Detailed Introduction of Pure Aluminum Plate: Engineering Simplicity Meets Versatility

When it comes to metals in the industrial and commercial landscape, aluminum stands out as a material balancing brilliance between lightweight performance and corrosion resistance. Diving deeper, the pure aluminum plate – often overlooked in favor of its alloyed siblings – offers unique properties and roles worth from a design and sustainability-oriented viewpoint.

What Makes a Pure Aluminum Plate?

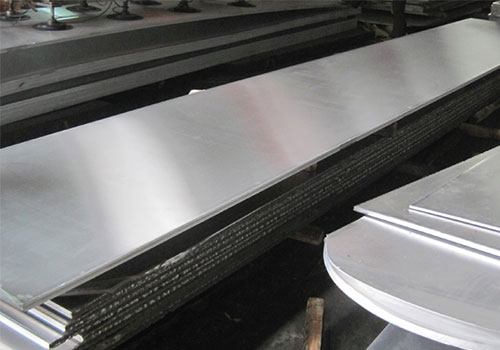

Pure aluminum plates are composed of exceptionally high aluminum content, typically 99% or higher, possessing minimal alloying elements. Unlike the various aluminum alloys devised to enhance strength or conductivity, pure aluminum prioritizes ductility, corrosion resistance, and a naturally high thermal and electrical conductivity.

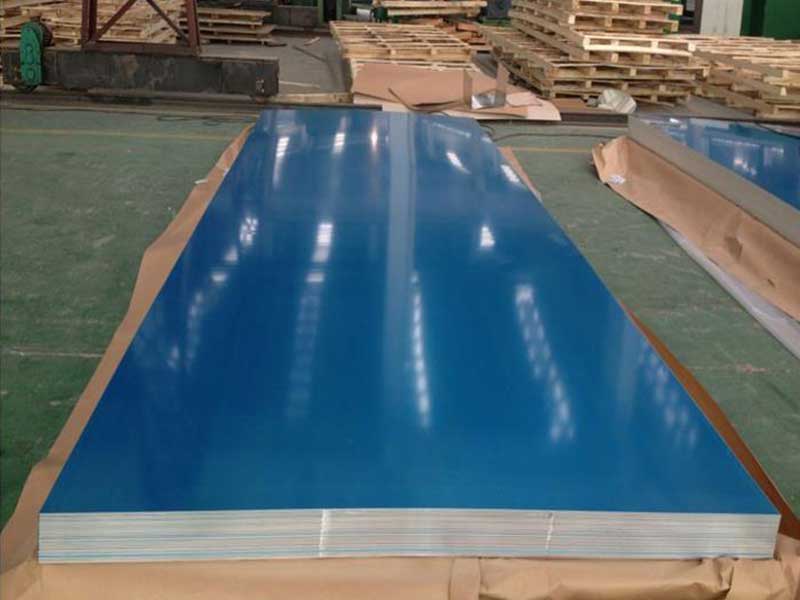

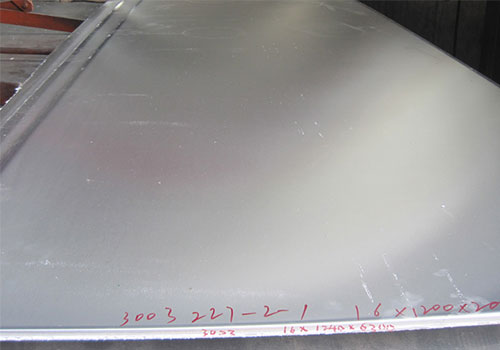

Working on the production line for pure aluminum plate, I've gained a deep appreciation for its deceptively simple nature. While it might seem just a flat sheet of metal, the nuances are critical. The purity itself, measured in terms of percentage of aluminum, directly impacts its properties. A higher purity translates to enhanced corrosion resistance, improved electrical conductivity, and greater formability – essential for applications demanding impeccable surface finishes or intricate designs. We meticulously monitor the alloying process to ensure consistent purity, and even slight variations can affect the final product's suitability for different uses, from food packaging to aerospace components. The seemingly minor imperfections – subtle variations in thickness, minor surface blemishes – are constantly scrutinized, underscoring the high precision demanded by our clients.

