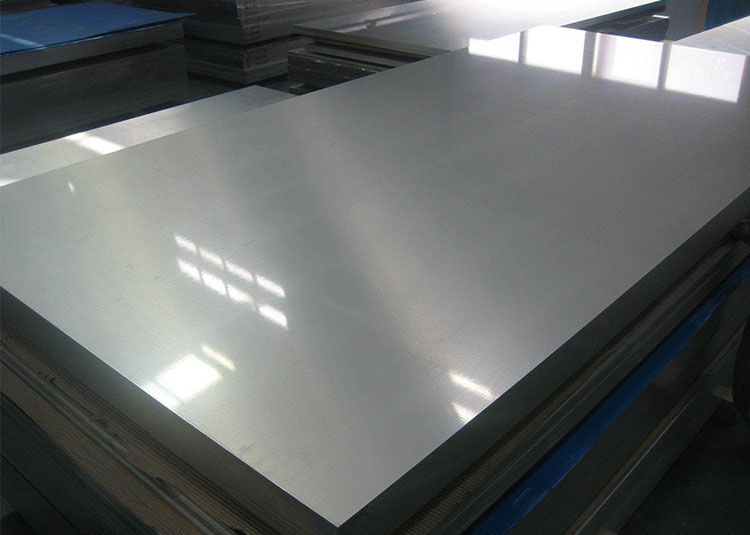

Aluminum, a lightweight yet remarkably robust metal, has transformed modern industry with its unique combination of properties. From aerospace to architectural marvels, underwater exploration vehicles to kitchen utensils, aluminum serves crucial functions, thanks to its material characteristics and adaptable alloy variants.

Aluminum’s Core Properties

Aluminum (Al), atomic number 13, is known for its excellent strength-to-weight ratio, corrosion resistance, and high thermal and electrical conductivity. It boasts a density of about 2.7 g/cm³, significantly lighter than steel (~7.85 g/cm³), making it ideal for weight-sensitive applications. Its malleability and ductility are further enhanced through alloying and thermo-mechanical treatments, enabling both intricate shapes and rugged structural components.

Chemical Composition and Properties

Aluminum in its pure form exceeds 99% aluminum content, but for industrial purposes, it’s often alloyed with elements such as silicon (Si), magnesium (Mg), copper (Cu), and zinc (Zn). These alloys impact mechanical strength, corrosion resistance, and workability. Below is a standard chemical composition table (Wt%) for major aluminum alloy series, which guide designers when selecting material for targeted functions.

| Alloy Series | Alloying Elements | Typical Composition Range (Wt%) |

|---|---|---|

| 1xxx | 99% min Pure Aluminum | Al: 99.0+; Si, Fe, Cu each <0.3% |

| 2xxx | Copper (Cu) | Cu: 3.5–5.5%; Mg: 0.2–1.5%; Fe, Si <1% |

| 3xxx | Manganese (Mn) | Mn: 1.0–1.5%; Si <1.0%; Fe <0.7% |

| 4xxx | Silicon (Si) | Si: 4.0–6.0%; Cu, Mg <0.3% |

| 5xxx | Magnesium (Mg) | Mg: 3.0–5.0%; Si <0.4%; Fe <0.5% |

| 6xxx | Magnesium (Mg) + Silicon (Si) | Mg: 0.8–1.2%; Si: 0.4–1.2%; Fe <0.5% |

| 7xxx | Zinc (Zn) | Zn: 5.0–8.0%; Mg: 1.5–2.5%; Cu: 1.2–2.0% |

Alloy Tempering: Tailoring Aluminum's Mechanical Properties

The versatility of aluminum sheets notably improves with tempering — heat treating and mechanical working protocols that enhance specific mechanical properties. The most commonly used temper designations follow ASTM and AMS standards such as:

| Temper Code | Condition | Description | Mechanical Property Impact |

|---|---|---|---|

| O | Annealed | Softest condition; maximum ductility | Tensile strength: Low; high elongation |

| H1x | Strain-hardened (non-heat-treated) | Various hardening by cold working | Increased strength; slight reduction in ductility |

| H2x | Strain hardened + partial anneal | Moderated strength | Balanced strength and ductility |

| H3x | Strain hardened + stabilized | Minimal residual stresses | Resistance to dimensional changes |

| T3 | Solution heat treated + cold worked | Moderate strength with good toughness | Good strength, bending characteristics |

| T6 | Solution heat treated + artificial aging | Peak strength | Tensile strength maximized; slightly lower ductility |

These tempers are selectively implemented depending on the end-use. For instance, aerospace components often utilize 7075-T6 alloy that exhibits high tensile strength over 500 MPa, whereas architectural panels prioritize corrosion-resistant 3003-H14 for durability in outdoor environments.

