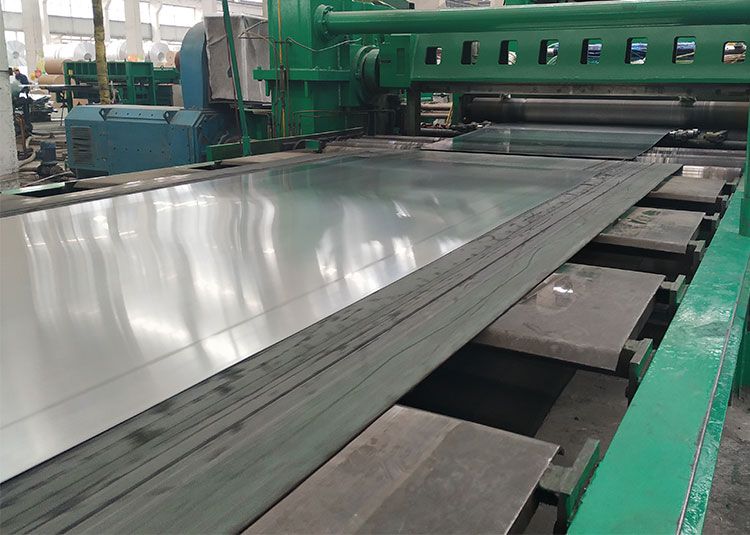

Aluminum sheets are widely recognized for their versatility and high performance in various industries. Among these, the 0.8mm thick polished aluminum sheet stands out due to its unique properties that make it suitable for a range of applications.

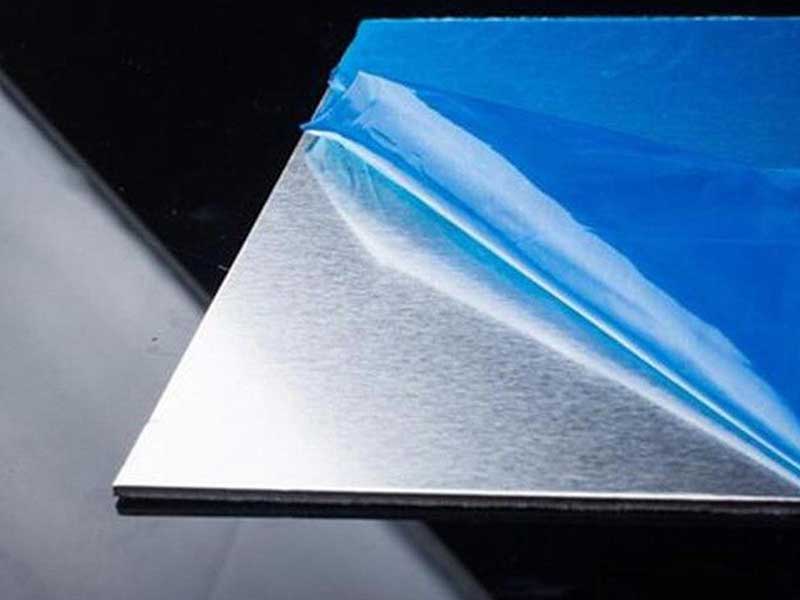

What is a Polished Aluminum Sheet?

