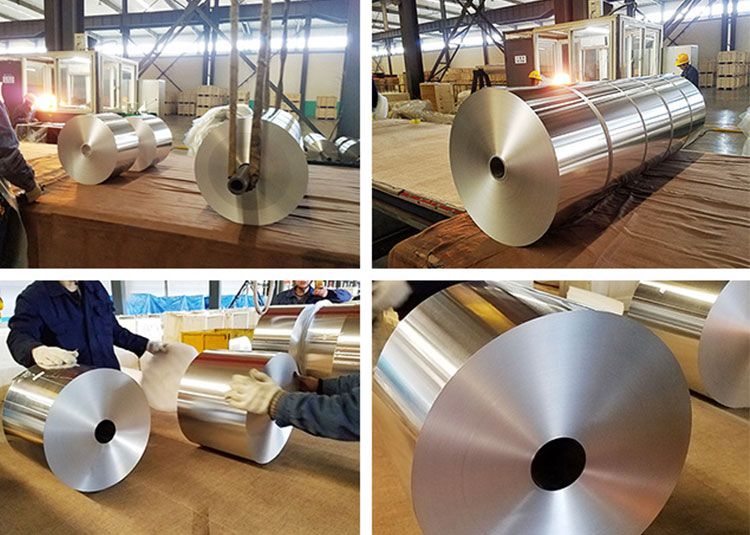

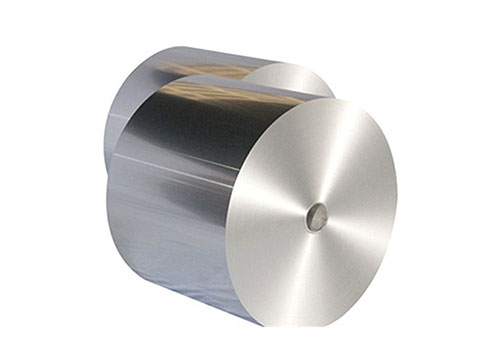

Alloy 8011 3003 Aluminum Foil

09/19 2025 Lucy

Aluminum foil is a versatile and widely used product has features such as pliability, light weight, impermeability to gases, and an exceptional ability to resist moisture and contamination. Among the different alloys of aluminum foils, Alloy 8011 and Alloy 3003 are particularly renowned for their excellent properties making them ideal for various applications.

Features

Alloy 8011

- High Tensile Strength: Offers tailored mechanical strength suitable for diverse applications.

- Resistance to Corrosion: Excellent resistance to oxidation enhances longevity.

- Good Formability: Can be shaped easily allowing for innovative packaging solutions.

Alloy 3003

- Good Workability: High ductility enabling complex shapes without damage.

- Corrosion Resistance: Naturally resistant to rust and other saturation reactions.

- Formidable Thermal Conductivity: Excellent conductor of heat which is advantageous in specific applications.

Applications

- Food Packaging: Both alloys serve effectively in food wrapping, providing sealing properties, preventing moisture loss, and preserving freshness.

- Pharmaceuticals: The pharmaceutical industry uses these alloys to manufacture blister packs, ensuring medication stability and protection.

- Insulation: An ideal choice for thermal insulation applications progressively more common in construction and HVAC systems.

- Electrical Components: Alloy 3003 is used for making electrical components due to its electrical and thermal conductivity properties.

Technical Specifications

Chemical Composition

| Alloy | Aluminum (Al) | Iron (Fe) | Silicon (Si) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Zinc (Zn) | Titanium (Ti) | Other Elements |

|---|

| 8011 | 88.0 – 92.0% | ≤0.50% | ≤0.30% | ≤0.01% | 0.5% min. | - | - | ≤0.15% | Various Impurities ake. |

| 3003 | 95.0% min. | 0.12 - 0.5% | 0.50% max. | 0.05 - 0.20% | Manganese 1.0 - 1.5% | - | 0.10% max. | 0.05% max. | Various Impurities & fabrication aids. |

Technical Data

| Property | Alloy 8011 | Alloy 3003 |

|---|

| Thickness | 0.006 - 0.020 mm | 0.006 - 0.020 mm |

| Width | 200 - 1550 mm | 200 - 1550 mm |

| Strength (Yield, min MPa) | 110 | 95 |

| Ultimate Tensile Strength (MPa) | 130 – 195 | 100 – 145 |

| Elongation | ≥3% | ≥18% |

| Annealing Temperature | 400°C - 500°C | 300°C - 450°C |

| Density (g/cm³) | 2.7 | 2.73 |

| Thermal Conductivity (W/m.K) | 220–250 | 235 |

Mechanical Properties

Mechanical Properties for Common Temperatures

| Alloy | Temperatures (°C) | Tensile Strength (MPa) | Elongation (%) | Hardness Brinell |

|---|

| 8011 | Room Temperature | 130 – 195 | ≥3% | 55-85 |

| 3003 | Room Temperature | 100 – 145 | ≥18% | 58-95 |

3003

8011

https://www.aluminum-sheet-metal.com/a/alloy-8011-3003-aluminum-foil.html

Related Products

Mainly used in construction ,decoration ,packing ,printing, cover material ,piping, electronic, elements, refrigeration, air condition, automobile ,etc.

Related Blog