solution and dispersoid strengthening, reducing conductivity somewhat but improving structural stability and resistance to localized deformation and fatigue.

8011, with controlled Si and Fe, offers better stiffness and specific processing advantages, especially where foil needs a little more rigidity without moving into drastically different alloy families.

Micro-Engineered for Fin Production: How Jumbo Rolls Behave on the Line

On a modern fin production line, the jumbo roll is continuously uncoiled, straightened, lubricated, stamped, slit, and stacked. The material passes through rapid cycles of bending, stretching, and local shearing—thousands of times per minute.

To heat, this looks like infrastructure being laid at high speed. Every louvered fin that emerges defines an eventual micro-pathway for thermal energy to migrate from tube to air. The roll has to meet several subtle but critical behavioral expectations:

- Consistent yield strength to avoid fluctuating louver heights and fin pitches

- Controlled grain size for uniform deformation, avoiding localized thinning or orange peel

- Minimal residual stress to prevent fin twist or coil “memory” that interferes with stacking

- Stable lubricity through coordinated rolling oil and cleaning/coating processes, enabling clean, precise stamping without picking or galling

This is where custom production really matters. A generic foil may meet basic mechanical numbers but still behave inconsistently on a specific high-speed fin line. A truly customized jumbo roll is tuned not just to a specification sheet, but to a particular set of dies, line speeds, lubrication regimes, and coil handling logistics.

Corrosion and Lifetime Thermal Performance: Keeping Heat Paths Open for Years

An air conditioner rarely operates in a pristine laboratory environment. Outdoor units especially face a mix of:

- Acidic rain and atmospheric pollutants

- Coastal salt-laden air

- Dust, organic debris, and biological growth

- Cyclic wet–dry conditions and mechanical vibration

From heat’s perspective, corrosion is the slow closing of once-wide highways. Pitting, oxide growth, and accumulation of deposits all create local bottlenecks.

To mitigate this, fin foil jumbo rolls can incorporate:

- Alloys with better corrosion resistance, such as 3003 over many years of practice

- Hydrophilic coatings that accelerate water drainage and reduce corrosive residue residence time

- Anti-corrosive topcoats or primers to delay onset of pitting and galvanic reactions with adjoining metals

- Carefully controlled surface cleanliness from production, minimizing residual chlorides or contaminants that might accelerate corrosion under wet films

The result is not only longer life, but a slower decline in seasonal energy efficiency ratio (SEER) as the unit ages. In other words, well-engineered foil turns early-life efficiency into long-term performance.

From Raw Roll to Energy Efficiency: The Invisible Value Chain

When you adjust the thermostat, you rarely think about the alloy series, temper condition, or micro-level surface chemistry of the aluminum foil fins inside your air conditioner. But from the heat’s point of view, those details are everything.

A custom aluminum foil jumbo roll for fin production is essentially a pre-configured energy management tool, designed to:

- Accept heat quickly from the refrigerant-side tube

- Spread that heat efficiently along the fin

- Share it aggressively with the passing air

- Maintain this performance steadily through years of environmental attack and mechanical stress

By looking at the material from heat’s own perspective, the usual engineering choices—3003 vs. 1100, O vs. H24, 0.10 mm vs. 0.15 mm, coated vs. uncoated—become much clearer and more strategic.

In competitive HVAC markets, where small improvements in efficiency and lifetime performance translate into strong differentiation, the right custom aluminum foil jumbo roll is not just a consumable. It is a core design element of the heat exchanger itself—a silent, highly engineered partner in every degree of cooling delivered.