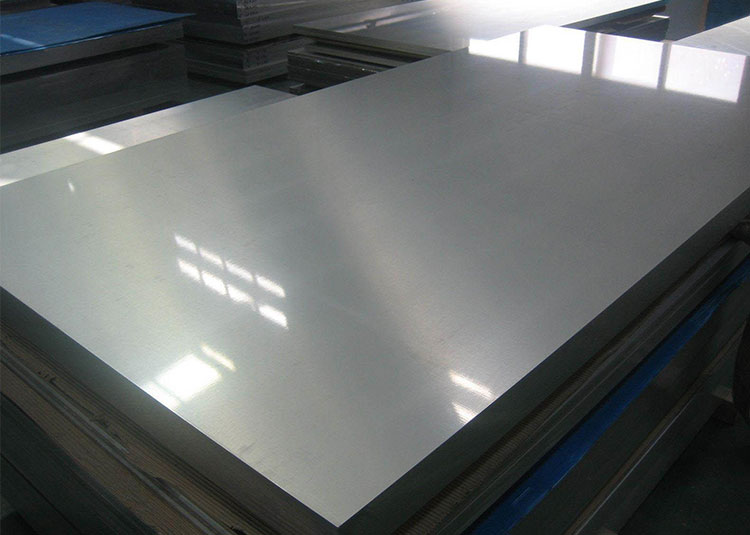

A polished aluminum sheet is an aluminum sheet that has been carefully processed and polished to achieve a shiny, mirror-like surface. This type of finish enhances the aesthetic appeal while maintaining the material's strength and lightweight characteristics.

Functions of 0.8mm Thick Polished Aluminum Sheet

The 0.8mm thickness provides several advantages:

- Lightweight: Lower weight than many other materials.

- Corrosion Resistance: Offers longer service life, especially in challenging environments.

- Aesthetic Appeal: Its polished surface enhances visual aesthetics, perfect for consumer applications.

- Thermal Conductivity: Great for heat dissipation in various applications, including HVAC systems.

Parameters

When considering the purchase of polished aluminum sheets, it's essential to keep the following parameters in mind:

| Parameter | Value |

|---|---|

| Thickness | 0.8mm |

| Width | Customizable |

| Length | Customizable |

| Finish | Mirror Polish |

| Standard | ASTM B209 |

| Alloys typically used | 1050, 5083, and 6061 |

Applications

The applications of the 0.8mm thick polished aluminum sheet are vast, thanks to its unique characteristics. Common uses include:

Test Equipment: Due to its strength-to-weight ratio, it is commonly used in manufacturing test equipment.

Decorative and Architectural Uses: The dazzling finish is ideal for decorative architectural elements such as panels and cladding.

Automotive Trim: Often used as a trim piece requiring good reflections or decorative qualities.

Food and Beverage Packaging: Lightweight and providing good barrier properties against moisture and light.

Lighting Fixtures: Excellent thermal and reflectivity properties allow effective heat dispersion.

Technical Specifications

the specifications of the welded aluminum sheet can further support its effective use. Below is a detailed look at the technical specs, which help clarify its capabilities and ideal uses.

Chemical Composition

Below is a table showing the typical chemical composition of commonly used alloys in polished aluminum sheets:

| Alloy | Aluminum (Al) | Magnesium (Mg) | Silicon (Si) | Iron (Fe) | Others cum. (%) |

|---|---|---|---|---|---|

| 1050 | 99.5% | 0.05-0.2% | 0.25% | 0.4% | 0.1% |

| 5083 | 92.0% | 3.0-4.0% | 0.3% | 0.4% | 0.5% |

| 6061 | 94.0-98.0% | 0.8-1.2% | 0.4-0.8% | 0.7% | 0.8% |

Technical Parameters

| Parameter | Specifications against common industry standards |

|---|---|

| Melting Point | Approximately 660 °C (1220 °F) |

| Density | 2.70 g/cm³ |

| Yield Strength | 40-650 MPa across common alloys |

| Tensile Strength | 90-300 MPa across common alloys |

| Elongation | 12-60% across common alloys |

| Hardness (Brinell) | 30-138 HB |

Tempering Conditions

Temper refers to the treatment of aluminum to adjust its mechanical properties:

- F: As-fabricated

- H: Strain-hardened

- O: Annealed

- T1, T2, …, T8: Solution heat-treated and artificially aged

Implementation Standards

Various standards influence the working and testing of aluminum sheet products, particularly:

- ASTM B209: Specification for Aluminum and Aluminum-Alloy Flat Sheet

- ASTM B221: Specification for Aluminum-Alloy Extruded Bars, Rods, Wires, Profiles, and Tubes

- ISO 9001: International standard to ensure consistent quality management systems