Implementation Standards Governing Aluminum Applications

Global standards ensure consistency and safety in aluminum utilization. The most commonly referenced include:

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate members specifically covering products heavier than 0.016 inch thickness. It guides the mechanical properties, dimensions, and alloy types relevant in applications such as cladding panels.

- AA (Aluminum Association) Designation System: Helps define compositions by series numbers, empowering engineers to select appropriate alloys swiftly.

- AMS 2770: Aerospace Material Specification outlining aluminum alloy sheet tempering and heat treatments.

- ISO 6361: For Wrought aluminum and aluminum alloy sheets, strips and plates, prevalent in automotive design.

Functional Applications of Aluminum Sheets: A Technical Survey

Aerospace EngineeringAluminum provides the skeletal framework in aircraft fuselages, wings, and engine components. For this, alloys like 2024 and 7075 are prevalent because of their favorable strength and fatigue resistance combined with sodium corrosion treatment or anodizing surface protection enhancing lifespan.

Automotive SectorThe push for lighter vehicles to enhance fuel efficiency universalizes aluminum sheet use. Alloy 5000 series (like 5052-H32) balances corrosion resistance against impact loads, forming panels, bodies, and heat exchangers due to superb workability.

Architectural Facades and RoofingSoft architectural sheet aluminum alloys such as 3003 and 3105 facilitate forming beauty along with strength and weather resistance. They undergo coatings or anodizing in compliance with ASTM B221 and AAMA specifications enhancing lifecycle.

Electrical and Thermal ApplicationsThermal conductivity (~237 W/m·K) of certain aluminum alloys supports usage in heat sinks, roof insulation panels. Regarding electrical, high-purity 1350 alloys underpin overhead power cables.

Packaging and Consumer GoodsAluminum’s barrier properties against moisture, light, and oxygen make alloys 1235 or 1145 choice materials in food packaging foil, beverage cans balancing malleability and purity standards defined by FDA.

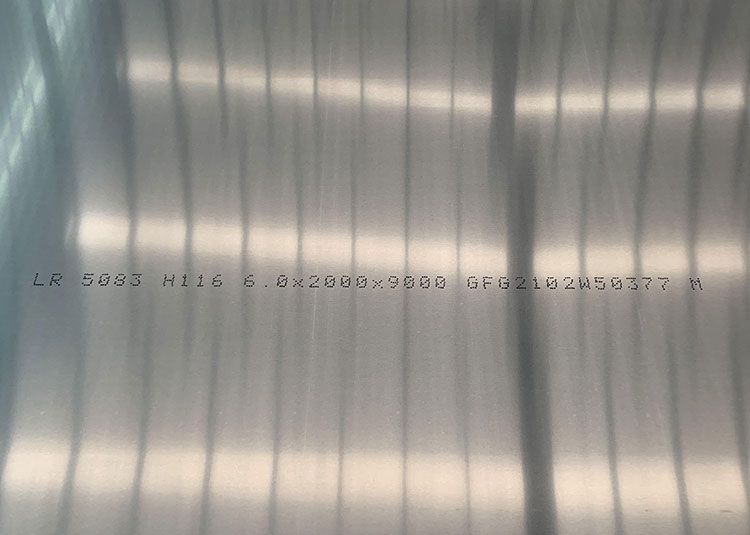

Marine ComponentsSaltwater corrosion isn’t trivial in marine environments; 5000 series Al-Mg alloys (5052, 5083) paired with higher tempers combined with anodization are prevalent to safeguard durability of ship hulls and offshore structures.