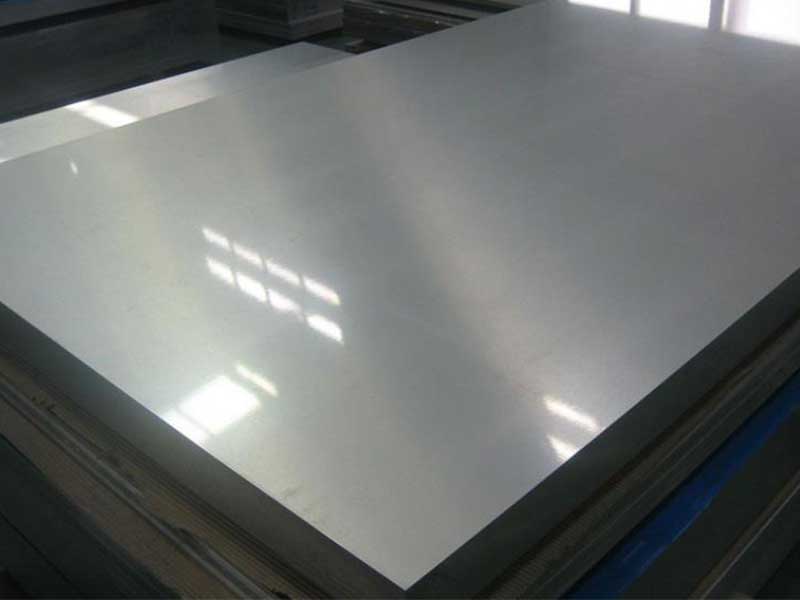

The 1050 Aluminum Sheet, available in both DC (Direct Chill) and CC (Continuous Cast) forms, is a highly versatile metal sheet known for excellent corrosion resistance, good conductivity, and superior workability. It is widely used in industries seeking lightweight yet durable materials for manufacturing, construction, and household applications.

What is 1050 DC or CC Aluminum Sheet?

The 1050 aluminum sheet typically refers to an aluminum alloy with a minimum 99.5% aluminum content, placing it in the 1xxx series, celebrated for exceptional corrosion resistance, excellent electrical and thermal conductivity, and high ductility.

- DC (Direct Chill) Casting: Features a casting process where molten metal solidifies via chilling water to form ingots with superior surface quality. DC sheets usually have better machinability and can be produced in thicker gauges.

- CC (Continuous Casting): Involves continuously casting while the molten metal solidifies during a downward passage through a mold producing thinner sheets with generally uniform thickness and high surface finish.

Functions & Features

- Outstanding Corrosion Resistance: Ideal for humid and corrosive environments.

- Excellent Workability and Formability: Easily fabricated, suited for bending, rolling, stamping, and welding.

- Superior Electrical and Thermal Conductivity: Common in electrical fittings and heat exchangers.

- Non-toxic & Recyclable: Safe for food and pharmaceutical containers and eco-friendly reuse.

Common Applications

| Application Area | Typical Use |

|---|---|

| Electrical Components | Busbars, capacitors, wiring splices due to excellent conductivity |

| Packaging Industry | Foil wraps, pharmaceutical blister packs, cans – thanks to non-toxicity and purity |

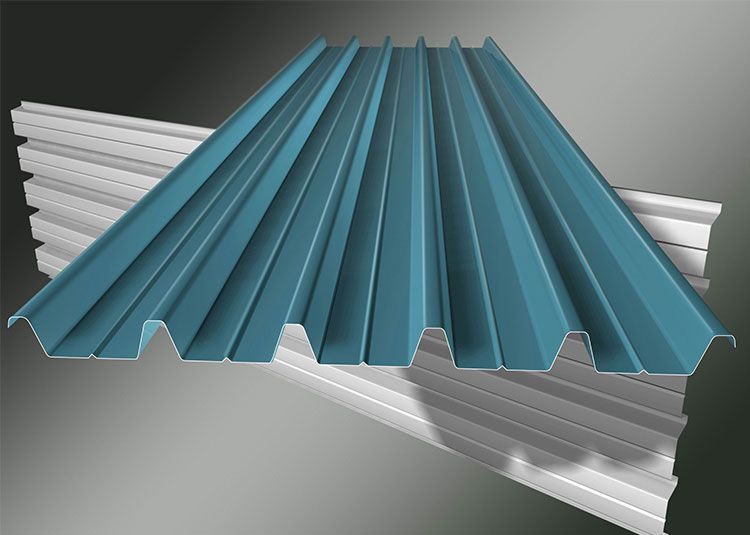

| Construction & Architecture | Roofing, cladding, gutters, and decorative trim owing to corrosion resistance and light weight |

| Automotive and Aviation | Heat exchangers, decorative elements, and paneling |

| Household Appliances & Utensils | Cookware, panels, utensils, experience no chemical interaction and rust resistance |

| Reflective Surfaces | Solar reflectors, lighting fixtures where bright and reflective faint surface’s advantageous |

Chemical Composition (According to GB/T 3880-2006)

| Element | Al | Si (Max) | Fe (Max) | Cu (Max) | Mn (Max) | Mg (Max) | Zn (Max) | Ti (Max) | Others (Max) |

|---|---|---|---|---|---|---|---|---|---|

| Percentage (%) | ≥99.5 | 0.25 | 0.40 | 0.05 | 0.03 | 0.03 | 0.10 | 0.03 | 0.15 |

Mechanical Properties and Temper Designations

Temper Designations

| Temper | Description | Common Use |

|---|---|---|

| O | Annealed | Maximum ductility and softness |

| H12 | Half-Hard (Non-annealed) | Good hardness and strength |

| H14 | Quarter Hard | Higher strength with moderate ductility |

| H16 | Hard cold working | High strength with less ductility |

Mechanical Properties (Typical Values)

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| O | ≥ 70 | ≥ 20 | ≥ 35 |

| H12 | 90 - 110 | 40 - 90 | ≥ 10 |

| H14 | 105 - 125 | 55 - 105 | ≥ 6 |

| H16 | 125 - 145 | 70 - 115 | ≥ 3 |

Standards and Implementation

| Standard | Description | Geographic Scope |

|---|---|---|

| GB/T 1199-2015 | Aluminium and aluminium alloys – sheets | China |

| ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy sheet and Plate | USA |

| EN 485-2 | Aluminium and aluminium alloys, sheet, strip and plate mechanical properties | Europe |

| ISO 6361 | Wrought aluminium and aluminium alloy sheet and strip | International |

1050 DC or CC Aluminum Sheet is an indispensable solution with its incredible combination of purity, longevity, and functional advantage due to the choice of cast process. It excels in corrosion resistance, formability, and conductivity, suitable for applications in electrical, construction, pharmaceutical, and various industrial sectors.

Adopting the right temper and configurable size and thickness options based on the casting method (DC or CC), this alloy sheet remains the top choice for professionals and manufacturers looking for dependable quality materials.

For more information about our 1050 DC or CC Aluminum Sheets, licensing, and ordering, contact our sales team or request a detailed specification datasheet today!