Aluminum coils and strips stand as foundational materials across multiple industries—from automotive manufacturing and packaging to electrical and construction applications. While often overshadowed by finished product applications, these raw aluminum formats possess unique technical attributes that define their versatility and efficiency. In this detailed exploration, we uncover the critical parameters, alloy tempering conditions, implementation standards, and chemical properties that elevate aluminum coils and strips as indispensable components in modern engineering and manufacturing.

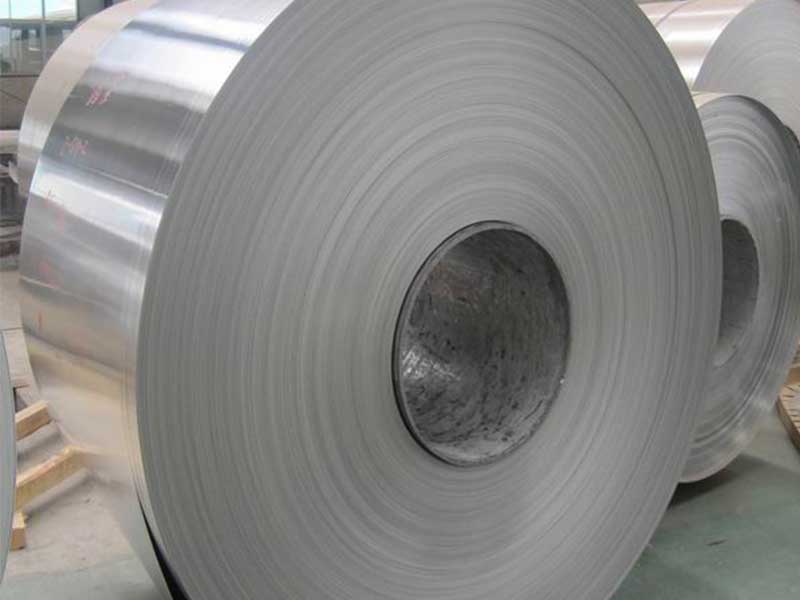

Aluminum Coils and Strips: More than Just Thin Metal Sheets

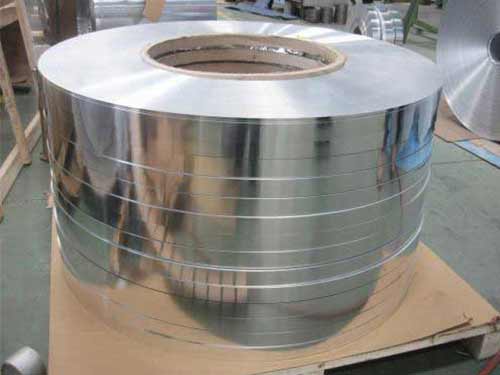

At their essence, aluminum coils are continuous rolls of thin aluminum layer wound onto a spool, whereas aluminum strips refer typically to narrower sectioned forms cut transverse to the coil. This continuous coil structure allows for efficient material handling, storage, and transportation, while the subsequent chopping into strips meets precise dimensional and application needs.

Technical Parameters and Precision Requirements

Several parameters dictate the quality and applicability of aluminum coils and strips:

- Thickness: Typically ranging from 0.2 mm to 3 mm, thickness directly impacts strength, flexibility, and weight.

- Width: The width is customizable, often between 5 mm to 1500 mm.

- Tolerance: Dimensional tolerance is tight to ensure consistency; generally ±0.02 mm for thickness.

- Surface finish: Can be bright, matte, or include protective coatings suited for corrosion resistance, forming quality, or printability.

Critically, these parameters fluctuate dependent on alloy composition and temper conditions.

Gab Through Implementation Standards: Assuring Performance & Quality

Firms manufacturing aluminum coils and strips routinely comply with various international standards to guarantee product reliability and performance uniformity.

Prominent specifications include:

- ASTM B209: Covers aluminum and aluminum-alloy sheet and plate.

- EN 485-2: European standards outlining mechanical properties and dimensions for fabricated aluminum and aluminum alloys.

- JIS H4100: Japanese Industrial Standards specifying aluminum flat products.

- GB/T 3880: Chinese standard commonly adopted by leading Chinese suppliers.

These standards detail acceptable values for mechanical strengths, chemical composition ranges, surface finishes, and tempering conditions—ensuring that coils and strips conform to required application demands globally.

Alloy Types and Chemical Properties: The Building Blocks of Performance

Aluminum coils and strips are produced from a variety of wrought aluminum alloys. The most ubiquitous series are:

| Alloy Series | Typical Alloy | Primary Alloying Elements | Characteristics |

|---|---|---|---|

| 1xxx Series | 1100 | ≥99% Al (commercially pure) | Excellent corrosion resistance, high thermal & electrical conductivity |

| 3xxx Series | 3003 | Mn (1.0-1.5%) | Good corrosion resistance, moderate strength |

| 5xxx Series | 5052 | Mg (2.2-2.8%) | Higher strength, good weldability, excellent corrosion resistance |

| 6xxx Series | 6061 | Mg & Si (~1%) | Medium strength, good corrosion resistance and machinability |

| 8xxx Series | 8011 | Fe, Li compounds | Specialized uses like packaging foil |

A typical chemical composition table for 5052 Alloy (per ASTM B209) illustrates how elemental content regulates material properties:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance (95.0 - 97.5) |

| Magnesium (Mg) | 2.2 - 2.8 |

| Chromium (Cr) | 0.15 - 0.35 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Manganese (Mn) | ≤ 0.1 |

| Silicon (Si) | ≤ 0.25 |

Tempering specifies the heat-treatment and work-hardening state of aluminum coils and strips, significantly dictating their mechanical properties. Temper designations commonly seen include:

- O temper: Annealed, soft state offering peak ductility ideal for forming.

- H series (H1x, H2x, H3x): Strain hardened by cold rolling without thermal treatments.

- T series (T4, T6, T651): Solution heat-treated and artificially aged to maximize strength.

For example, 6061-T6 aluminum strip provides excellent yield strength (~290 MPa) and tensile strength (~310-350 MPa) suitable for structural applications, while 1100-O aluminum coil features excellent forming behavior yet lower strength (~40-60 MPa tensile).

Selecting alloy temper depends heavily on application—balancing ductility for forming and tensile strength for load-bearing.

Applications: Why Technical Precision is Critical

Precision in coil and strip production secures performance reliability where even minute dimensional or compositional variations cause component failures or fabrication difficulties.

- In aerospace, tight dimensional tolerance and defined temper states influence aerostructure strength-to-weight fractions.

- The automotive sector leverages 5xxx series strips for corrosion-resistant body panels.

- Sensitive electrical cables require 1xxx series high conductivity coils.

- Packaging foil, typified by ultra-thin 8xxx series strips, needs precise thickness and surface finish control for product protection.