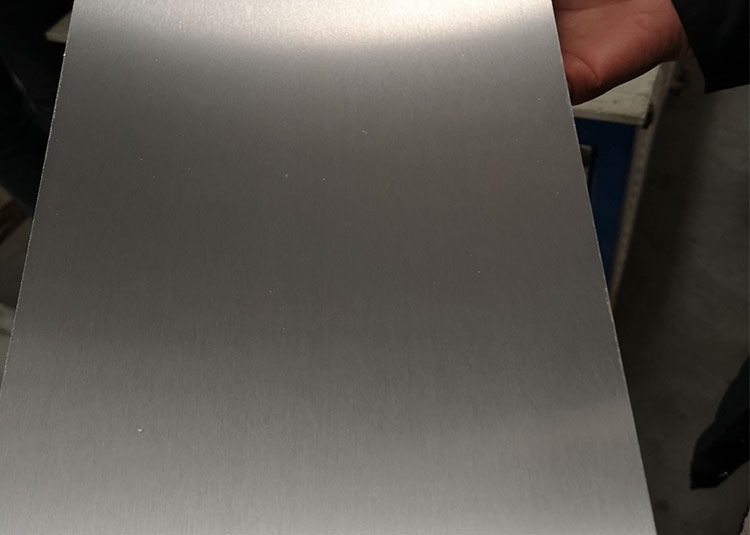

Beyond the technical specifications, there's a certain artistry to working with pure aluminum plate. Watching the raw material transform from ingots to gleaming sheets through rolling and annealing is fascinating. The subtle changes in sheen, texture, and even the sound the metal makes during processing give hints about its quality. It's not just about meeting standards; there's a sense of pride in producing a material that's both incredibly versatile and surprisingly delicate. its behavior under different conditions – how it reacts to heat treatments, the specific tooling needed for efficient forming – is a constant learning process that makes the job both challenging and rewarding.

The uncompromised purity results in a noticeably soft, malleable sheet that can be effortlessly fabricated, bent, or formed. This malleability opens doors for applications requiring precision shaping without the trade-offs introduced by alloying metals like copper, magnesium, or zinc.

Engineering Efficiency Through Pure Simplicity

From an engineering perspective, pure aluminum plate can be likened to a minimalist’s approach in design: less is more. Because its intrinsic conductive ability is near-optimal, it often serves as the foundation for components in electronics where heat dissipation or electric current carriage requires utmost reliability.

In sectors focused on sustainability, the ease of recycling pure aluminum surpasses that of complex alloys. The simpler the composition, the lower the energy consumption and material processing effort needed recycling, reducing carbon footprints significantly.

Beyond Physical Properties: Environmental and Practical Synergy

Consider a construction project utilizing pure aluminum plates for cladding or fixtures. Apart from structural advantages — corrosion resistance prolonging maintenance frequency — the clean, aesthetically pleasing natural silver metallic sheen subtly enhances architectural appeal without added coatings.

An often-underestimated point of pure aluminum is its compatibility with dissimilar materials, minimizing galvanic corrosion risks. This benefit allows creative engineers and architects freedom in combining materials, amplifying functional and aesthetic synergies.

Where You See Pure Aluminum Plates in Action

- Chemical processing equipment: thanks to its impervious surface against most chemicals.

- Electrical transmission: pure plates conduct electricity efficiently with minimal resistance or power loss.

- Reflective surfaces and heat exchangers: they leverage the metal’s capability for heat management and reflective light qualities.

Final Thoughts

Pure aluminum plate offers a distinctly harmonious balance between functional engineering and elegant simplicity. Although industrial innovation often touts heavily alloyed metals, returning our focus to pure aluminum plates reintroduces principles of refinement and sustainability that remain critical in modern product design and eco-conscious manufacturing strategies.