In the aluminum factory or the application process, sometimes the situation on the aluminum sheets above the situation, for this situation is how is it?

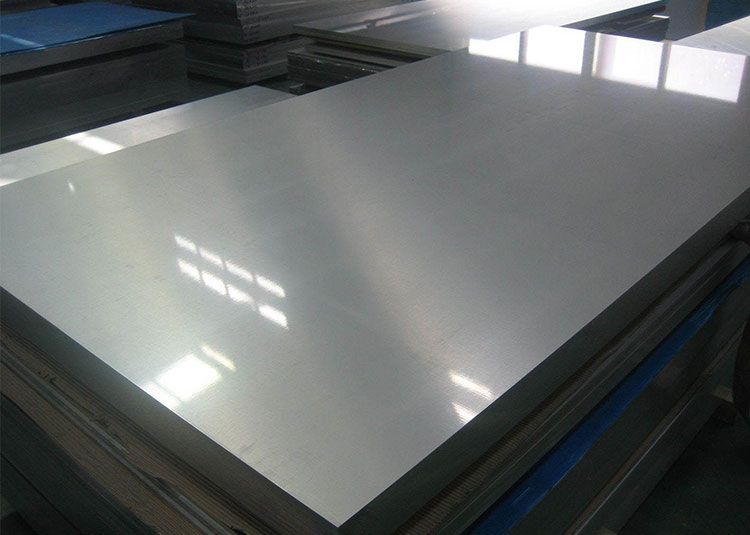

The first is the aluminum sheets material, aluminum manufacturers produce aluminum sheets is made of 0.5mm thick LF21 aluminum sheet processing. This type of aluminum sheets has a variety of the same material, similar to the shape, with the process of parts, while the same period of processing of similar parts of the shape did not appear such failure. And this is not the failure of raw materials caused by the failure. Then it is in the processing technology, on the cover of the silver line of the general process: machine plus pieces – pre-treatment – dip zinc – electroplating zinc – electroplating copper – electroplating silver – paint – dip 823 ─ storage.

In the aluminum plating process, first of all, there may be a certain part of the production process has changed, leading to failure. However, the survey found that in the production conditions did not change any situation, the same period of processing of similar parts did not appear such failure. As a result, the factors that change the plating conditions are excluded. According to the previous production experience, the most common cause of discoloration of silver plating is the effect of sulfur on silver plating.

In the past, there have been silver after the parts did not timely packaging and sealed to save, for a long time in the electroplating plant and lead to silver plating layer yellow. But the faulty parts are silver plated, are packaged in a timely manner and placed in a dry container to save, we can see that this is not affected by the plant air atmosphere. In the painting process, found the cover of the paint processing, there have been repeated records of the repair. The most important reason is that the gap is not blocked, so that paint mist into, and attached to the surface of the silver plating and can not be cleared. In order to prevent the occurrence of such failures, the process of processing, it is recommended to use 3M tape will be sealed to seal, to prevent the paint fog into.

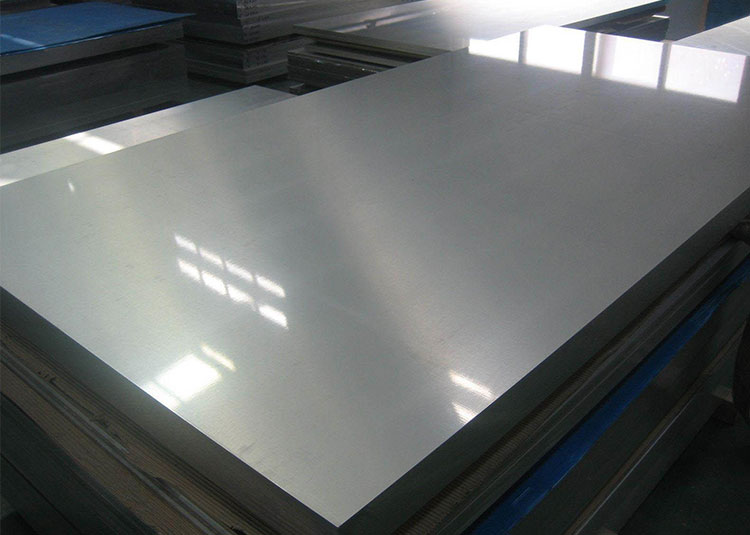

Through this method of exclusion, we found the root of the problem, we immediately take measures to eliminate the recurrence of hidden dangers, making the surface of the aluminum sheets as bright as the new factory rate greatly improved.